SCIF Design and Construction Services

Designed and Engineered to Meet MIL-STD, DEF-STAN, SDIP, ICD 705 and ISO Standards for Aerospace, Government and Defence Applications

APC provides a fully bespoke SCIF (Sensitive Compartmented Information Facility) design and build service, offering turnkey project delivery led by an experienced, accredited team. Recognising that every SCIF project is unique, we follow a clear, stage-based approach aligned with the RIBA Plan of Work. This ensures a reliable, standards-compliant solution tailored to each client’s operational and security needs.

Our SCIF solutions comply with stringent standards including MIL-STD-188-125, DEF-STAN-59-188, SDIP-29 and are ISO-compliant for transportation, safety and quality management. Shielded containerised solutions can also be designed for data centres and mission-critical environments, with optional RFI shielding incorporated where required.

SCIF Design & Delivery Process

Stage 0 / Stage 1 – Strategic Definition & Briefing

Scoping Out: Defining Your SCIF Requirements and Compliance Goals

Engagement begins with a consultation (phone, online or in person) to establish the project’s purpose, operational needs, attenuation requirements, size, location, budget and internal finishes. We define the compliance framework from the outset, referencing ICD 705, JSP 440, TEMPEST, MIL-STD-188-125, DEF-STAN-59-188, and others as relevant. Early risk and compliance objectives are set, guided by our experience across defence and secure infrastructure projects.

Stage 2. Concept Design

Project Development: Establishing the Design Framework

Our team develops the initial concept design, selecting shielding methods, HVAC strategies, and security systems. Spatial layouts consider workflow, equipment, and personnel movement, with integration of physical and electronic security. Concepts reference standards including ASTM E1851 (shielding), UL 752 (ballistic resistance, if required), ISO 14644-1 (cleanrooms), and ISO 9001 (quality management).

Stage 3. Spatial Coordination / Design Development

Programme and Compliance Milestones

Following approval of the design brief, we create a coordinated project programme, including milestone reviews for compliance, design sign-off, procurement, and testing. A cost plan is developed alongside scheduling. Compliance with BS EN 50522 (earthing), BS 7671 (electrical), NFPA 70 (safety), and ISO 21500 (project management) ensures a transparent and robust delivery plan.

Stage 4. Technical Design

Detailed Design and Security Engineering

Comprehensive technical drawings and 3D models are produced, specifying RF shielding systems, acoustic treatments, HVAC routing, fire protection, waveguide penetrations, and grounding. Documentation is fully standards-referenced, including MIL-STD-285/IEEE-STD-299 (RF testing), BS EN 13501 (fire safety), and ISO 12944 (corrosion protection), ensuring seamless transition to manufacture and installation.

