Unlocking the Potential of Power over Ethernet Plus in Industrial Networking

Enhancing Industrial Connectivity with Advanced PoE+ Solutions

In today’s increasingly interconnected industrial environments, the demand for efficient, reliable and industrial networking solutions is paramount.

Power over Ethernet (PoE) technology has emerged as a transformative solution, combining data transfer and power delivery within a single cable. This innovative approach has helped to simplify network infrastructures, reduce installation costs and enhance the flexibility of industrial automation systems.

Content overview:

- How does Power over Ethernet work?

- What Is PoE in Networking?

- Key Standards of PoE and PoE+

- Why PoE Technology is Essential for Smart Buildings and IoT?

- Leveraging PoE+ for Machine Vision Technology

- Flexible Communication Infrastructures Powered by PoE+

- HARTING’s Role in Future-Proof Industrial Networking

How Does Power over Ethernet Work?

PoE technology operates by transmitting both electrical power and data through standard ethernet cables, eliminating the need for separate power lines for connected devices.

Originally designed for powering devices such as IP cameras and VoIP phones, PoE has become essential for the deployment of advanced technologies like IoT devices, industrial automation, smart factories, Advanced connectivity, wireless access points and more.

What Is PoE in Networking?

For industrial networking, Power over Ethernet Plus (PoE+) offers enhanced capabilities by delivering greater power. While using the same Ethernet cables as PoE, PoE+ boosts power delivery to support more demanding devices while remaining backward compatible with legacy systems. Additionally, PoE+ is well-suited for Industrial Ethernet applications, ensuring compatibility with modern automation solutions.

