Conducted Emissions Testing for EMC Compliance

LISN setup, measurement methods and pass/fail limits for mains-borne interference

Conducted emissions testing is a core part of EMC compliance. Unlike radiated emissions that travel through the air, conducted emissions travel along cables i.e. power leads, signal lines (anything physically connected to your product). If your device plugs into the mains or connects to other equipment, you'll need to pass conducted emissions testing.

In this guide, we'll explore what conducted emissions are, why they matter for product compliance, how they're measured using Line Impedance Stabilisation Networks (LISNs) and the requirements defined in EN 55032 (CISPR 32) and the methodology according to CISPR 16.

What are conducted emissions?

Conducted emissions are unwanted electrical noises that travel along the cables connected to your product. This noise can spread to other equipment on the same circuit, so if your power supply is generating interference, it can affect anything else plugged into the same mains supply.

Testing covers the frequency range from 150 kHz to 30 MHz. Below 150 kHz, generally these line frequency harmonic emissions are treated differently than EMI and considered normal power system behaviour.

Anything above 30 MHz, cables start acting as antennas and radiated emissions becomes the test method.

Where do conducted emissions come from?

Almost every modern electronic device generates some level of conducted emissions.

Common contributors include:

- Switched-mode power supplies (SMPS) operating at frequencies from tens of kHz to several MHz