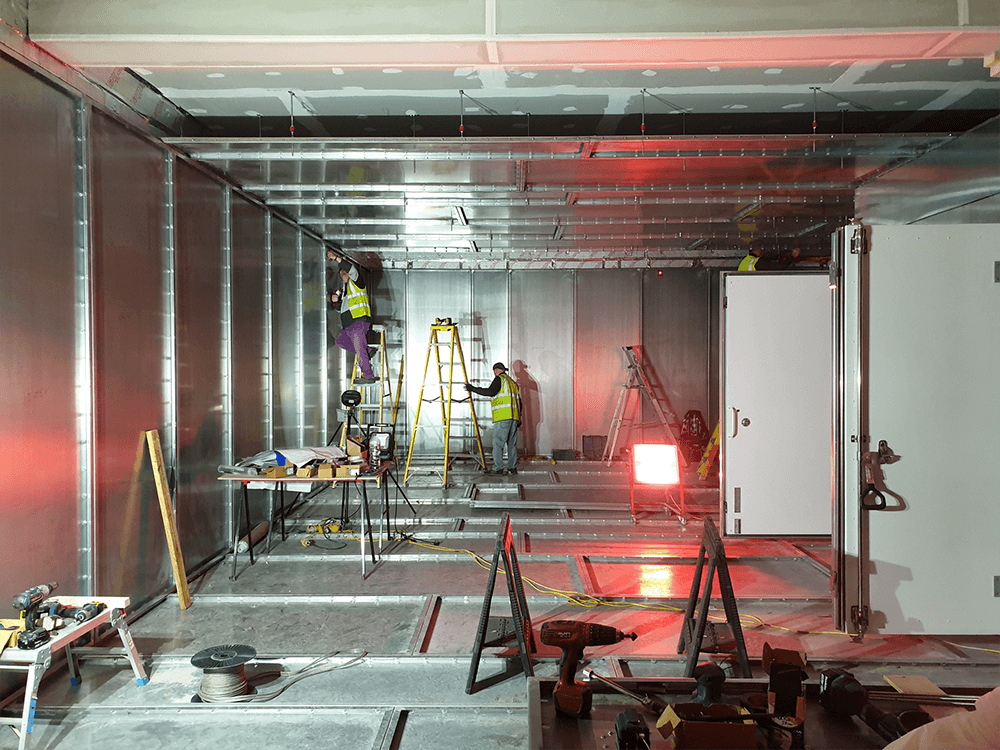

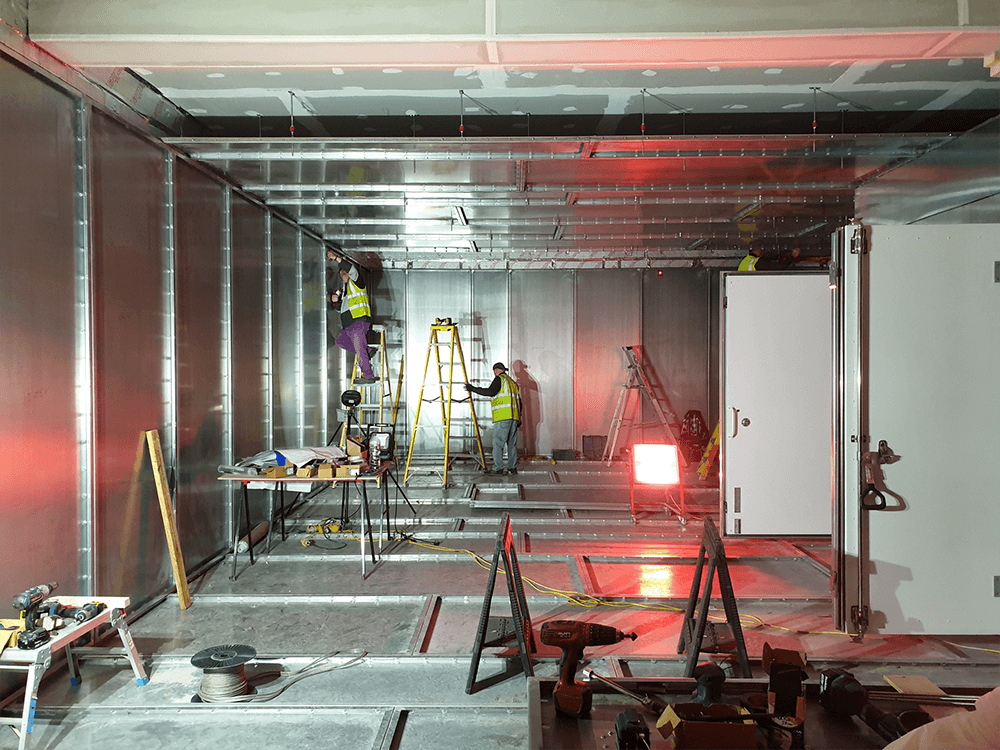

Stage 5. Manufacturing & Construction

Installation: Precision Build and On-Site Assembly

Fabrication of panels, doors, filters, vents and other components is undertaken in controlled conditions to guarantee performance. On-site construction is closely supervised, ensuring shielding continuity, safe integration of MEP systems, and compliance with EMC and safety regulations. Relevant standards include ISO 14694 (ductwork), BS EN 50147-1 (shielding), and OSHA/CDM Regulations (site safety). Quality checks are embedded throughout.

