The Importance of Aircraft Lightning Protection

Lightning Protection Solutions for Airborne Applications in Compliance with RTCA DO-160 – Section 22.0, Level 3, 4 &5.

Content overview:

- RTCADO-160

- What is DO-160

- Two groups of tests may be used for equipment qualification

- Lightning Induced Transient Susceptibility

- Pin surge levels for Levels 3 and 4 are listed in a matrix of four separate pin injection threats shown below

- RTCA/DO-160G Table 22-2 Pin Injection Level 3

- RTCA/DO-160G Table 22-2 Pin Injection Level 4

- DO160 Level section 22 level 3 has been typically used for most aircraft but composites have necessitated level 4 and even level 5

- Components with Built-in Lightning Protection for Airborne Systems

- Beyond 4 Pin Surge Levels - DO-160 level 5

- TVS products to meet DO-160 level 5

When it comes to aircraft safety, lightning protection is a crucial aspect that must not be overlooked. It is speculated that airborne systems are struck by lightning at least once a year, therefore, airlines and manufacturers need to have reliable lightning protection measures in place.

Lightning strikes, whether positive or negative, on aircraft at low altitudes, could cause significant damage, leading to catastrophic failures.

When lightning strike's, high voltage and current will induce high voltage transients in power and signals of systems, such as flight control, actuation, navigation and communication equipment with potentially the worst consequences. It has been shown that systems with lightning protection have a significantly lower failure rate than unprotected systems.

Nowadays, specific flight critical systems generally use multiple redundancy, shielding and careful placement of cables to minimise effects but transient protection is a key part of the whole system.

In addition, the introduction of lightweight carbon composite fuselages has led to electrical issues as they create higher impedance in the outer skin, leading to differences in ground potential between different parts of the aircraft. Together with the reduced Faraday shielding effect, systems in these aircraft need to be capable of withstanding higher levels of lightning resilience.

In this article, APC will talk about ARINC 429 IC's Line Drivers and Line Receivers, which have been designed to comply with DO-160 pin injection testing and other avionics standards and how they make it easier to handle a wide range of protection schemes yet build a smaller lighter and lower cost system. Higher power bus systems will also need higher levels of transient protection, this article will briefly cover a range of high power lightning strike protection models of levels 3, 4 and 5.

RTCA DO-160

What is RTCA DO-160

DO-160, officially titled Environmental Conditions and Test Procedures for Airborne Equipment, is a document of environmental testing standards for airborne equipment. DO-160 is maintained and published by the Radio Technical Commission for Aeronautics or RTCA. DO-160.

This covers all aspects of aircraft safety and has been adopted by government agencies, avionic component suppliers, airlines and compliance testing facilities to establish industry-wide agreement on avionic security and reliability.

According to an Advisory Circular (AC) published by the FAA in 2011. RTCA / DO-160 has been used as an environmental testing standard for airborne equipment since 1958, when it was known as DO-130.

Two groups of tests may be used for equipment qualification:

The first is a damage tolerance test performed using pin injection. The second group evaluates the functional upset tolerance of equipment when transients are applied to interconnecting cable bundles but aren’t so relevant to PCB assemblies which integrate protection.

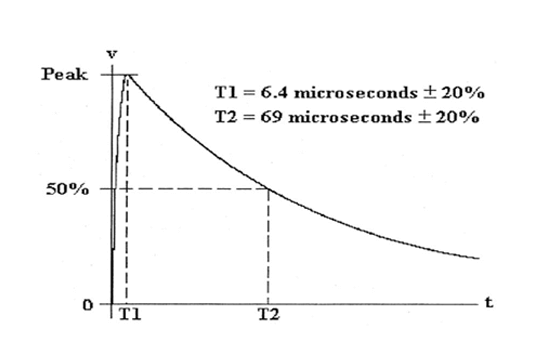

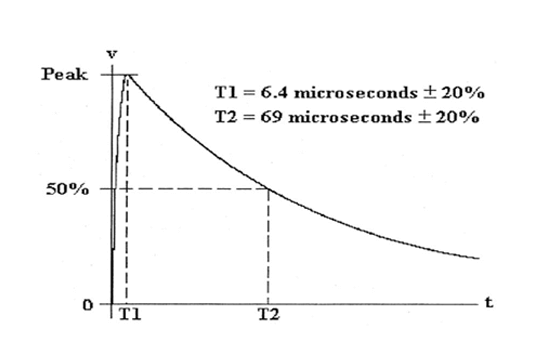

For lightning protection, Section 22 covers a set of injected waveforms which Level 3 and 4 cover the majority of Arinc 429 comms bus requirements.

