Electrical Fast Transient (EFT) Burst Testing for EMC Immunity

Pulse waveforms, coupling methods and test setup for transient immunity compliance

Electrical fast transient (EFT) is a crucial EMC immunity test, considered one of the most effective methods for identifying potential operational issues within an in-house system.

EFT testing exposes a product to short, high-frequency 5 ns bursts that simulate the type of interference generated by relay contact bounce, inductive load switching and the electrical noise commonly found in industrial power networks.

If you’ve ever seen a device mysteriously reboot, drop a data packet or flicker for half a second whenever a nearby motor kicks in, you’ve already experienced the symptoms this test is designed to uncover.

EN 61000-4-4 defines the method for evaluating a device’s ability to withstand those fast transients. Building capability to run this test internally gives your engineering team an advantage with quicker debugging, fewer certification failures and far less downtime waiting on external labs.

In this guide, we will explain how EFT tests function, the necessary equipment and key considerations for engineers. It offers guidance for teams developing an in-house EFT test bench or EMC setup, as well as for businesses building or upgrading their own laboratory facilities.

What is EFT testing?

EFT (Electrical Fast Transient) testing is a conducted immunity test that assesses an electronic device's ability to withstand rapid, high-frequency voltage spikes and bursts. These disturbances, also known as Electromagnetic Interferences (EMI), are caused by events like switching inductive loads such as relays or motors and are simulated during the test to ensure the equipment operates reliably and does not malfunction or fail.

The testing is conducted in accordance with standards such as EN 61000-4-4 and is vital for industries including consumer electronics, automotive, medical and industrial equipment.

Where do they occur?

Real-world sources of EFT/Burst events include many everyday electrical scenarios. These electromagnetic interferences can occur across a wide range of systems as relay contact, power mains and switching components often create arcing and fast electrical transients. They are commonly tested to and occur in:

- AC power mains

- Automotive DC electrical systems

- Ethernet and data lines

- Electrical systems and subsystems

Each electromagnetic (EM) environment changes how these transients form and how they are defined. For example, automotive DC systems typically generate lower-voltage EFT events, often referred to as microbursts. As the electronics system or application changes, the characteristics of the transient and the way it is tested also change. These bursts can couple into nearby power, data and signal lines, causing connected electronic equipment to malfunction, reset or corrupt data.

These are not rare events; they occur continuously in most powered systems.

EFT testing ensures your product remains stable, even when installed in noisy, real-world environments.

Did you know?

Teams that build an in-house EFT bench can reproduce these disturbances on demand and identify which switching events cause resets, dropouts or communication instability long before products reach the field.

The Standard: EN 61000-4-4

EN 61000-4-4 is part of the wider IEC 61000 series that governs immunity testing. It describes the waveform characteristics, test setups, port types and pass criteria for EFT immunity.

The IEC version has been in compliance with EN 61000-4-4 and the Electromagnetic Compatibility (EMC) Directive. The most recent version of this standard is the 2012 version and the International Electrotechnical Commission (IEC) offers a revised version for comparing changes.

EFT test levels

The standard requires equipment to be tested through:

- Power ports (AC or DC supply lines)

- Signal, data, and control ports

- Protective earth ports

The table below lists the test levels and their corresponding line types. The associated test levels, 1-4 are defined by the standard and should be referenced accordingly.

