Voltage Dip Testing for Electromagnetic Compatibility (EMC)

What EN 61000-4-11 requires and how to test voltage disturbances

Voltage dips, also known as voltage sags, are among the most common and disruptive power-quality events encountered by engineers.

To ensure proper immunity of equipment to such events, international EMC standards EN 61000-4-11 specify standardised test procedures and performance criteria for evaluating the effects of voltage dips, short interruptions and voltage variations.

In this guide, we will cover the test methods used, real-world causes, performance criteria, common failure modes and how to build an in-house test capability using the Haefely DIP 116.

What are voltage dips, interruptions and variations, and how are they caused?

Voltage dips, interruptions and variations are three types of short-term power disturbances defined in EN 61000-4-11. An overview of each is defined below:

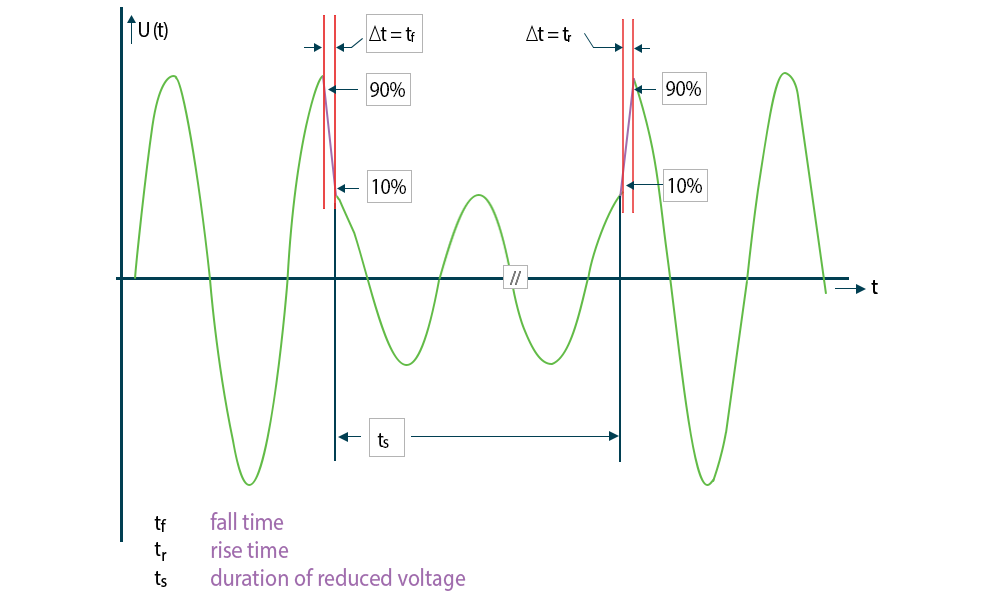

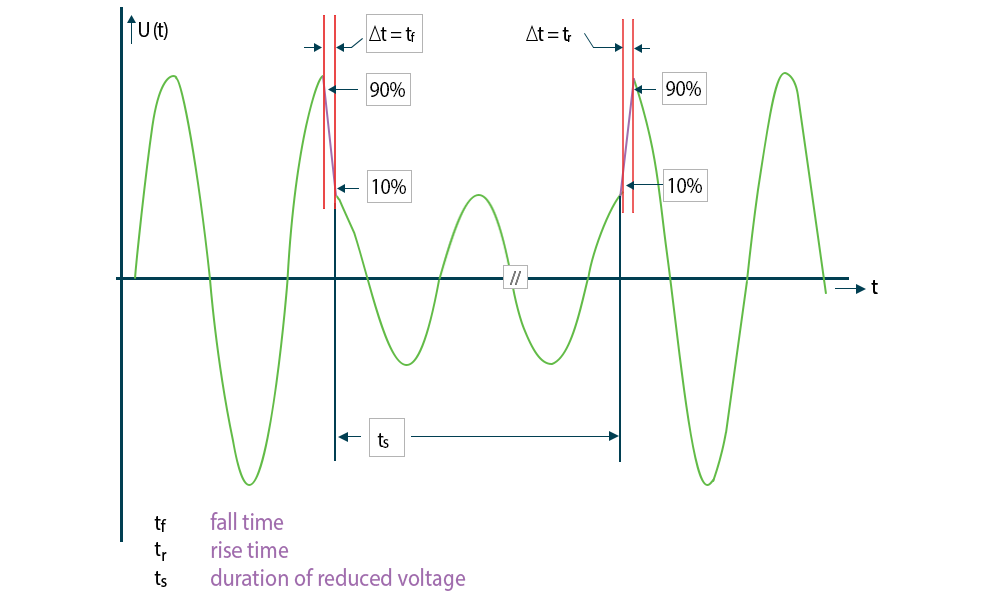

Voltage dips

Voltage dips or sags are sudden reductions in voltage at a specific point in an electrical supply system. The supply voltage dips below a specified threshold for a brief interval before restoration to its original level. Typical causes of voltage dips (or sags) occur in network faults (short circuits), large load changes, motor starts and transformer energisation.

