Surge Immunity Testing for Lightning and Switching Transients

Combination wave requirements, coupling methods and test setups for high-energy overvoltage protection

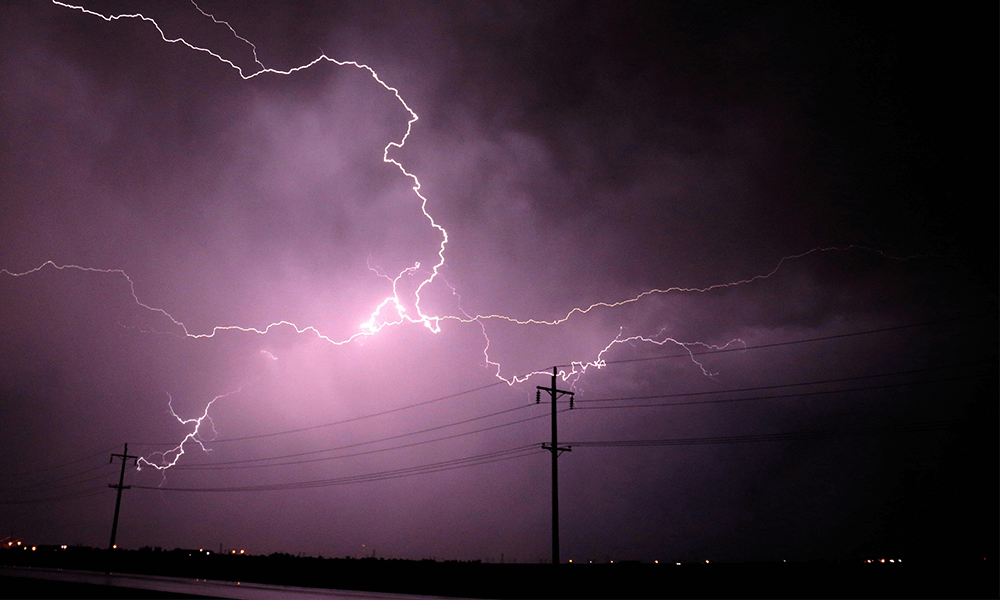

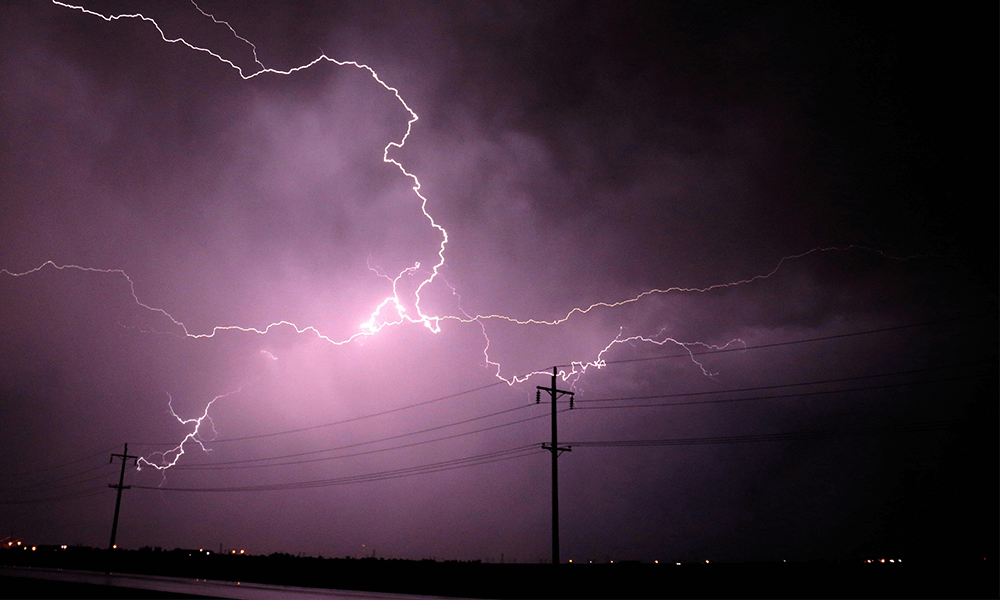

Surge immunity testing evaluates how your product responds when exposed to high-energy transients, such as those caused by lightning and switching events.