- DC-DC converters and voltage regulators

- Digital clock oscillators and high-speed data buses

- Motor drives and inverters

- LED drivers with PWM dimming

- Thyristor and triac-based controllers

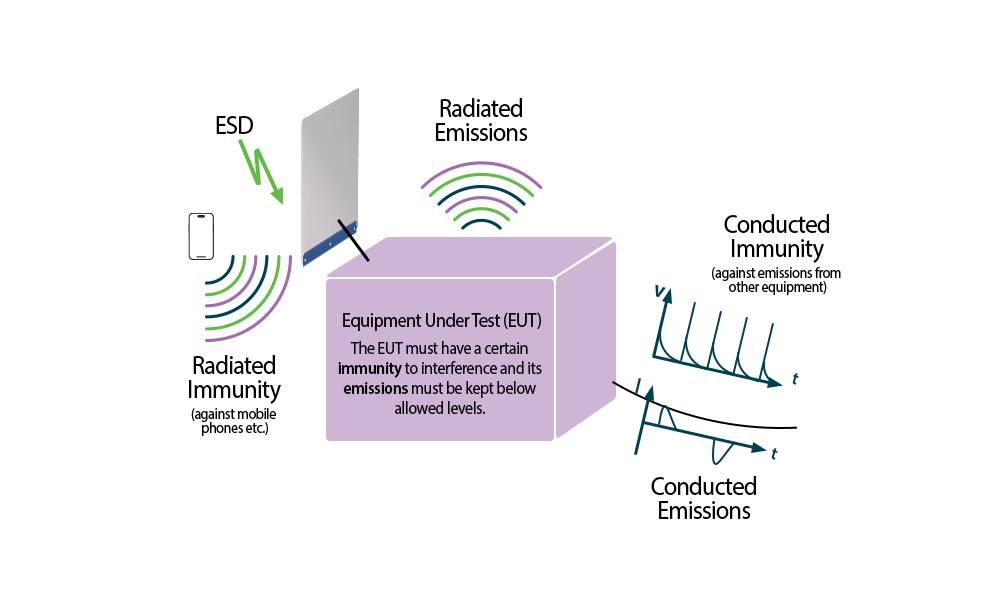

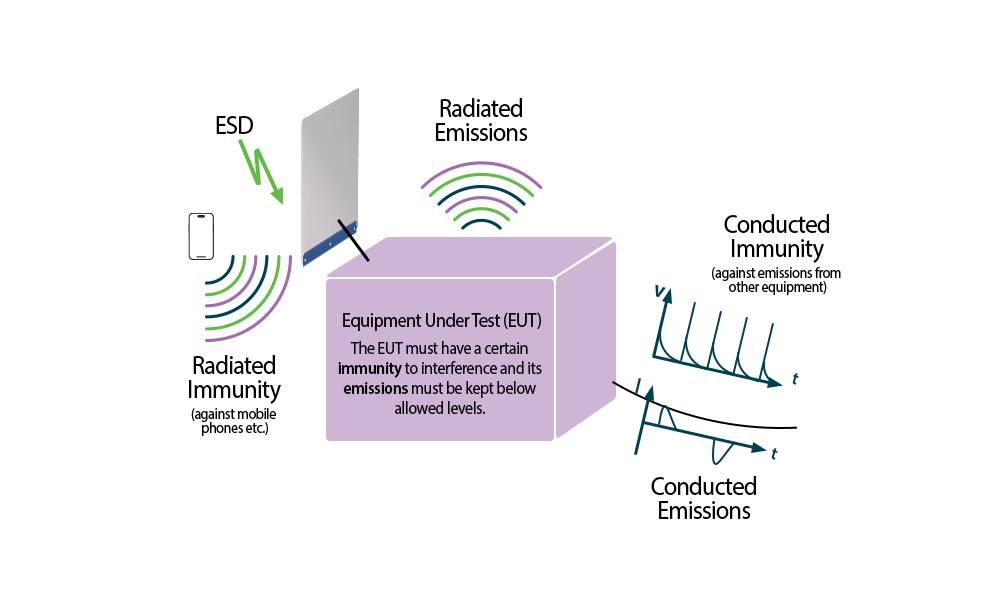

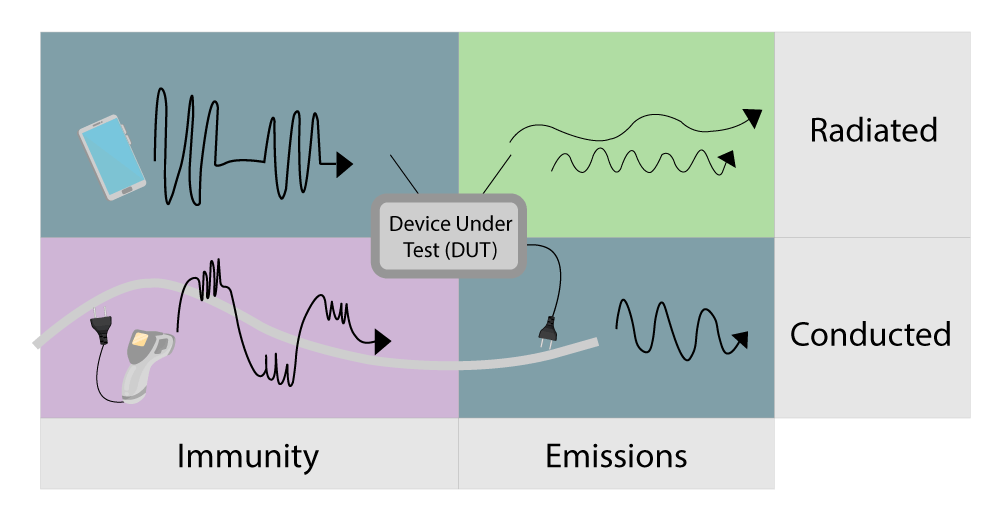

Conducted vs radiated emissions

Conducted and radiated emissions aren't entirely separate EMC phenomena but are closely related. Conducted noise on power and data cables can turn into radiated emissions, and the cables then act as antennas, especially above 30 MHz. This is actually one of the most common reasons products fail radiated emissions testing in the 30-100 MHz range.

The 30 MHz split exists because that's the point where cables transition from carrying noise to radiating it. Products with high conducted emissions often struggle with radiated compliance too; the two are closely linked.

To summarise

The key difference is the path. Conducted stays on the wires, while radiated travels through the air, affecting nearby electronics wirelessly.

For a complete understanding of radiated emissions requirements and how they relate to your conducted emissions test strategy, see our detailed guide on radiated emissions testing.

