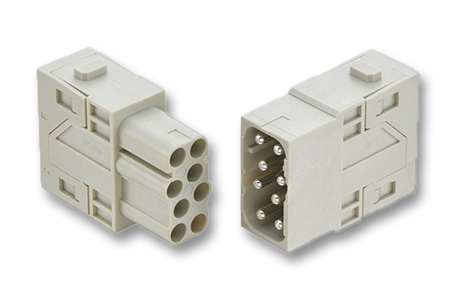

Han Push-In termination modules expand the broad HARTING range

- Richard Collins

- Insights & Events

- 4 Jul 2023

The new tool-less termination technology from HARTING can reduce assembly times by up to 30% and improves flexibility in the field.

In addition to the global megatrend of sustainability, HARTING is also addressing other challenges faced by its customers, such as demographic change and the associated shortage of skilled workers. Therefore, their solutions are always characterised by an efficient plug & play assembly, which eliminates errors by ensuring plug-in security with the help of coding. HARTING offers the largest variety of termination technologies on the market.

With the Push-In technology, HARTING are now expanding this portfolio.

Up to 30% less assembly time for field installation

The Push-In connection technology is a further development of the cage clamp connection and expands the portfolio of Han® industrial connectors with an additional field connection method. The focus is on fast and uncomplicated assembly of the connector with consistent quality and robustness.

A wide selection of inserts from the Han® portfolio is available, providing numerous solutions for different customer requirements.

Push-in connection technology also allows you to assemble several conductor variations. The selection ranges from stranded conductors to conductors with ferrules (insulated/uninsulated) and solid conductors.

The range of conductor selection is as broad as possible to enable the use of this flexible termination technology across many different market segments.

Easy handling due to tool-less termination

The expansion of the Han® portfolio to include the Push-In termination technology is the perfect complement to quick, flexible working practices in the field.

Thanks to the tool-free assembly, no further steps are required in the preparation of the assembly, which saves time, resources, and costs.

It also allows the easy handling of components in limited installation spaces, such as maintenance work on wind turbines. Push-In technology is ideally suited to areas where a high degree of flexibility is required, such as when changing tools on machines. This can be done simply, quickly and without the need for tools.

Benefits at a glance:

- Up to 30% less assembly time with direct insertion of the conductor into the contact chamber

- Easy handling due to tool-less termination

- Cost savings compared to alternative termination technologies

- Maximal flexibility - suitable for ferrules, stranded wires and solid conductors

- Compatible with identical products with other termination technologies

HARTING's entire range of connector solutions are available from Co-Tron Components, a part of APC Technology Group.

With thousands of items in stock and available for next-day delivery, speak to one of our HARTING experts for more information, project support and pricing.

01634 719 799 | [email protected]

A global market leader in the manufacture of connectors and interconnection systems is renowned for its reliable connector solutions. HARTING’s products cover data processing, control and measurement applications within industrial machinery, food and beverage equipment, rail, automotive, energy distribution, wind power and robotics.