Within an EMC test strategy, surge testing is one of the most destructive tests an electronic system will face, and passing it requires a strong combination of design, grounding, protection components and enclosure strategy.

What is surge testing?

Surge testing refers to immunity testing for electrical equipment against surges, as defined by the EN 61000-4-5 standard. This involves using a surge generator to apply a standardised voltage and current waveform (the "1.2/50-8/20 μs" impulse is common) to simulate events like lightning strikes or power system switching. The test levels are classified by severity, and the equipment's performance is evaluated based on pre-defined criteria, which range from working perfectly to failing the test.

Real-world examples of surge events

Real events that EN 61000-4-5 surges simulate:

- Lightning strikes near overhead lines

- Switching of large inductive loads

- Power system faults and clearing

- Long cable runs exposed to outdoor environments

- Inrush and switching of capacitor banks

- Utility grid disturbances and transformer switching

This is why surge testing is mandatory for systems connected to long cables, outdoor systems, industrial equipment or critical control systems.

What surge testing is not

To avoid confusion with other types of fast, high-frequency testing within EMC, the following is not related to surge testing.

- It is not an ESD test (that’s IEC 61000-4-2)

- It is not an EFT/Burst test (that’s IEC 61000-4-4)

- It is not a lightning direct strike

- It does not replace proper surge protection device ratings

- It does not test radiated disturbance

Surges contain far more energy than EFT/Burst or ESD. While EFT tests fast, high-frequency disturbances, a surge imitates the slow, high-energy events that can damage components, break insulation and cause catastrophic failures.

What is the purpose of surge testing?

Surge testing verifies that your product can tolerate real-world overvoltage events without:

- Permanent damage

- Insulation breakdown

- Fire risk

- System shutdown

- Unsafe behaviour

Surge testing allows engineers to uncover hidden design weaknesses early, especially in areas like input protection (MOVs, TVS, GDTs), PCB creepage and clearance and common-mode grounding. By identifying these issues before the product reaches the field, surge testing helps protect end-users and ensures the device operates reliably in the environments it’s designed for.

Performance criteria (A, B, C, D)

- Criterion A: EUT must operate normally during and after the test

- Criterion B: Temporary degradation is allowed, but the system must self-recover

- Criterion C: Temporary loss of function is allowed but requires manual intervention to recover

- Criterion D: Permanent damage or unsafe behaviour

Industries where surge testing is crucial

EV Charging Infrastructure

& Power Electronics

EV chargers and fast-charging systems must withstand grid and lightning-induced surges travelling through long outdoor cables. Strong surge immunity prevents PSU failures, controller lockups and unsafe charging behaviour (EN 61851-21-2).

Energy, Utility &

Grid-Connected Equipment

Smart meters, relays, inverters and substation controllers operate in surge-heavy environments created by grid switching and lightning activity. Surge immunity avoids false trips, shutdowns and system instability (EN 61000-6-2 / EN 61000-4-5).

Laboratory, Test &

Measurement Instruments

Precision instruments, oscilloscopes and DAQs depend on surge immunity to prevent corrupted readings, unexpected resets or PSU damage when connected to noisy industrial mains or high-energy setups (EN 61326-1).