EN 61000-4-4 Stress Levels |

||||

|

Power Supply Port |

I/O, Signal, Data & Control Lines |

|||

|

Level |

Peak Voltage (kV) |

Current (A) |

Peak Voltage (kV) |

Current (A) |

|

1 |

0.5 |

10 |

0.25 |

5 |

|

2 |

2 |

20 |

0.5 |

10 |

|

3 |

3 |

40 |

1 |

20 |

|

4 |

4 |

80 |

2 |

40 |

|

X |

Special |

Special |

Special |

Special |

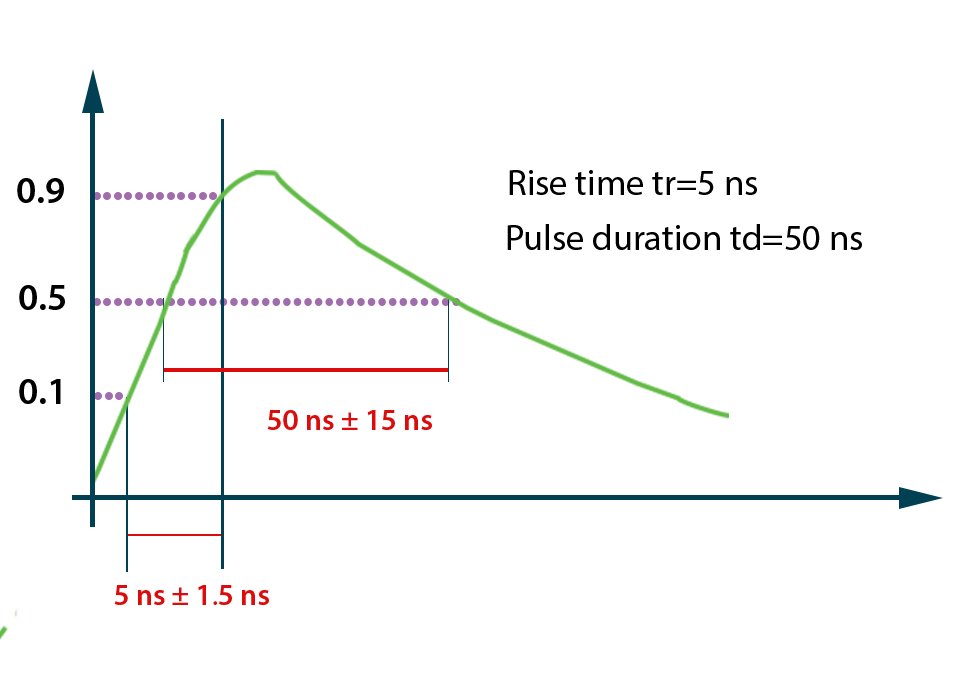

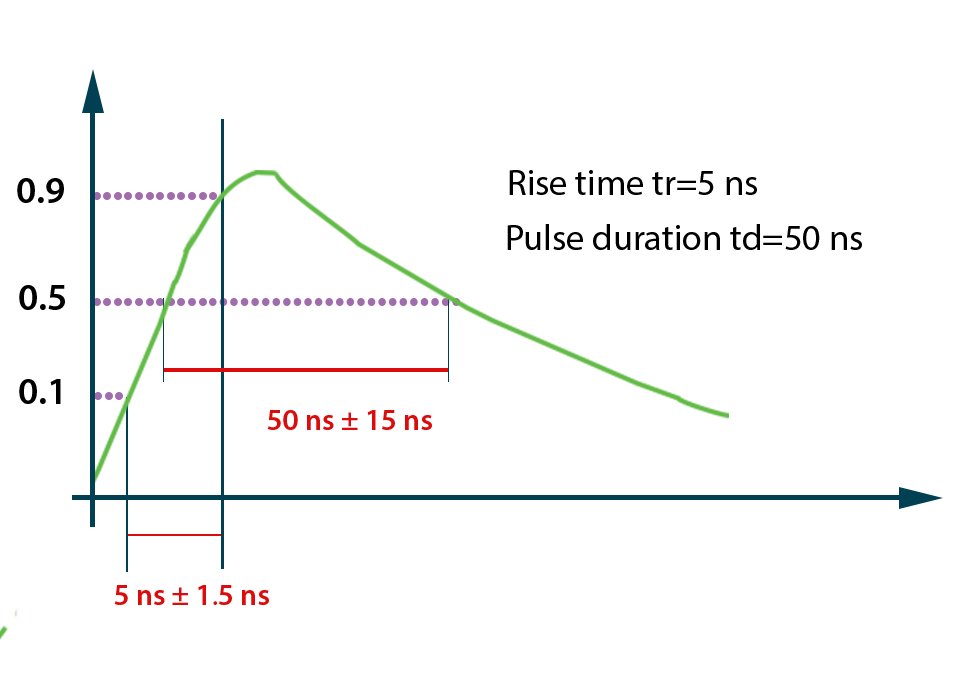

What is the EFT Burst Waveform?