Voltage variations

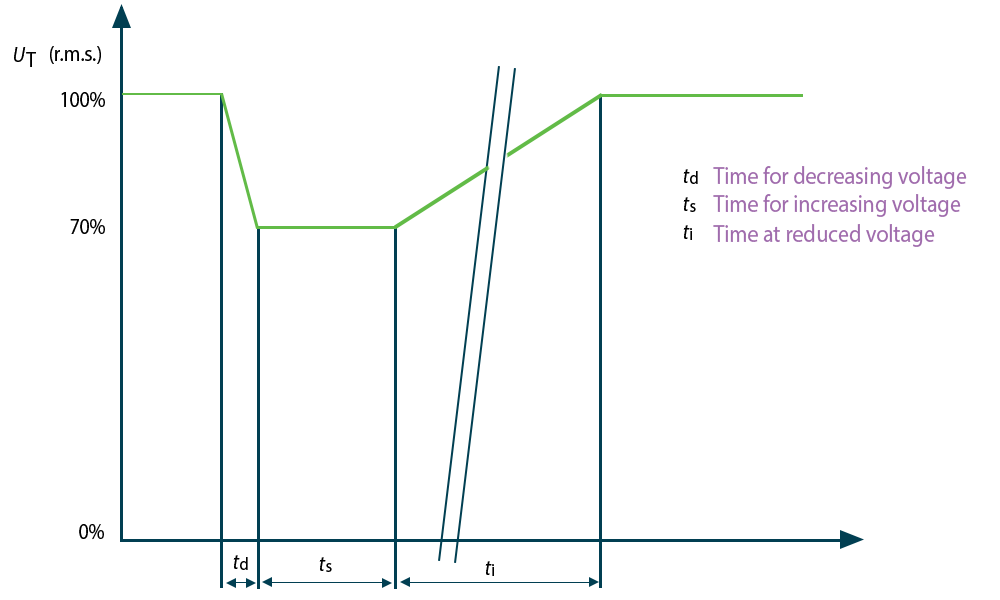

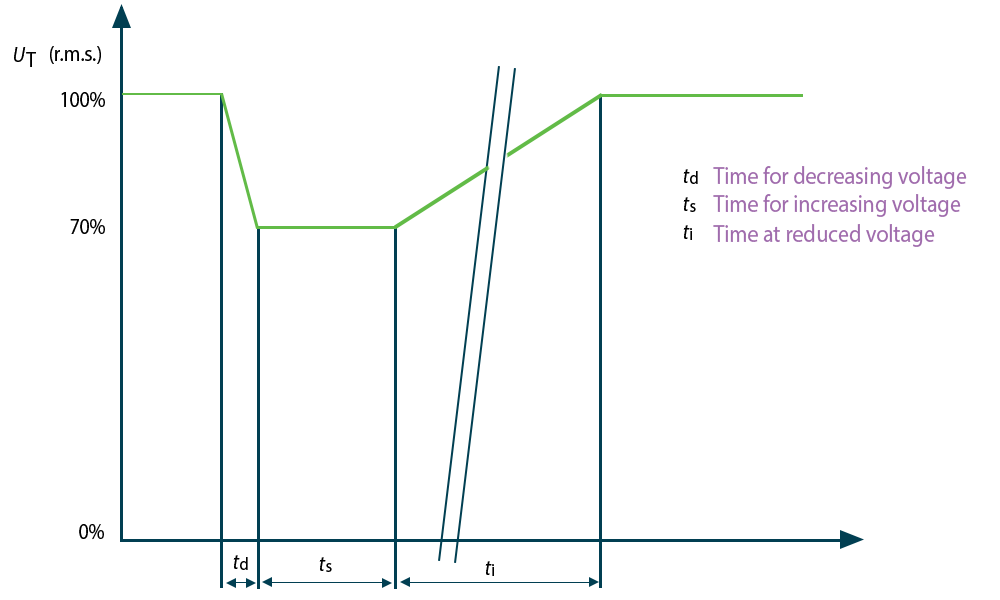

Voltage Variations (figure 1) are gradual shifts in voltage from nominal levels to higher or lower values for short or extended periods. Typical causes of voltage variations include varying or cyclic loads, mechanical relay activity, large sustained loads and brownouts.

Voltage Interruptions

A short interruption (figure 2), as defined by EN 61000-4-11, is a sudden drop in supply voltage on all phases at a specific point within a supply system below a designated interruption threshold. After a brief period, the voltage returns to its original level. Similar to voltage dips, short interruptions are typically caused by the occurrence and cessation of short circuits on the system or connected installations.

Test classes EN 61000-4-11

The test classes outlined in EN 61000-4-11 specify the disturbance severity levels a device must withstand, representing conditions from stable residential supplies to challenging industrial networks. Each class's specific test levels, applicability and performance requirements are defined by product committees, which interpret the standard for their particular equipment categories.

This ensures that testing remains consistent with real-world usage while avoiding unnecessary requirements for products that do not operate in harsher conditions.

Class 1: Stable, well-regulated environments

Equipment intended for environments where the mains supply is clean, predictable and unlikely to experience severe dips or interruptions.

Examples of class 1 equipment:

- Laboratory or calibrated test instruments

- Studio/office AV or IT systems on conditioned power

- Medical analysis devices powered by regulated hospital supplies

Class 1 assumes low disturbance probability, so the test levels are less severe.

Class 2: Typical public low-voltage networks (most products)

Equipment connected to general-purpose mains supplies where moderate dips, short interruptions and voltage fluctuations occur regularly.