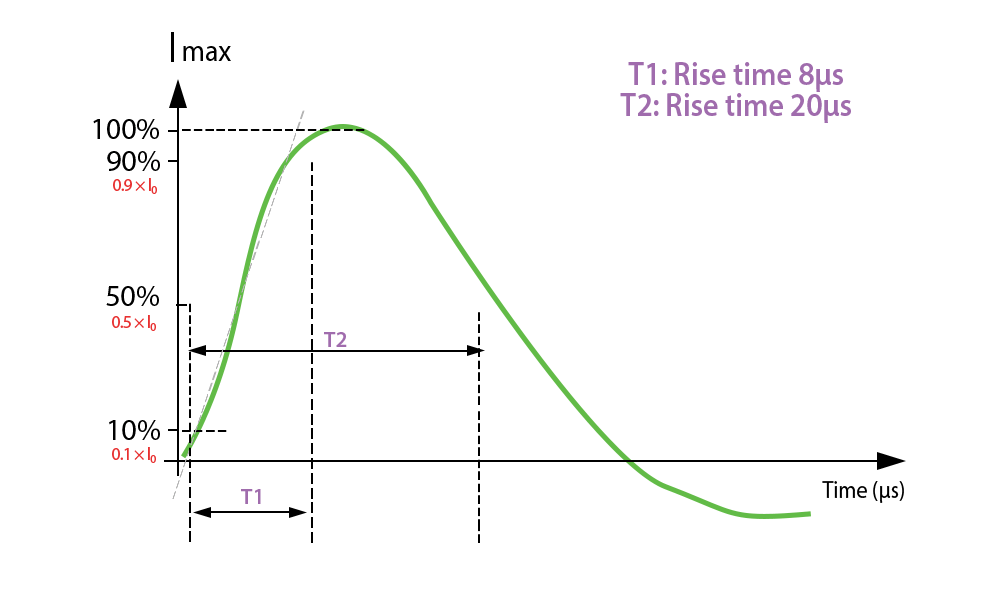

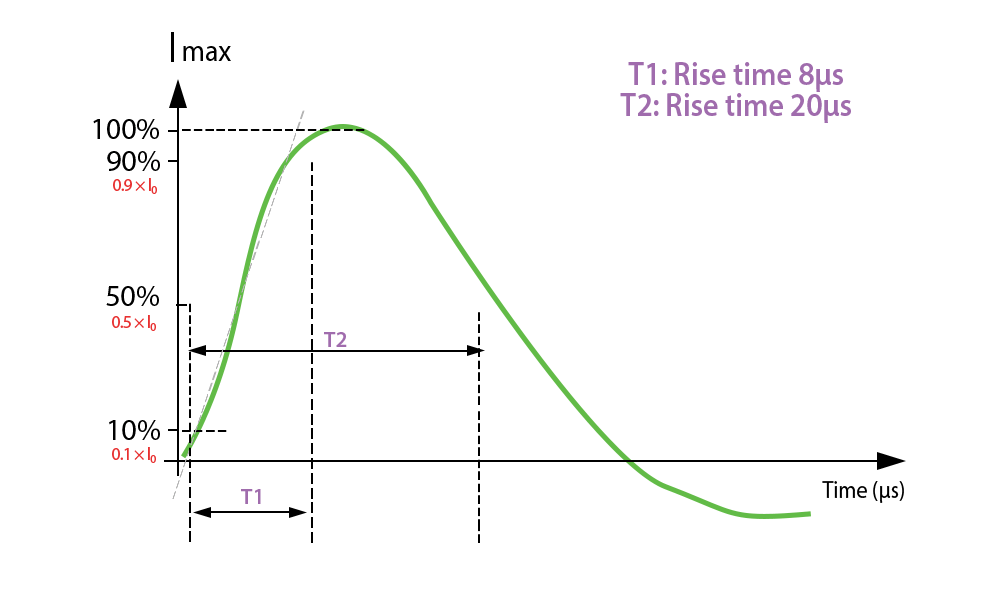

Understanding the surge waveform (1.2/50 µs & 8/20 µs)

The EN surge waveform consists of two parts:

1. Voltage waveform - 1.2/50 µs

- 1.2 µs (Front Time): This is the time it takes for the voltage to rise from zero to its peak value, simulating the steep front of a lightning surge

- 50 µs: (Time to ‘Half/Tail Time’): This is the time it takes for the voltage to decay from its peak value to 50% of that value, representing the dissipation of the energy from the strike

This is applied to the power port to simulate overvoltage conditions entering the device. The 1.2/50 µs waveform is a global standard that ensures electrical equipment can withstand the stress of a lightning strike.