The EFT (Electrical Fast Transient) burst waveform tests an electronic device’s immunity to fast electrical noise. It uses rapid pulses (~5 ns rise, ~50 ns width) repeated in bursts every ~300 ms to mimic switching transients in power and control systems.

EFT burst waveform

Key waveform parameters include:

- Rise time: ~5 ns

- Pulse width: ~50 ns

- Burst frequency: typically, 5 kHz or 100 kHz

- Burst duration: 15 ms

- Burst repetition: 300 ms

- Amplitude: up to several kilovolts depending on the test level

These values ensure the test realistically simulates the transient disturbances generated in industrial settings.

What the EFT waveform tells you about susceptibility

EFT bursts are harsh on designs because their rapid rise time can stimulate parasitic capacitances, PCB trace inductances, enclosure seams and cable shielding vulnerabilities.

A surge pulse can often be handled by power-entry designs alone. Still, EFT routinely reveals problems deep inside a system, ground strategy, firmware handling, connector shielding and even board-level layout.

This is why many engineers diagnose their earliest system failures using EN 61000-4-4 before they go near a test house. In-house capability helps teams catch issues when they’re easiest and cheapest to solve.

You only get one chance at a first-time pass

Investing in the equipment required for an in-house EFT setup is much more affordable than teams anticipate

At APC, we understand the most common failure modes, the pressure to achieve a first-time pass and the real cost of delays. Our EMC specialists work directly with design engineers to help you stay on schedule and reach the test house with confidence.

Speak to one of our EMC experts today to discuss your test requirements, troubleshoot design issues or arrange a demonstration of our equipment.

0330 313 3220 | [email protected]

How is EFT testing conducted to the EN 61000-4-4 Standard?

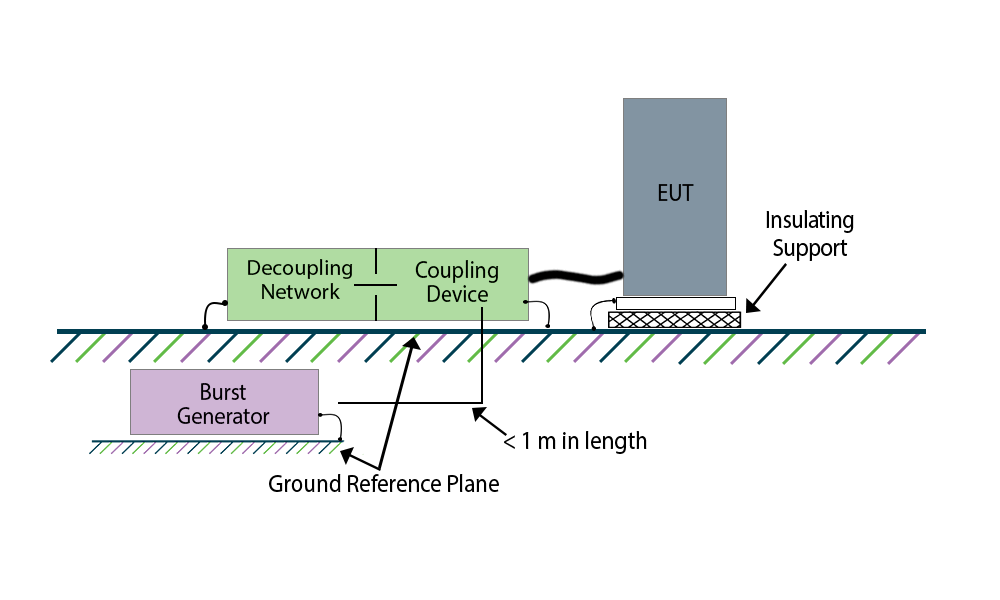

EFT subjects an Equipment Under Test (EUT) to controlled bursts of nanosecond-scale pulses, as outlined in EN 61000-4-4. The purpose of this test is to recreate fast and high-frequency disturbances caused by switching events such as relay bounce or contact arcing in a repeatable laboratory environment.