Lightning Induced Transient Susceptibility

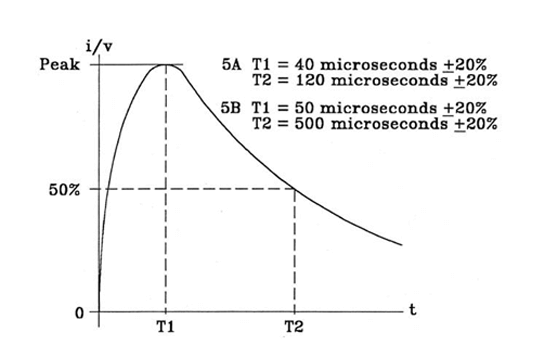

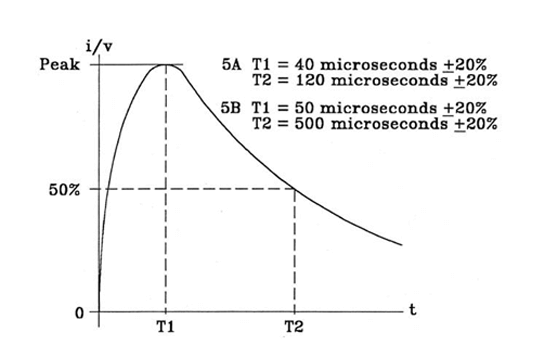

APC provides a range of integrated circuits with built-in Lightning Protection resistors and diodes to divert the high voltage and current of a lightning strike away from the sensitive avionics systems. In addition, network configurations of external resistors and TVS diodes have been developed to enhance protection justified by using the specific pin injection tests according to RTCA/DO-160G, Section 22, Level 3 and Level 4 pin injection test waveform set A (3 & 4), set B (3 & 5A) and set Z (3 & 5B).

Pin surge levels for Level 3 and 4 are listed in a matrix of four separate pin injection threats shown below:

RTCA/DO-160G Table 22-2 Pin Injection Level 3

| Level | Waveforms | |||

|

3 VOC/ISC |

4 VOC/ISC |

5A VOC/ISC |

5B VOC/ISC |

|

| 3 | 600/24 | 300/60 | 300/300 | 300/300 |

RTCA/DO-160G Table 22-2 Pin Injection Level 4

| Level | Waveforms | |||

|

3 VOC/ISC |

4 VOC/ISC |

5A VOC/ISC |

5B VOC/ISC |

|

| 4 | 1500/60 | 750/150 | 750/750 | 750/750 |

DO160 Level section 22 level 3 has been typically used for most aircraft but composites have necessitated level 4 and even level 5