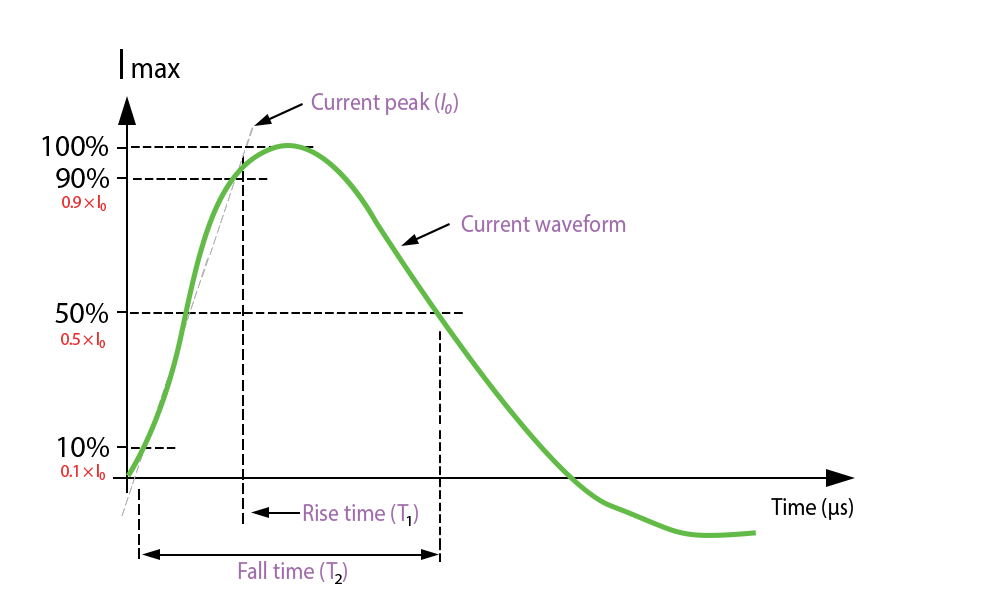

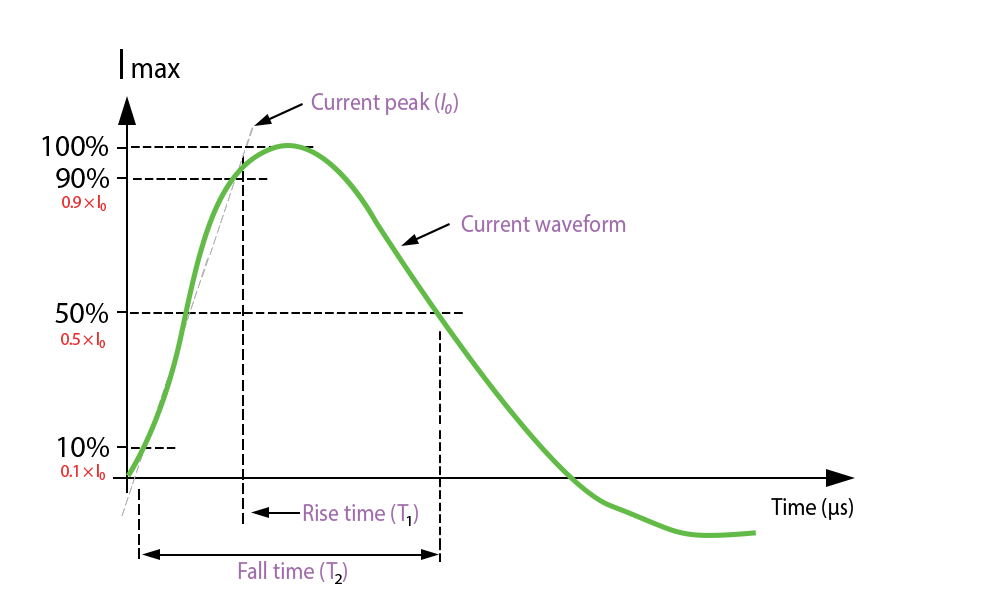

2. Current waveform - 8/20 µs

- 8 µs (Front Time): The time it takes for the current to go from 10% to 90% of its peak amplitude, which is 8 microseconds (8 µs)

- 20 µs (Time to ‘Half/Tail Time’): The time it takes for the current to decay to 50% of its peak value at 20 microseconds (20 µs)

The 8/20 µs waveform is used to test the resilience of surge protective devices against lightning-induced surges that are not a direct strike, like those induced on conductors.