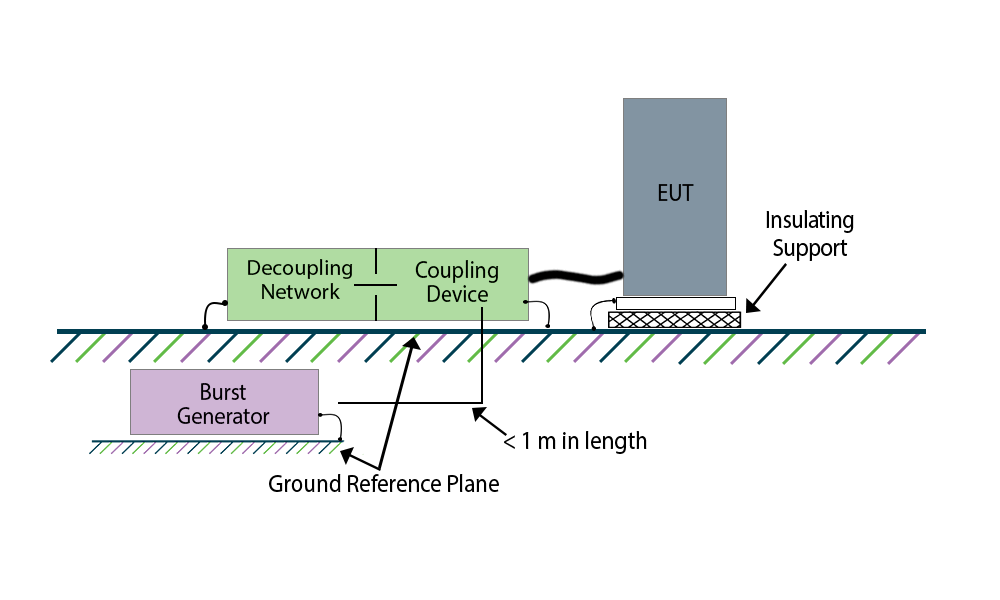

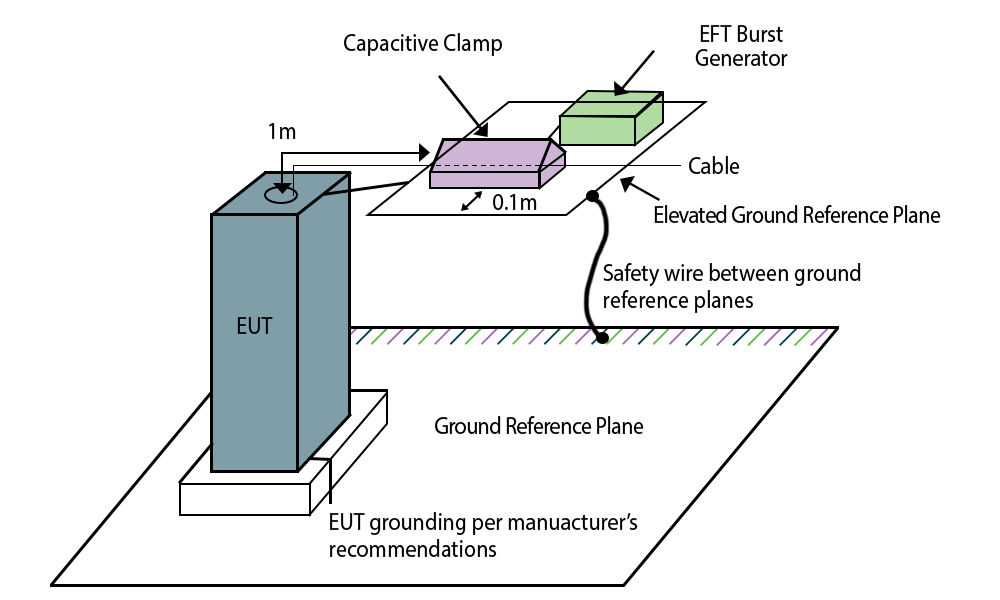

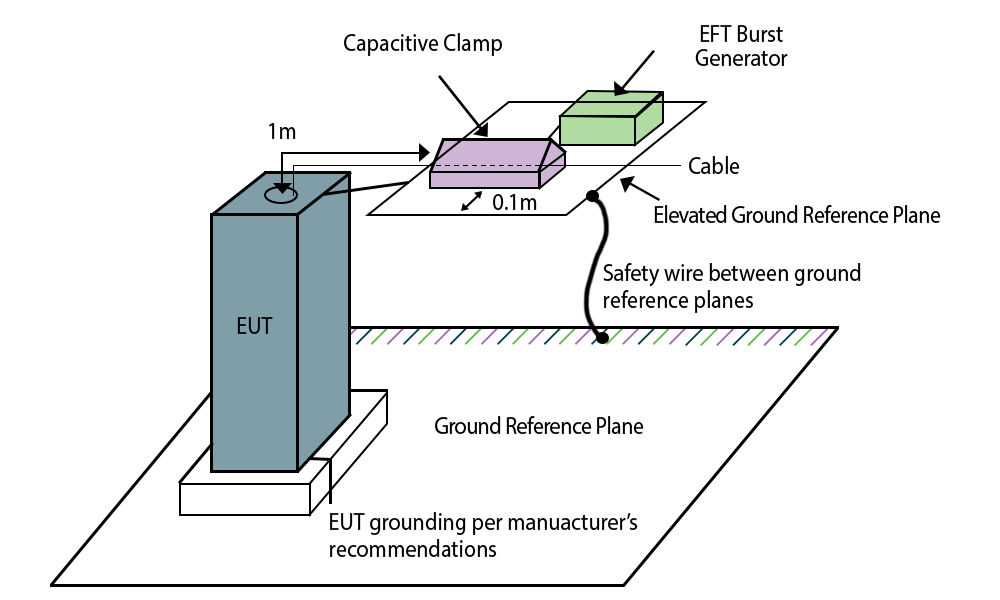

The test setup comprises an EFT burst generator, a coupling/decoupling network (CDN) and capacitive coupling clamps. These devices introduce rapid transients onto the EUT’s power and signal lines while the equipment rests on a grounded reference plane.

To ensure consistent coupling conditions, both the EUT and test hardware must be placed on a non-conductive surface, positioned at least 0.5 m from other conductive objects, with no more than 1 m of cable between the coupling device and the EUT.

EN 61000-4-4 defines two completely different injection methods, depending on which type of port you are testing:

- Power-Line Injection (via CDN) - for AC/DC mains or DC supply inputs.

- Signal/Data Line Injection (via Capacitive Clamp) - for ANY non-power cable, including I/O, communications, sensor lines and control wiring.

Both are part of the same EFT test, but they stress the device in very different ways and reveal different types of failures.

An Electrical Fast Transient (EFT) generator can apply bursts using two primary methods for conducted immunity testing.

What are the two primary methods an EFT generator can apply bursts?

1. Power-line injection (via CDN) ‘standard method’

The Coupling/Decoupling Network (CDN) couples the burst directly onto the AC or DC supply conductors. This method stresses the EUT’s power-entry design.

This method stresses:

- Input filtering

- Common-mode chokes

- Protective earth bonding

- Internal power distribution and local decoupling

Failures here typically appear as resets, watchdog triggers, temporary brownouts or short-lived loss of functionality.