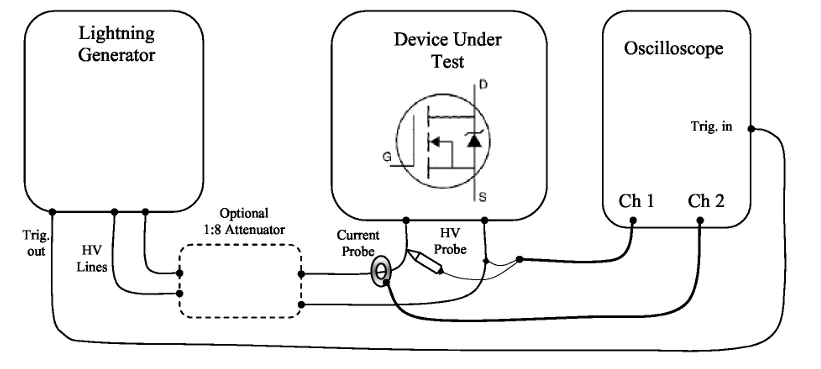

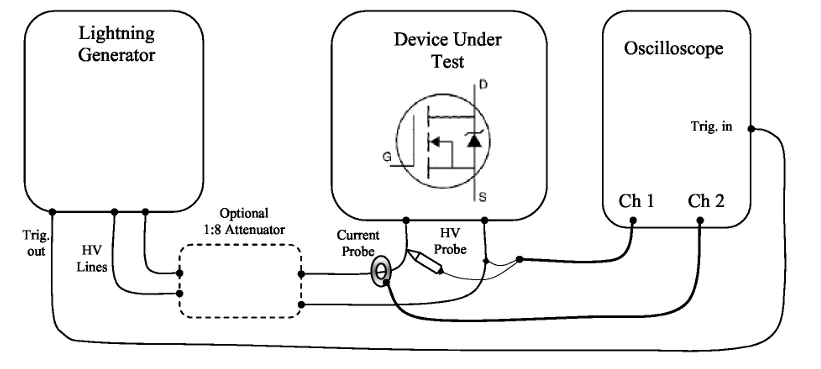

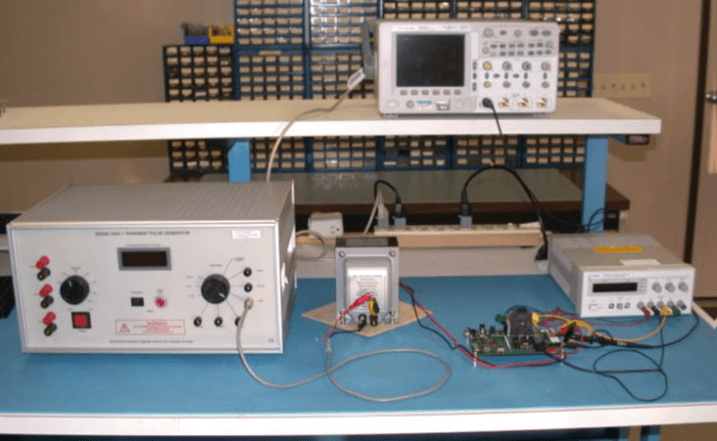

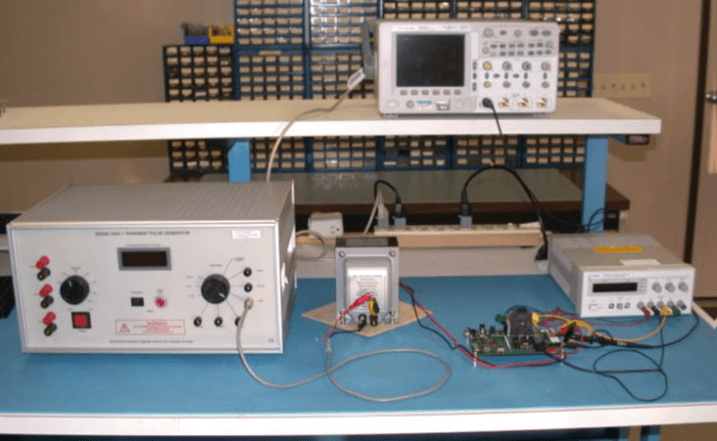

In the specific tests below (Figure 3.) a solar model lightning generator has been powered up and inputs or outputs are subjected to pin injection. A transient generator is used with a transformer. The waveforms are calibrated through a coupling impedance. For example Waveform 3 600V with 24Amps through 25 ohms.

Waveform 4 requires A 300V 60 amp pulse through 1 ohm. Tests reference circuit board ground rather than a chassis ground. ARINC 429 parts are either receivers RX, transmitters/drivers TX for example the the HI-35930 carry SPI bus, 2 x RX and 1 x TX.

The main point is that this IC provides level 3 protection using five external components if desired. This includes two receive series resistors and a network of two bidirectional TVS diodes, along with four resistors. Earlier models, such as the HI-3582 introduced in 2009, would have also required 15V Zeners.

The output resistors which have tended to be wirewound and quite large as they have to be higher power typically 1-5 Watt resistors but have an open circuit failure mode as a last resort so not using them is able to reduce pcb board space.

However when it comes to Level 4 systems, In the case of the HI-35930, these parts do still require external protection but the additional built in resistors make it easier to implement.

The HI-35930 also has internal 5ohm resistors for the driver and 40K ohm resistors built into the receivers to implement a minimal external network. The receivers would require two bidirectional 1500kW 5v Zeners, typical characteristics of a TVS. The clamp voltage is specified as a minimum and maximum, but higher than the breakdown voltage. Breakdown must be selected beyond the normal operation of the circuit but catch the transient.

TVS are chosen over metal oxide varistors as they tend to have lower leakage and no degradation when used in limits and self-extinguishing.

Components with Built-in Lightning Protection for Airborne Systems

Whilst it is possible to use an external network of components for protection, as much of the network is already implemented, it helps reduce component count.

There are several screening options covering extended temperature and mil screening. The networks recommended have a lower power consumption and higher reliability due to lower part count as well as maintaining compliance with ARINC specifications.