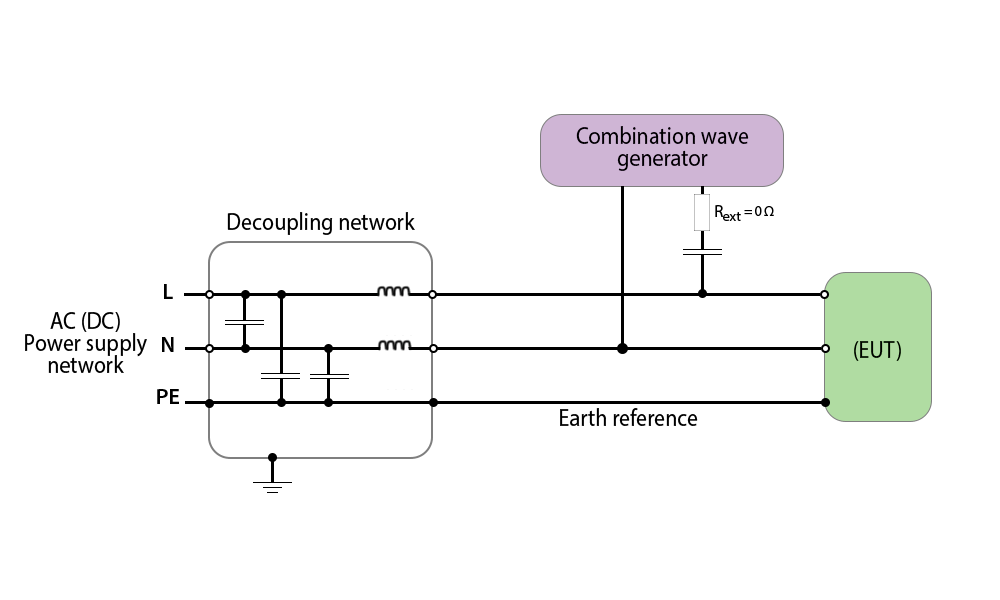

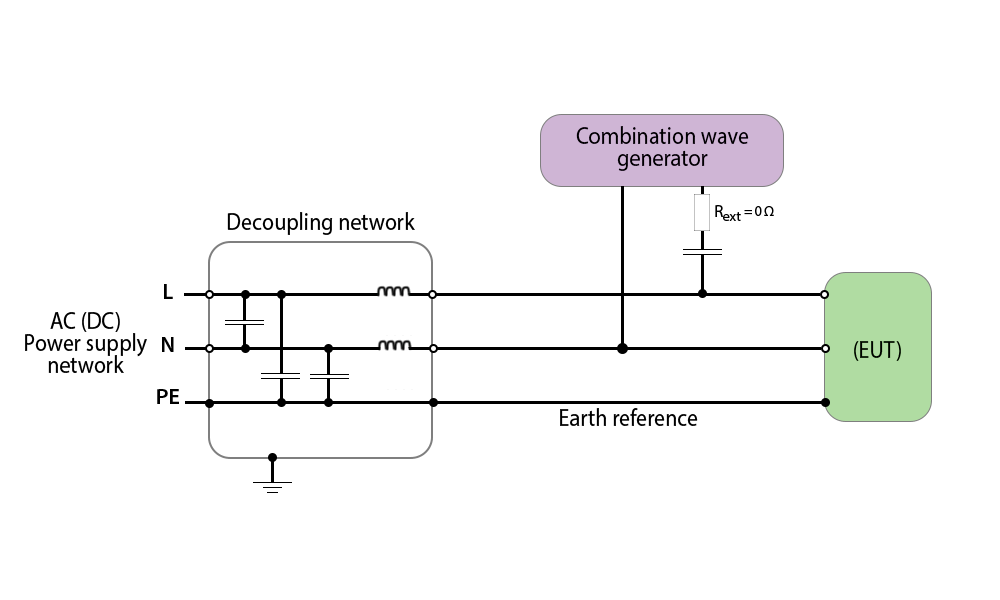

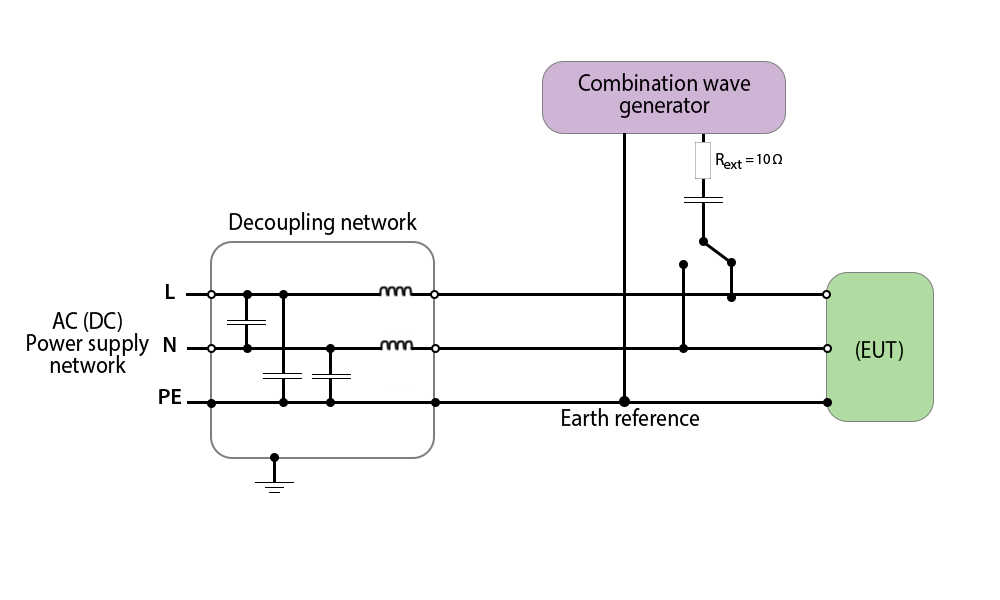

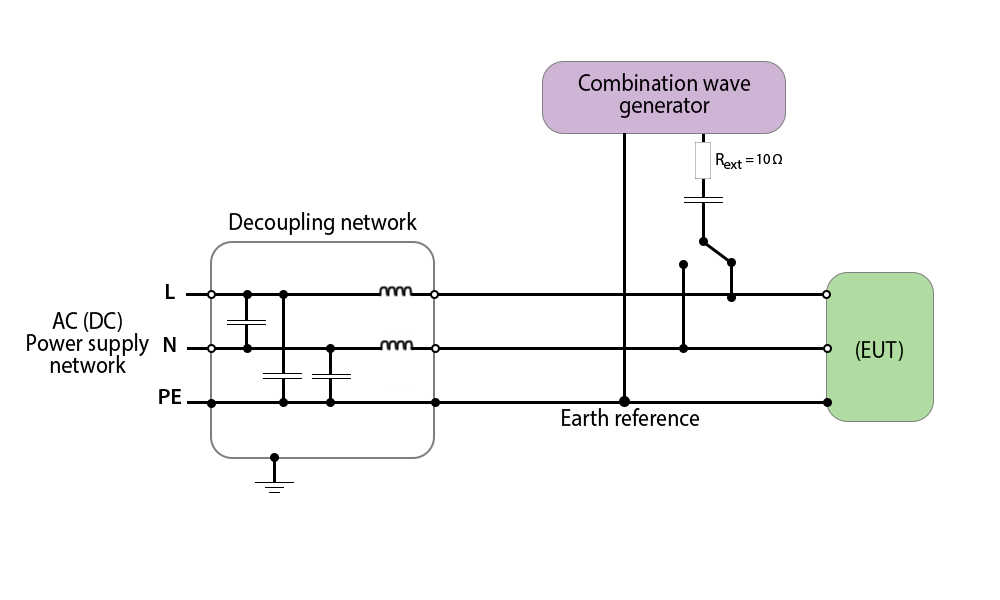

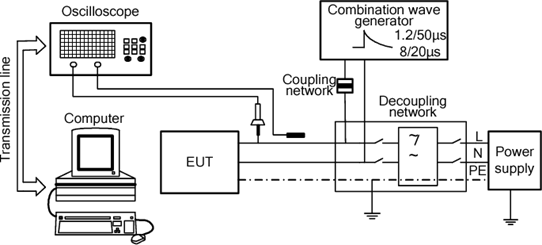

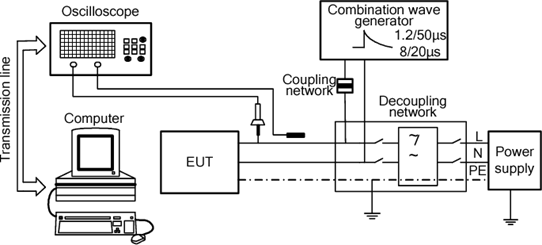

Surge coupling methods: line-to-line vs line-to-earth

EN 61000-4-5 uses two coupling methods because real surge events inject energy into equipment in different ways.