Key Standards of PoE and PoE+

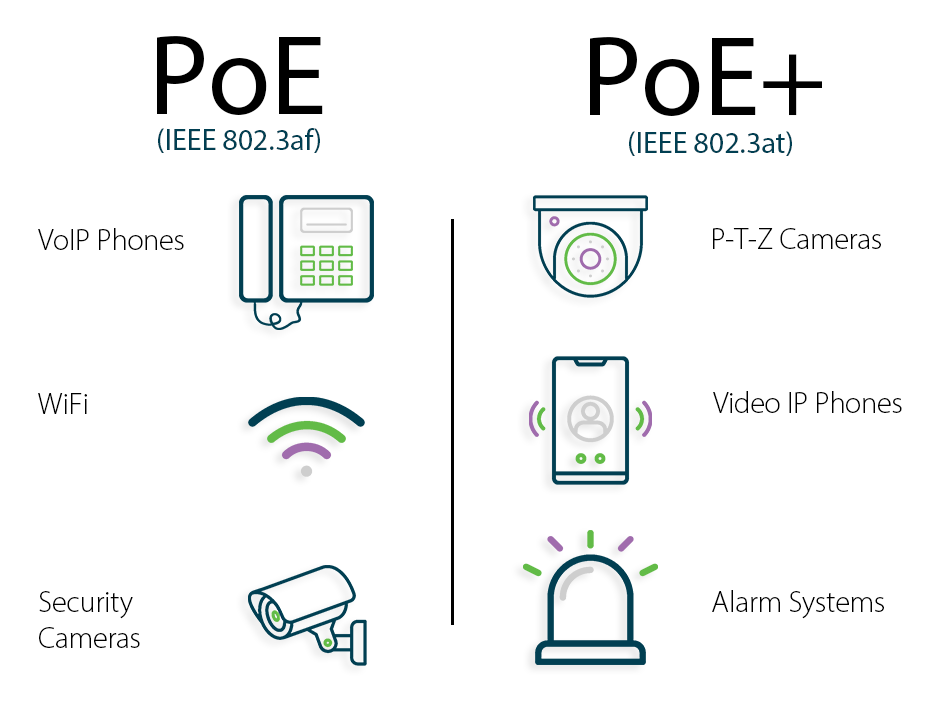

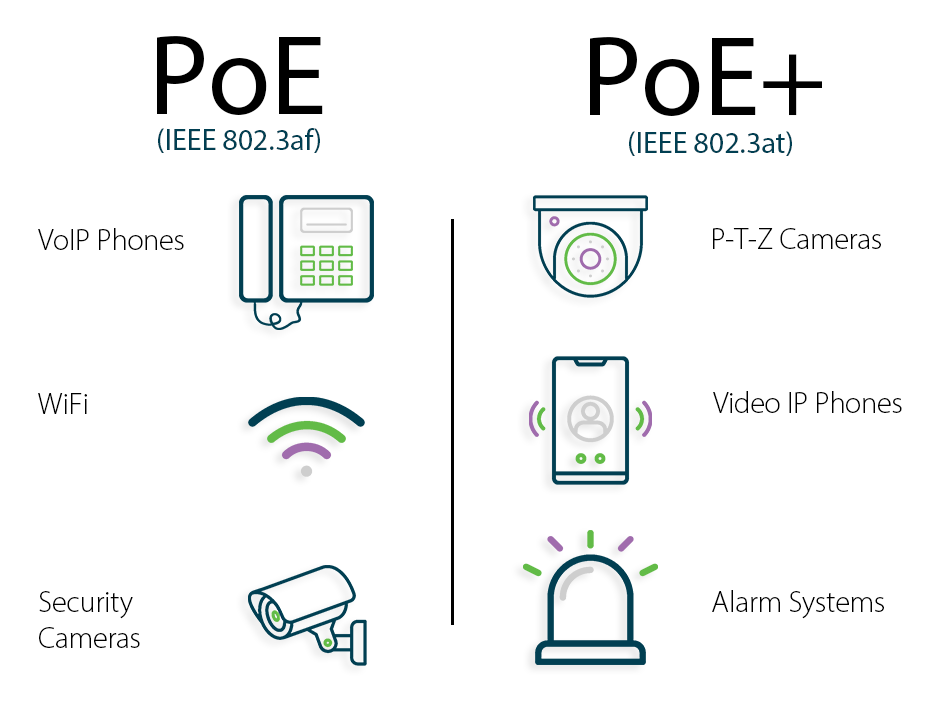

PoE (IEEE 802.3af):

PoE (IEEE 802.3af) Supports up to 15.4 watts of power per port, with a guaranteed minimum of 12.95 watts available to powered devices (PDs) after accounting for power loss in the cable. It is suitable for devices with lower power requirements, such as VoIP phones, basic IP cameras, and IoT sensors.

PoE+ (IEEE 802.3at)

PoE+ (IEEE 802.3at) An enhanced standard that provides up to 30 watts of power per port, with a minimum of 25.5 watts available to PDs. PoE+ is designed for devices with higher power needs, such as advanced IP cameras (with pan/tilt/zoom features), wireless access points and industrial equipment.

Why PoE Technology is Essential for Smart Buildings and IoT

Using PoE+ for the deployment of video surveillance systems offers a cost-effective, flexible and scalable solution for powering and connecting modern cameras. Whether safeguarding buildings or monitoring industrial machinery, PoE+ simplifies infrastructure, enhances capabilities and supports the seamless integration of advanced surveillance technologies.

Surveillance cameras can be used for more than just building security too.

Whilst cameras can be used for access control and perimeter monitoring and indoor security, cameras can also be integrated into Building Management Systems with PoE+ cameras working with automation systems to enable features like automated lighting based on motion detection.

There are also a whole host of machine surveillance benefits, such as industrial equipment monitoring. PoE+ cameras can be mounted on or near machinery to provide real-time video feeds for operators, ensuring equipment is functioning correctly and safely.

This leads on to predictive maintenance – where cameras equipped with thermal imaging or analytics can identify potential issues, such as overheating components, enabling preventive maintenance and minimising downtime.