Examples of class 2 equipment:

- Domestic appliances and home electronics

- Office IT equipment (PCs, monitors and printers)

- Commercial HVAC and building-control devices

Class 2 reflects “normal” real-world conditions for the majority of consumer and commercial products.

Class 3: Harsh or industrial environments

Equipment expected to operate where supply disturbances are frequent and severe, often due to large loads, machinery, high inrush currents or switching operations.

- Examples of class 3 equipment:

- Industrial automation systems (PLCs, HMIs)

- Motor drives, pumps and compressors

- EV chargers and heavy power-conversion equipment

Class 3 requires the highest immunity levels, as voltage dips and interruptions are common in these environments.

Class X: Custom requirements defined by product committees

Used when neither class 1, 2, nor 3 accurately reflects the equipment’s operational demands. The product committee or manufacturer specifies the exact dip levels and durations.

Examples of class X applications:

- Railway signalling or transportation electronics

- Life-support or other critical medical devices

- Defence, aerospace or mission-critical equipment

Class X is used when the operational environment is unique or safety-critical and requires tailored immunity levels.

EN 61000-4-11 test levels

EN 61000-4-11 sets the test levels for voltage dips, short interruptions and voltage variations for equipment with a rated input current of up to 16 A per phase. The specific test levels and durations depend on the product's class, which is defined by the product-specific standards as mentioned above.

The tables below reflect a different kind of stress on the internal power architecture, exposing weaknesses that are often invisible during normal operation. Understanding what these tables mean in practical engineering terms helps teams interpret failures and design more robust systems.