Stage 6. Handover & Close Out

Testing, Certification and Client Documentation

All facilities undergo rigorous testing before handover. This includes:

- RF Shielding: IEEE-STD-299

- Acoustic Attenuation: ASTM E336, ISO 10140

- Safety & Systems: Electrical, fire, environmental and TEMPEST compliance

Testing is carried out under ISO/IEC 17025 guidelines, with full reporting and certification. Clients receive a comprehensive documentation pack including test results, compliance statements, and ongoing maintenance recommendations.

Stage 7. In Use

Post-Completion Support

Our service extends beyond handover, with maintenance, inspection, and upgrade options to ensure continued compliance and operational reliability throughout the SCIF’s lifecycle.

Bespoke Features

- EMP Shielding: Protecting against electromagnetic pulse (EMP) to safeguard against interference caused by nuclear explosions.

- RF Shielding: Enhanced to prevent signal leakage and electronic eavesdropping.

- Soundproofing & Acoustic Treatments: For superior acoustic security.

- Environmental Control Systems: Including precise HVAC systems to regulate temperature, humidity, and air quality.

- Integrated Secure Systems: We also offer secure communication solutions, including encrypted phones and video conferencing equipment, tamper-resistant furniture, and secure document storage options, all designed to maintain confidentiality.

- Redundancy & Fail-Safe Features: Ensure continuous operation with systems like UPS, backup power generators, and more, so your SCIF is fully operational, even during power outages or system failures.

Optional Extras for Enhanced Security

- Smoke & Heat Detectors: Compliant with BS 5839 for fire detection.

- Pneumatic Door Controls: Ensuring smooth, precise door movements.

- Interlocking Doors: Prevent unauthorised access.

- Visitor Management Systems: Secure biometrics and access control.

- Secure IT & Network Equipment: Including high-security multifunction devices and network security.

- Emergency Escape Routes: Secure, authorised emergency exits.

- Surveillance & Access Control: Video monitoring and biometric systems.

Tailored Designs for Your Operational Needs

Every SCIF we deliver is designed and built to meet the specific operational and security requirements of our clients. From bespoke internal finishes to complete electrical installations, HVAC systems, UPS units, and even solar power integration, we ensure each facility is optimised for its intended environment. Our design process allows for mission-specific layouts, workflow efficiency, and future-proofing so your SCIF remains secure and functional for years to come.

Genuine SCIF Components, Sourced from Leading Manufacturers and Fully Traceable to Origin

Our SCIF containers typically form the primary RF shield, constructed by licensed and highly experienced welders. We also employ a 3-part paint system, favoured by offshore and marine industries for maximum durability. All SCIF units are accredited by a Cognisant Authority (CA) such as the MoD or Cabinet Office before they can be used. Each container project we work on is custom-made to meet unique requirements. From internal finishes to the full electrical package, HVAC systems, UPS, solar power and everything in between, we ensure that each SCIF meets your operational and security needs.

Explore APC's Range of Comprehensive SCIF Solutions

Ask a Member of our Expert Team

Have more questions regarding SCIFs - or need advice and support for planning your own Secure Compartmented Information Facility? Our team are on hand to answer your questions and share the technical insight we have to ensure you meet your project requirements.

Request a callback from a member of our technical team to get dedicated one-to-one consultancy for your SCIF requirements.

Your Certified Partner for Secure, Compliant SCIF Projects

With 40+ years’ experience, APC Technology Group supplies genuine, traceable MIL-STD components and systems for Naval, Land and Avionic applications. As a distributor for 100+ specialist manufacturers, we deliver secure, high-reliability solutions backed by BS EN 9120, ISO 9001, Cyber Essentials Plus, AS9120 and ADS Group accreditation, ensuring trusted quality and compliance for mission-critical projects.