Leveraging PoE+ for Machine Vision Technology

For more extreme environments, cameras can enable remote diagnostics, transmitting live footage from remote or hazardous locations to technicians, reducing the need for on-site inspections.

When using camera systems to monitor and control industrial manufacturing processes, it is commonly referred to as Machine Vision Technology, a critical enabler of Industry 4.0, empowering smart factories with real-time quality checks, automated processes and data-driven decision-making. Together, these technologies are transforming manufacturing into a more agile, efficient and intelligent ecosystem.

Flexible Communication Infrastructures Powered by PoE+

With the help of PoE+ and industrial switches, setting up a supplementary communication infrastructure within an industrial production facility can be swift, cost-efficient and flexible. From IP telephones to small servers to WLAN or Bluetooth access points, countless end devices can be used and networked.

Using a Single-Cable Solution lowers material and labour costs, particularly in large-scale installations. Devices can also be installed in areas without access to traditional power outlets, such as ceilings, outdoor spaces, or machinery setups. As a result, this can also help with the optimal placement of communication devices like access points, IP phones and cameras for improved network performance and coverage.

HARTING’s Role in Future-Proof Industrial Networking

Whether you’re designing a new facility or upgrading existing infrastructure, APC’s team of experts can help you understand PoE+'s potential and help you future-proof your industrial networking strategy.

Helping you to understand Power over Ethernet Plus’s potential

As a leading partner in the UK and Ireland to HARTING, APC offers advice and support to a wide range of networking solutions, such as HARTING’s Ha-VIS eCon series.

Ha-VIS eCon 3000 Ethernet Switches

Ethernet switches from the Ha-VIS eCon 3000 family feature up to 16 Fast Ethernet ports and offer economical and fast options to expand or set up network infrastructures. Full Gigabit Switches are available with up to 7 ports for applications with high data throughput. The slim design of the switches also allows them to be positioned on the carrier rail with a very high packing density. Thanks to the DIN rail that is integrated in the housing, the switches can be swiftly and simply installed in the field, which consequently helps save money and time.

Ha-VIS eCon 2000 Ethernet Switches

Equally, ethernet switches from the Ha-VIS eCon 2000 family offer up to 16 Fast Ethernet ports and are also available in a 7-port Full Gigabit version.

This allows customers to expand or setup network infrastructures in a time-saving, economical way. Owing to the extremely flat design, the switches can also be accommodated in installations where space is restricted towards the cable connection at the front. RJ45 ports are located on the front of the switches, allowing cables to be connected quickly and simply in combination with the flat design, this is genuinely unique.

Both switch families can handle Power over Ethernet Plus (PoE+), providing up to 4 x 34.2 watts for end devices. HARTING’s switches also integrate a DC/DC converter to allow the use of PoE+ with a switch supply voltage of 24 V DC. This saves time and cost expenditures for cabling and

also eliminates an additional power supply.

HARTING’s preLink® cabling system

To further enhance installation and network maintenance, HARTING’s preLink® cabling system is an all-purpose solution for IT, building automation and industry that can be used for all applications equally well. All preLink® connectors, sockets and the new PCB sockets have one thing in common: they can all be connected in seconds using the preLink termination block.

A unique functional feature – not available elsewhere – the preLink termination block allows for the separation of cable and connector into two units. The first unit consists of connectors, sockets, couplings or PCB terminals, all with an identical fixture for holding the preLink termination block, which forms the second part of the system.

About the Author

Richard Collins, MEng MIET

Operations Manager at APC Technology Group

As a member of our System division at APC Technology Group, Richard Collins is an expert in the field of modular device connectivity.

With more than 7,000 line items of industrial connectors, cable glands and accessories in stock, APC prides itself on customer service and fast quote and delivery times. More than 95% of orders are dispatched within 24 hours, in full and on time.

Contact us

Contact our team for technical advice and pricing support for your Power over Ethernet (PoE) and Power over Ethernet Plus (PoE+) requirements.