Connectivity infrastructure for hydrogen technologies from HARTING

- Richard Collins

- Insights & Events

- 21 Nov 2023

Harting's configurable components and system solutions for the hydrogen market

The hydrogen market has the most demanding quality requirements regarding safety, durability and reliability. This is precisely why HARTING is your optimal partner for connectivity for hydrogen technology; their incentive is to develop products and solutions efficiently and sustainably.

Connectivity – Connection technology for transmitting data, signals and power

Decisive in creating an energy supply for the future. It is critically essential in hydrogen production because the efficient networking of all components and systems being used, ensured by connectivity, is necessary to implement an effective cycle in the production and distribution of hydrogen. Similarly, the connectivity infrastructure between hydrogen producers and consumers plays a crucial role in hydrogen technology.

What connectivity do HARTING offer in the hydrogen production?

- HARTING components simplify the scaling of electrolysis facilities

- Developing connectivity options that are perfectly suited for electrolysis systems

- Due to high-temperature fluctuations, continual monitoring of all process signals (such as pressure, temperature and flow measurement) is required

- By taking advantage of the right connectivity, reliable voltage monitoring is possible even at high ambient temperatures

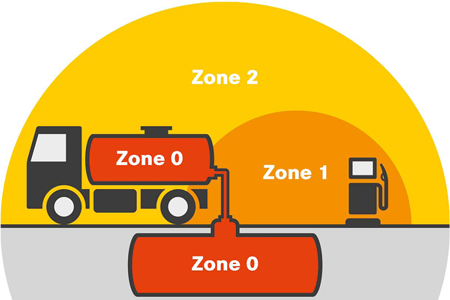

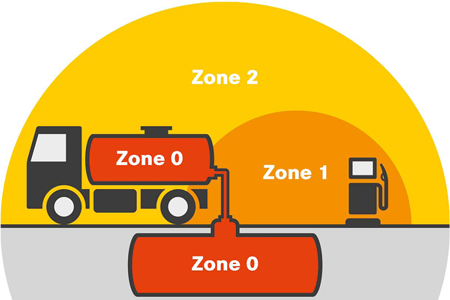

What connectivity do HARTING use to support the transport and storage of hydrogen?

- HARTING offer system solutions for connectivity in transport with mobile storage units

- Customised, custom-fit and space-saving connectivity for monitoring the temperature, pressure and valve positions

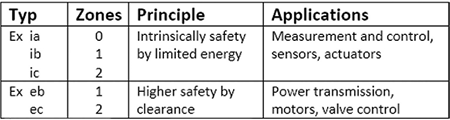

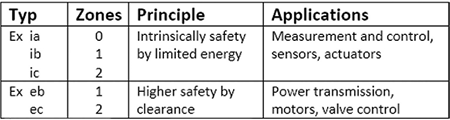

- Also available as intrinsically safe Ex-i solutions for all signals

- Valve control using pneumatic connections is possible

- Customised and space-saving connectivity boxes are available in stainless (V2A and V4A) or powder-coated steel

In which areas is HARTING connectivity used?

Fuel cells for railroad technology

- Complete cable assemblies that are tested according to railroad standards

- Reliable and durable HPR® hoods/housings for the most demanding environmental requirements

- Assemblies are individually configurable according to your application requirements

Fuel cells for the marine sector

- For these applications, HARTING offers solutions similar to hydrogen transport with mobile storage units

- A comprehensive product portfolio for transmitting signal, data and power – in proven HARTING quality, tested and documented

- Also available as a complete solution

Co-Tron Components is a part of APC Technology Group.

For 34 years, Co-Tron have been a trusted distributor of Harting products, over this time they have built a strong partnership for the distribution of connectors and interconnection systems.

As well as the hydrogen technology connectors, Harting manufactures a wide selection of connectors, Ethernet solutions, cabling and customisable solutions for a variety of applications.

For advice and technical support ask a member of our team:

0330 313 3220 | [email protected]

A global market leader in the manufacture of connectors and interconnection systems is renowned for its reliable connector solutions. HARTING’s products cover data processing, control and measurement applications within industrial machinery, food and beverage equipment, rail, automotive, energy distribution, wind power and robotics.