Preferred test levels and duration for voltage dips

|

Class a |

Test levels and durations for voltage dips (ts) (50Hz / 60Hz) |

||||

|

Class 1 |

Case-by-case, according to the equipment requirements |

||||

|

Class 2 |

0% during ½ cycle |

0% during 1 cycle |

70% during 25/30c cycles |

||

|

Class 3 |

0% during ½ cycle |

0% during 1 cycle |

40% during 10/12c cycles |

70% during 25/30c cycles |

80% during 250/300c cycles |

|

Class Xb |

X |

X |

X |

X |

X |

|

a Classes as per IEC 61000-2-4 b To be defined by product committee. For equipment connected directly or indirectly to the public network, the levels shall not be less severe than class 2. c "25/30 cycles" means "25 cycles for 50 Hz test" and "30 cycles for 60 Hz test". |

|||||

Table 1: Test levels and durations for voltage dips

Test levels and durations for short interruptions

|

Class a |

Test level and durations for short interruptions (ts) (50Hz / 60Hz) |

|

Class 1 |

Case-by-case, according to the equipment requirements |

|

Class 2 |

0% during 250/300c cycles |

|

Class 3 |

0% during 250/300c cycles |

|

Class 3 |

X |

|

a Classes as per IEC 61000-2-4 b To be defined by product committee. For equipment connected directly or indirectly to the public network, the levels shall not be less sevre than class 2. c "250/300 cycles" means "250 cycles for 50 Hz test" and "300 cycles for 60 Hz test". |

|

Table 2: Test levels and durations for short interruptions

|

Voltage test level |

Time for decreasing voltage (td) |

Time at reduced voltage (ts) |

Time for increasing voltage (ti) (50Hz/60Hz) |

|

70% |

Abrupt |

1 cycle |

25/30b cycles |

|

Xa |

Xa |

Xa |

Xa |

|

a To be defined by product committee. b "25/30 cycles" means "25 cycles for 50 Hz test" and "30 cycles for 60 Hz test". |

|||

Table 3: Timing of short-term supply voltage variations

Together, the three tables provide a complete picture of resilience across fast collapses, total outages and long-duration low-voltage conditions. Testing for these events helps engineers verify that equipment remains stable or recovers safely when the mains supply fluctuates unexpectedly.