Beyond 4 Pin Surge Levels - DO-160 level 5

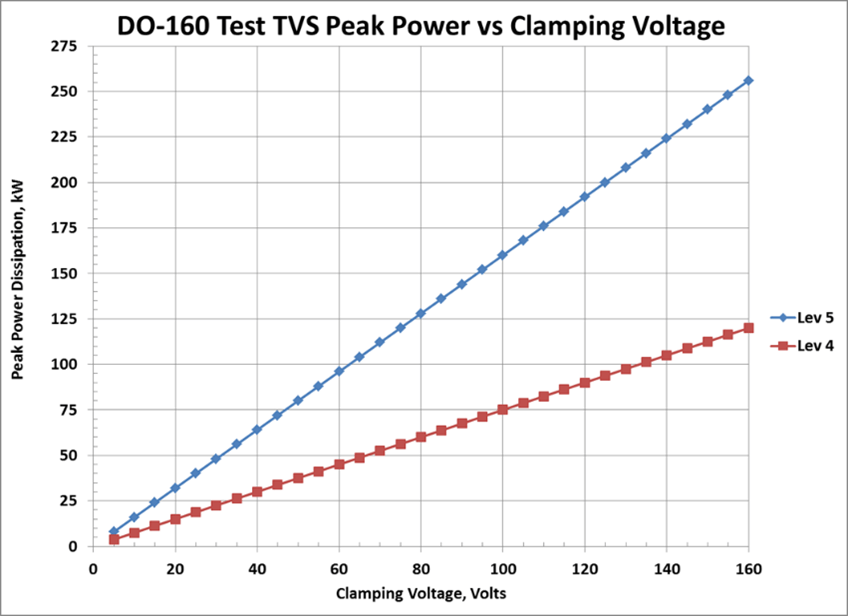

To achieve level 5, level 5 power for example in power bus systems higher peak power units are needed.

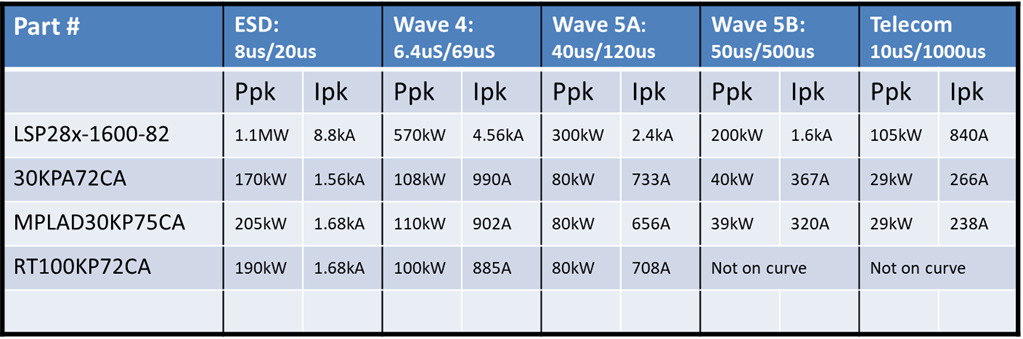

As an example, products like the LSP28A-1600-41 are designed for 28V bus systems and meet DO-160 level 5 to a blocking power of 100KW and 1600 Amps peak current yet keep small profiles. It is possible to scale up the level 4 and 5 tests.

Other high-power TVS are available for faster applications with lower capacitance. It must be noted that for higher power TVS, with high power and longer durations with elevated temperature, derating might also become a factor, this can vary from manufacturer to manufacturer. To get higher voltages and higher current, it is possible to stack in series and parallel TVS devices.

APC provides a range of high-power TVS products to meet DO-160 level 5

APC partners with leading technology manufacturers from around the world to offer expert advice and technical insight on a wide portfolio of solutions for Lightning Strike Protection in Composite Frame Aircraft. Contact a member of our team today to find out more about our DO-160 Level 5 Components.

Get expert advice

Customers can contact a member of APC's high-reliability components team for more information about APC's lightning protection mil-std components for airborne systems.

Working directly with leading avionics manufacturers, APC provides a vast selection of RTCA DO-160G (levels 3-5) waveform-compliant components. At APC, we prioritise fast, cost-effective delivery, shortening your time-to-mission and reducing expenses. As a part of the ADS Group, APC is your trusted source of authentic mil-std components.

About the Author

Richard Hough

Technical Director at APC Technology Group

Richard Hough, with over 30 years of experience in avionics, PCB, space components, and FPGA technology, is a leading expert in APC Technology Group's high-reliability division.