Line-to-line (L-L): Represents a differential-mode surge that travels between active conductors and stresses the power-input components, filters and rectifiers.

Line-to-earth (L-PE): Simulates a common-mode surge driven toward ground during lightning or grid disturbances; these surges are typically higher in amplitude and expose weaknesses in insulation, shielding, grounding and enclosure bonding.

L-PE surges are typically higher in amplitude.

Testing both of these modes ensures the device can survive the full range of high-energy overvoltages found in residential, commercial and industrial environments, improving product safety and reducing field failure risks.

Example voltage levels

Example surge test voltages differ depending on application and standard, but a typical range for lower voltage AC power is up to 4 kv. Standards like EN 61000-4-5 specify test levels such as 0.5 kV, 1 kV, 2 kV and 4 kv.

|

Installation Class |

Test Voltage |

Typical Environment |

|

Class 0 |

No surge |

SELV systems |

|

Class 1 |

0.5 kV |

Protected circuits |

|

Class 2 |

1 kV |

Residential/Commercial |

|

Class 3 |

2 kV |

Industrial |

|

Class 3 |

4 kV |

Harsh industrial/outdoor |

However, for testing electrical machinery, a common formula might recommend a test voltage of 2× Unom + 1000 V, which results in a 1.8 kV test for a 400 V motor. High-voltage applications require much higher, specific voltages as outlined by standards like ANSI/EASA and IEEE.

Surge immunity test setup (EN 61000-4-5)

A compliant setup includes:

- 10 cm insulating support above the ground plane

- CDN connected to power port

- Surge generator connected to CDN

- Cables arranged with specified height and length

- Grounding straps connecting CDN/GEN to the plane

- EUT configured in full operational mode

Test equipment required for surge testing - supplied by APC Technology Group

AXOS-8 Compact

Best for: In-house labs needing a flexible immunity platform covering surge, EFT, dips & interrupts; single-phase or moderate-load applications.

- Surge wave output (voltage) up to 5 kV, combination wave (1.2/50 µs + 8/20 µs) at power line CDN

- Surge wave current output (8/20 µs) up to 2.5 kA in surge mode

- Integral coupling network integrated single-phase CDN (up to ~16 A) included

VTM 15000 (Impulse Transformer)

Best for: Specialised applications where higher-voltage impulse or isolation testing is required (e.g. insulation breakdown testing, high-voltage modules).

- Doubles generator voltage up to 10 kV when paired with AXOS-5, or higher when paired with other generators. Primary role is isolation testing with 1.2/50 µs shape

- Current waveform not defined (focus is voltage impulse for insulation); output impedance selectable 12 Ω / 40 Ω / 500 Ω

- 1.2/50 µs voltage impulse for insulation tests (e.g., IEC 60060-1, IEC 61180-1)

Available in a bundle!

Everything you require for surge testing in a bundle.

You only get one chance at a first-time pass.

Surge immunity failures are some of the most costly and time-consuming issues to fix and often occur late in development when redesigns are the most challenging. By bringing IEC 61000-4-5 surge testing in-house, your engineering team can identify weaknesses early, verify fixes quickly and avoid the costly cycle of failed test-house visits.

High-energy surge events reveal real design vulnerabilities in protection networks, grounding, insulation and PCB layout. When you can test these conditions internally, you gain complete control over debugging, scheduling and certification readiness.