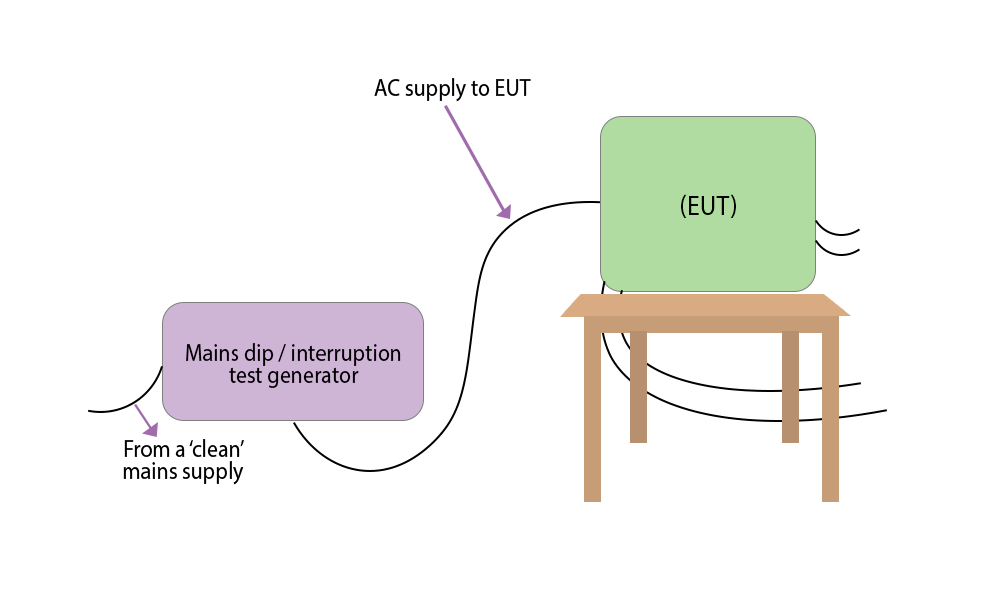

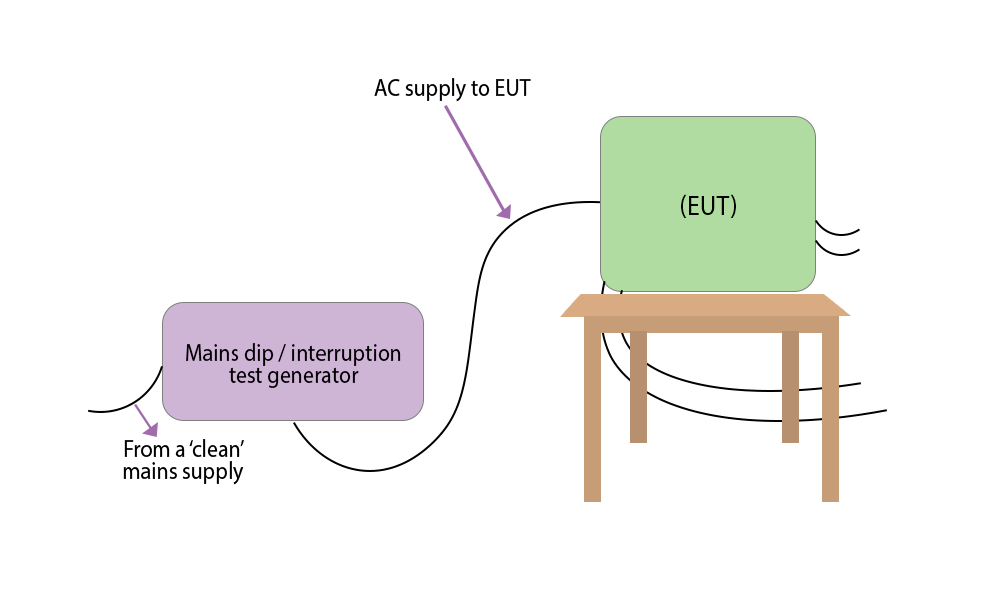

EN 61000-4-11 test procedure and test setup

Equipment required for EN 61000-4-11 test setup

A compliant setup includes:

- A stable AC source

- A dip/interruption generator (e.g., Haefely DIP 116)

- Monitoring equipment for voltage and current

- Ground reference plane

- Proper cable routing and loading conditions

Test overview EN 61000-4-11 pass/fail criteria

The purpose of this standard is to assess the impact of voltage dips, short interruptions and voltage variations on equipment connected to public distribution networks. It aims to establish whether the equipment under test (EUT) has a robust enough design to withstand or be immune to these power quality events.

The pass/fail criteria in EN 6100-4-11 categorise test results into four groups to assess the impact of voltage dips on the EUT.

- Performance criteria A - Performance within specification limits

- Performance criteria B - Temporary degradation, which is self-recoverable

- Performance criteria C - Temporary degradation which requires operator intervention

- Performance criteria D - Loss of function which is not recoverable

Why manufacturers must comply with EN 61000-4-11 standards

EN 61000-4-11 compliance is not optional in most regulated markets. OEMs must ensure their equipment can:

- Resist sudden voltage fluctuations

- Perform a clean restart after a voltage interruption

- Ensure safe and reliable operation without data corruption, loss of functionality or endangering users

Failure to comply can result in:

- Deployed product launches

- Rejected certification applications such as CE, FCC, CCC, etc

- Liability risks in safety-critical environments

- EN 61000-4-11 test procedure

How EN 61000-4-11 testing is performed in practice

While EN 61000-4-11 defines the test levels and durations, the practical execution of the test is where many product teams struggle and where in-house capability becomes important. Below, we will walk through what happens during a test:

- The voltage is reduced or removed at controlled zero-crossings

Whether you’re using a Variac or a fully automated generator, the voltage transition must align with the AC waveform’s zero-crossing point. This prevents distortion and ensures the disturbance replicates real-world grid behaviour. - Each disturbance is applied three times