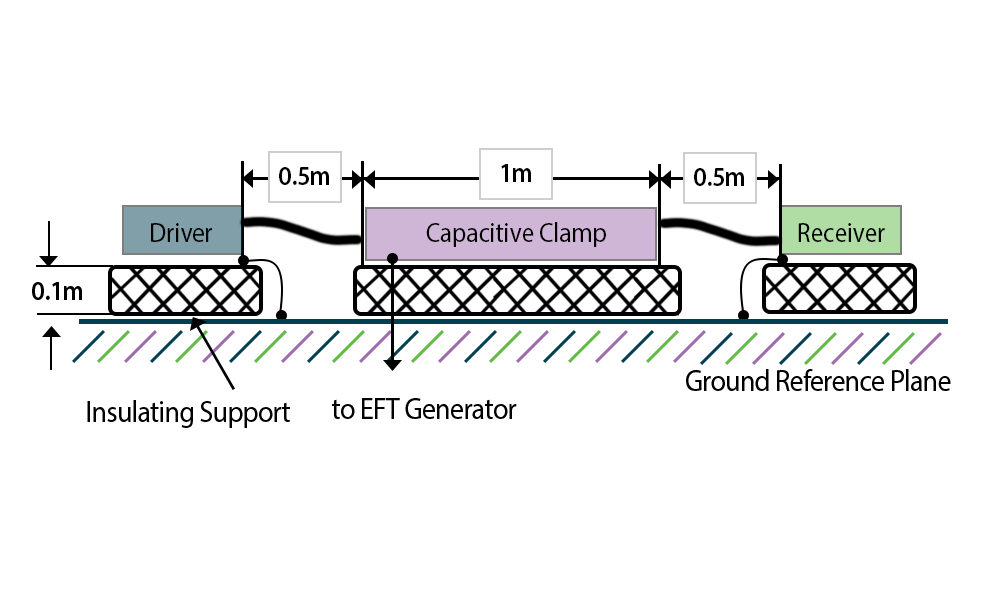

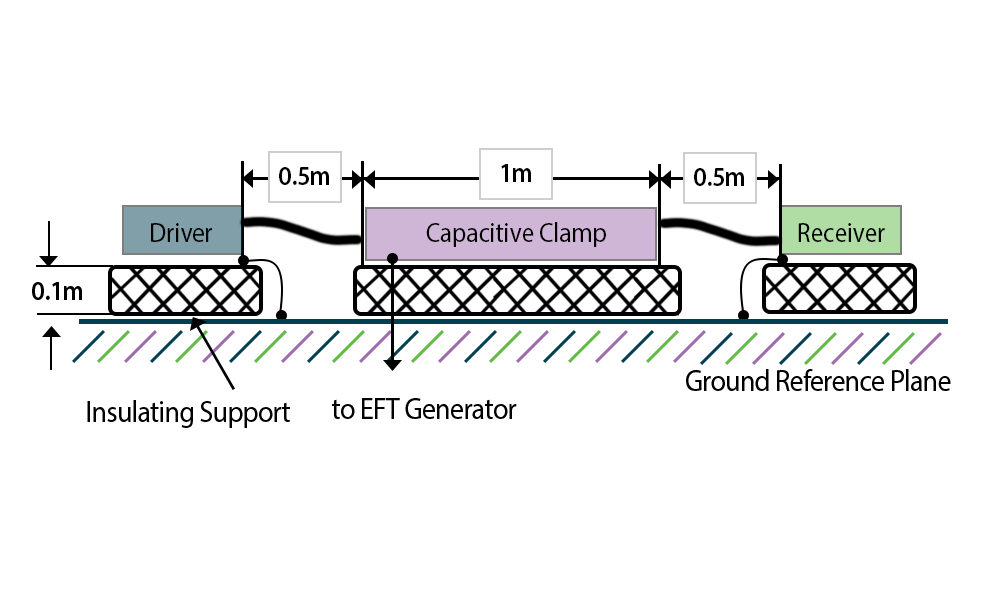

2. Signal & data cable testing (via Capacitive Coupling Clamp)

For I/O, communication or sensor lines, the burst is coupled via a Capacitive Coupling Clamp (CCL).