APC provides fully compliant in-house surge setups, expert guidance and equipment demonstrations, helping you build a reliable, safe and cost-effective immunity test bench that keeps your project on track.

|

One-time equipment cost |

|

|

Immediate testing, no scheduling |

|

|

Test immediately after every design change |

|

|

Real-time, unlimited |

|

|

Controlled and repeatable |

|

|

Development, troubleshooting and pre-compliance |

Bring surge immunity testing in-house with APC

You only get one chance at a first-time pass. Surge immunity failures are among the most costly and time-consuming issues to fix and often occur late in development, when redesigns are the most challenging. By bringing IEC 61000-4-5 surge testing in-house, your engineering team can identify weaknesses early, verify fixes quickly and avoid the costly cycle of failed test-house visits.

High-energy surge events reveal real design vulnerabilities in protection networks, grounding, insulation and PCB layout. When you can test these conditions internally, you gain complete control over debugging, scheduling and certification readiness.

APC provides surge test setups, expert guidance and equipment demonstrations, helping you build a reliable, safe and cost-effective immunity test bench that keeps your project on track.

Below are some examples of how APC can support you with your test setup and equipment requirements to fit your long-term testing needs.

|

One-time equipment cost |

|

|

Immediate testing, no scheduling |

|

|

Test immediately after every design change |

|

|

Real-time, unlimited |

|

|

Controlled and repeatable |

|

|

Development, troubleshooting and pre-compliance |

Get expert advice

Request a callback from a member of our technical team to get dedicated one-to-one consultancy for Surge Testing, in-house capability and compliance.

Ready to bring EMC testing in-house?

Whether you're starting from scratch or upgrading an existing test area, APC supplies the equipment you need to run EMC testing in-house.

From bespoke test chambers to test and measurement equipment and RF systems, APC work with customers directly to reduce outsourcing costs, shorten development cycles and gain full control over pre-compliance testing.

Your partner for reliable and compliant EMC testing solutions

With 40+ years of expertise supporting the electronics industry, APC provides high-reliability components, test equipment and engineering support for organisations building or expanding their EMC and test capabilities. As an authorised distributor for 100+ specialist manufacturers, we supply genuine, traceable equipment backed by recognised certifications.

Resources for EN 61000-4-4 (EFT/Burst) - Electrical Fast Transient/Burst Immunity Testing

Current: EN/IEC 61000-4-5:2014

References:

Figure 1: Surge Immunity Test Setup (EN 61000-4-5) Diagram emcdirectory.com

Surge Testing (EN/IEC 61000-4-5) – Frequently Asked Questions (FAQ)

When should surge testing be performed during product development?

Surge testing should be performed during the design validation and pre-compliance stages, before final certification. Early testing allows engineers to identify weaknesses in power input protection, grounding and isolation before costly redesigns or external lab failures occur.

Which products typically require surge testing to EN 61000-4-5?

Products connected to AC mains, external DC power supplies or long cable runs commonly require surge testing. This includes industrial equipment, power supplies, control systems, communication devices and infrastructure-connected electronics.

What is the difference between line-to-line and line-to-earth surge testing?

Line-to-line testing applies surges between conductors (e.g. live to neutral), while line-to-earth testing applies surges between a conductor and protective earth. Line-to-earth tests are often more severe and reveal weaknesses in insulation, grounding and protection components.

How do I know which surge test level applies to my product?

The required surge level depends on the product’s installation environment, overvoltage category and applicable product standard. Equipment installed in fixed or outdoor environments typically requires higher surge levels than portable or internally powered devices.

What design changes are commonly needed after a surge test failure?

Common mitigations include adding or upgrading MOVs, TVS diodes, gas discharge tubes, improving grounding paths, increasing creepage and clearance distances or redesigning power input filtering. Surge failures often require hardware-level changes rather than firmware fixes.

Can surge testing damage the equipment under test?

Yes. Surge testing involves applying high-energy pulses that can permanently damage components if adequate protection is not in place. This is why pre-compliance testing is recommended, allowing destructive failures to occur before formal certification or customer deployment.

How many surge pulses are applied during testing?

EN/IEC 61000-4-5 typically requires multiple positive and negative surge pulses to be applied at each test point, with defined intervals between pulses. This ensures repeatability and exposes cumulative stress effects on protection circuitry.

What is the role of coupling/decoupling networks (CDNs) in surge testing?

CDNs inject surge energy into specific lines while preventing the surge from propagating back into the mains supply or auxiliary equipment. Correct CDN selection is critical for achieving compliant and repeatable surge test results.