The standard requires three repetitions per level, separated by 10-second intervals, so engineers can determine whether the failure is random, thermal, timing-related or systemic. - The EUT is monitored before, during and after each event so engineers can observe:

- Supply hold-up behaviour

- MCU brownouts

- Relay dropout/chatter

- Communication loss

- Illumination dimming (permitted)

- Delayed or unstable recovery - Wide-range input devices must be tested at both voltage extremes

If a product operates from, for example, 85–264 V AC, the test must be run:

- Once at the lowest rated input

- Again at the highest rated input

This often exposes weaknesses hidden at only one end of the range. - Real-world sags can last longer than the standard requires

EN 61000-4-11 specifies short-duration events, but real grid sags can last for minutes or longer. Many manufacturers voluntarily extend test duration to uncover intermittent failures not triggered by the standard’s timing. - Manual testing is allowed, but automation ensures accuracy

A Variac and a stopwatch meet the basic requirement, but it introduces:

- Inconsistent timing

- Unpredictable ramp rates

- Inaccurate zero-cross switching

Automated generators like the Haefely DIP 116 eliminate these variables, ensuring perfect repeatability and full compliance.

EN 61000-4-11 test equipment - supplied by APC Technology Group

Haefely DIP 116

Designed as an accessory for the AXOS series, the DIP 116 complies with IEC/EN 61000-4-11.

Key features:

- Max. input voltage on L-N: 264 VAC @ 50/60 Hz

- Max. input current : 16 A AC continuous (100%)

- Interrupt dip levels: ( 0%, 40%, 70%, 80% ) of Vin

- Automatic control

Available in a bundle!

Everything you require for Voltage & dip testing in a bundle.

Get it right the first time – bring voltage dip testing in-house

EN 61000-4-11 is more than just another EMC test method; it is a fundamental part of designing and validating resilient equipment. Whether you’re constructing EV infrastructure or UPS systems for data centres, understanding how your device reacts to grid disturbances is essential.

That’s why automated systems like the Haefely DIP 116 and AXOS platforms generate compliant waveforms, apply each disturbance with exact timing and provide complete reporting, all essential for reliable in-house pre-compliance testing and reducing the risk of costly failures.

APC supplies complete EN 61000-4-11 setups, demonstrations and specialist support at a price far lower than most teams expect.

|

One-time equipment cost |

|

|

Immediate testing, no scheduling |

|

|

Test immediately after every design change |

|

|

Real-time, unlimited |

|

|

Controlled and repeatable |

|

|

Development, troubleshooting and pre-compliance |

Get expert advice

Request a callback from a member of our technical team to get dedicated one-to-one consultancy for Radiated Emissions Testing, in-house capability and compliance.

Ready to bring EMC testing in-house?

Whether you're starting from scratch or upgrading an existing test area, APC supplies the full ecosystem of equipment you need to run compliant EMC testing in-house.

From bespoke test chambers to test and measurement equipment and RF systems, APC work with customers directly to reduce outsourcing costs, shorten development cycles and gain full control over pre-compliance testing.

Your partner for reliable and compliant EMC testing solutions

With 40+ years supporting the electronics industry, APC provides high-reliability components, test equipment and engineering support for organisations building or expanding their EMC and test capabilities. As an authorised distributor for 100+ specialist manufacturers, we supply genuine, traceable equipment backed by recognised certifications.

Resources for 61000-4-11 Voltage Dip Testing

Current edition: EN/IEC 61000-4-11:2020

Voltage Dip Testing Frequently Asked Questions (FAQ)

Which EMC Standard is used for Voltage Drop Testing?

EN/IEC 61000-4-11 is an EMC standard from the International Electrotechnical Commission defining test methods, procedures and limits for voltage dips, short interruptions and voltage variations in AC-powered electrical and electronic equipment. It applies to equipment rated up to 16 A per phase operating at 50–60 Hz.

What Equipment is used for Voltage Drop Testing?

- AC source

- Dip/interruption generator

- Monitoring equipment for voltage and current

- Ground reference plane

- Proper cable routing and loading conditions