This method stresses:

- Shield integrity

- Ground reference continuity

- Cable geometry

- Interface-level immunity

Many devices pass CDN testing but fail under the clamp (CCL), which highlights grounding or shielding weaknesses rather than power-entry issues.

During the test, the EUT must function normally so that display behaviour, communication stability, timing and control outputs can be observed. Performance is categorised according to the standard’s criteria (A through D), providing manufacturers with a clear view of resilience and recovery behaviour.

Choosing the right EFT/Burst generator for your lab

Selecting EFT test equipment is a key decision for engineers building an in-house EMC capability. A compliant generator must meet the waveform requirements of EN 61000-4-4 and provide stable burst-repetition patterns under load.

Key features to look for:

- Adjustable output voltage to meet all test levels

- Support for 5 kHz and 100 kHz burst rates

- Integrated CDN for power port testing

- Compatible capacitive clamps for signal/data injection

- Clear test automation software (USB/Ethernet control if needed)

- Waveform verification capabilities

- Options for surge or combined immunity testing (if you want multi-function equipment)

Setting up an in-house lab for EN 61000-4-4 testing

EFT/Burst testing requires a defined set of instruments and accessories to deliver transients consistently and safely in compliance with EN 61000-4-4. Each component serves a specific role in generating, coupling and controlling the high-frequency bursts applied to the Equipment Under Test (EUT).

A typical in-house layout includes:

- A ground reference plane

- A burst generator

- A coupling/decoupling network (CDN) for power port testing

- A capacitive coupling clamp (CCL) for testing non-power ports

- An insulating support

- The equipment under test (EUT)

- Monitoring equipment or software to evaluate EUT performance

Power port injection occurs via the CDN, which couples bursts to the supply lines while protecting your generator from your EUT’s load. Signal lines and I/O cables are tested using a capacitive clamp, which induces bursts into the cable shield or conductor bundle.

Equipment required for EFT/Burst testing – supplied by APC Technology Group

AXOS5 Compact

Key features:

- Fully compliant with the standard requirements of IEC/EN61000-4-4, IEC/EN 61000-4-5 and IEC/EN 61000-4-12

- Impulse voltage capability of 5 kV specifically for EFT/Burst

- Supports line voltages up to 480 V AC/DC and a rated current of 32 A per phase (for three-phase mains systems)

- Combined CDN for Surge, Ring Wave and EFT/Burst - Handles multiple immunity test types, not limited to EFT

Coupling/Decoupling Network (CDN) - Power-line Injection

Key features:

-

Fully compliant with the standard requirements of IEC/EN61000-4-4, IEC/EN 61000-4-5 and IEC/EN 61000-4-12

-

Supports a maximum EFT/Burst input voltage of 5 kV

- Handles line voltages up to 480 V AC/DC and EUT current up to 32 A per phase, making it suitable for industrial-grade setups

Capacitive Coupling Clamp (CCL)

Key features:

- Designed as per IEC 61000-4-4 Edition 3

- EFT/Burst testing of signal and data lines

- For cable diameters from 4 – 40 mm

- Active coupling length 1 m

Available in a bundle!

All the equipment required for EFT/Burst testing in a bundle!

Troubleshooting EFT failures in design and in-house testing

Most EFT-related issues stem from grounding, cable routing, shielding or PCB layout. Internal design decisions often increase susceptibility long before reaching a test lab. For example:

- Long unshielded sensor cables act like EFT antennas

- Inconsistent ground scheme between PCB sections can cause latch-ups

- High-speed digital interfaces may glitch if no transient filtering is present

- Internal DC-DC converters can briefly drop out under burst load

Bring ESD Testing In-House with APC

Fast transient burst testing isn’t just another EMC checkbox, it is one of the most valuable in-house immunity tests for identifying real-world device vulnerabilities. EN 61000-4-4 tests your design precisely at the points where engineering decisions matter most in grounding, shielding, PCB layout, firmware stability and how effectively your device manages disturbances in industrial electrical environments.

By integrating this capability into your in-house lab, you empower your engineering team to troubleshoot early, confirm design changes swiftly and achieve certification targets with fewer surprises.

Cut outsourcing costs and test on your schedule. APC provides EN 61000-4-2 setups, equipment demos and specialist support.

Below are some examples of how APC can support you with your test setup and equipment requirements to fit your long-term testing needs.

|

One-time equipment cost |

|

|

Immediate testing, no scheduling |

|

|

Test immediately after every design change |

|

|

Real-time, unlimited |

|

|

Controlled and repeatable |

|

|

Development, troubleshooting and pre-compliance |

Get expert advice

Request a callback from a member of our technical team to get dedicated one-to-one consultancy for EFT Testing, in-house capability and compliance.

Ready to bring EMC testing in-house?

Whether you're starting from scratch or upgrading an existing test area, APC supplies the equipment you need to run an EMC testing in-house.

From bespoke test chambers to test and measurement equipment and RF systems, APC work with customers directly to reduce outsourcing costs, shorten development cycles and gain full control over pre-compliance testing.

Your partner for reliable and compliant EMC testing solutions

With 40+ years supporting the electronics industry, APC provides high-reliability components, test equipment and engineering support for organisations building or expanding their EMC and test capabilities. As an authorised distributor for 100+ specialist manufacturers, we supply genuine, traceable equipment backed by recognised certifications.

Resources for EN 61000-4-4 (EFT/Burst) - Electrical Fast Transient/Burst Immunity Testing

Current (3rd Edition): EN/IEC 61000-4-4:2012

Previous (2nd Edition): EN/IEC 61000-4-4:2004

Fast Transient Burst (EFT) Testing – Frequently Asked Questions (FAQ)

Why is EFT/Burst testing important for EMC compliance?

EFT testing is critical because fast switching transients can cause resets, data corruption, communication failures or unstable behaviour. IEC/EN 61000-4-4 compliance demonstrates that a product can operate reliably in electrically noisy environments without malfunctioning.

What causes EFT or burst disturbances in real-world applications?

EFT bursts are typically generated by relay contact bounce, motor start/stop events, solenoid switching, contactors and power supply switching. These disturbances propagate along power lines, earth paths and signal cables, coupling into sensitive electronics.

What standards apply to EFT/Burst testing?

Fast Transient Burst testing is defined by IEC/EN 61000-4-4, which specifies the test waveform, burst repetition rate, coupling methods, test levels and performance criteria. It forms part of the IEC 61000 immunity standards series.

What voltage levels are used in EFT testing?

IEC/EN 61000-4-4 defines typical test levels of 0.5 kV, 1 kV, 2 kV and 4 kV for power lines, and 0.25 kV to 2 kV for signal and I/O lines using a capacitive clamp. The required level depends on the product category and intended environment.

What is the difference between EFT testing and surge testing?

EFT testing focuses on fast, low-energy, repetitive transients caused by switching events, while surge testing evaluates high-energy disturbances such as lightning and power system surges. Both tests assess immunity but simulate different real-world electrical phenomena.

What are common failure modes seen during EFT testing?

Common EFT-related failures include microcontroller resets, software lockups, communication dropouts, corrupted data, unintended output switching and intermittent behaviour that may only appear under repetitive transient stress.

Can EFT/Burst testing be done in-house?

Yes. Many manufacturers perform EFT pre-compliance testing in-house to identify design weaknesses early, reduce external test lab costs and accelerate development. An in-house setup typically includes an EFT generator, CDNs, capacitive clamps and a properly grounded test bench. Contact our team today for more information on APC’s EMC consultancy services.

What is the burst repetition rate in EFT testing?

IEC/EN 61000-4-4 specifies burst repetition rates of 5 kHz and 100 kHz, depending on the test level and equipment category. Higher repetition rates apply greater stress to digital and power circuits.

What performance criteria apply during EFT testing?

The standard defines performance criteria A, B and C, which specify whether the equipment must operate normally during the test or whether temporary degradation is allowed, provided full recovery occurs after the test.