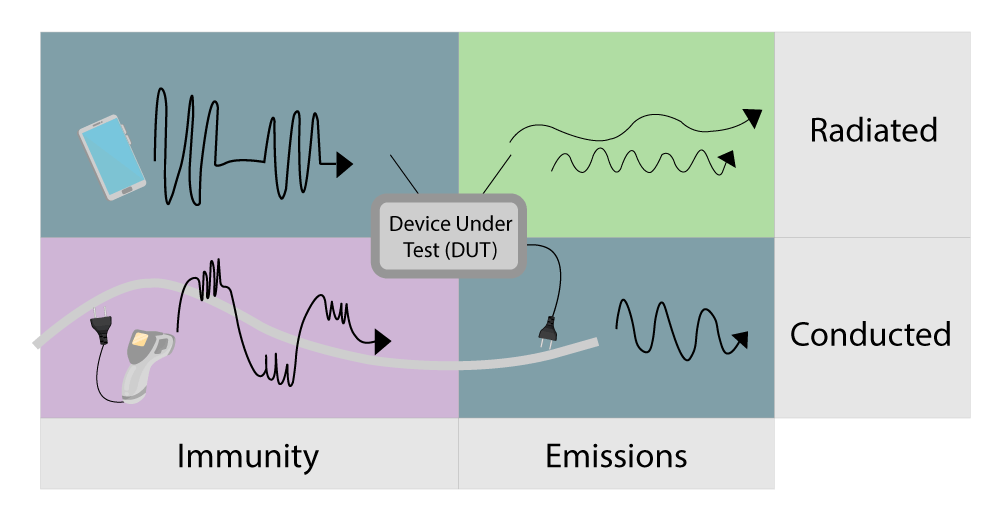

Emissions vs immunity

EMC testing splits into two sides, emissions and immunity. Emissions testing (like this guide covers) measures what your product puts out (the noise it generates). Immunity testing is the opposite; it checks whether your product can handle interference coming in from external sources.

Conducted emissions testing measures the noise a device sends down the power cable. Conducted immunity is the opposite; noise is injected into the cable to check if the device will still work under test.

Both matter for compliance. If you're setting up a full EMC test capability, you'll need to cover both sides.

Why does conducted emissions testing matter?

Conducted emissions can propagate through building wiring and affect equipment connected to the same electrical circuit. Imagine a switching power supply injecting noise onto the mains supply; that noise can travel through the building's electrical infrastructure and interfere with sensitive measurement equipment such as audio systems or communication devices. In industrial settings, this can disrupt safety-critical equipment. Regulatory bodies worldwide recognise this risk. Every major market requires conducted emissions compliance before products can be sold.

Industry-specific conducted emissions standards

Defence

Applies to military systems, equipment and subsystems across all platforms to ships, aircraft, ground vehicles and space systems.

Military limits are typically more stringent than commercial standards due to the sensitive electronics and communication systems.

(MIL-STD-461G CE101 & CE102)

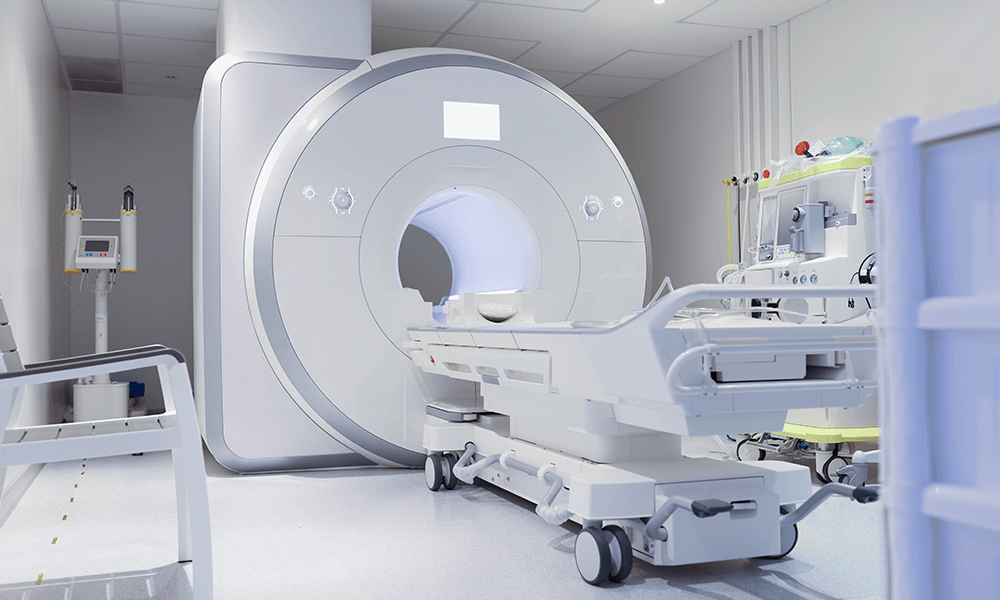

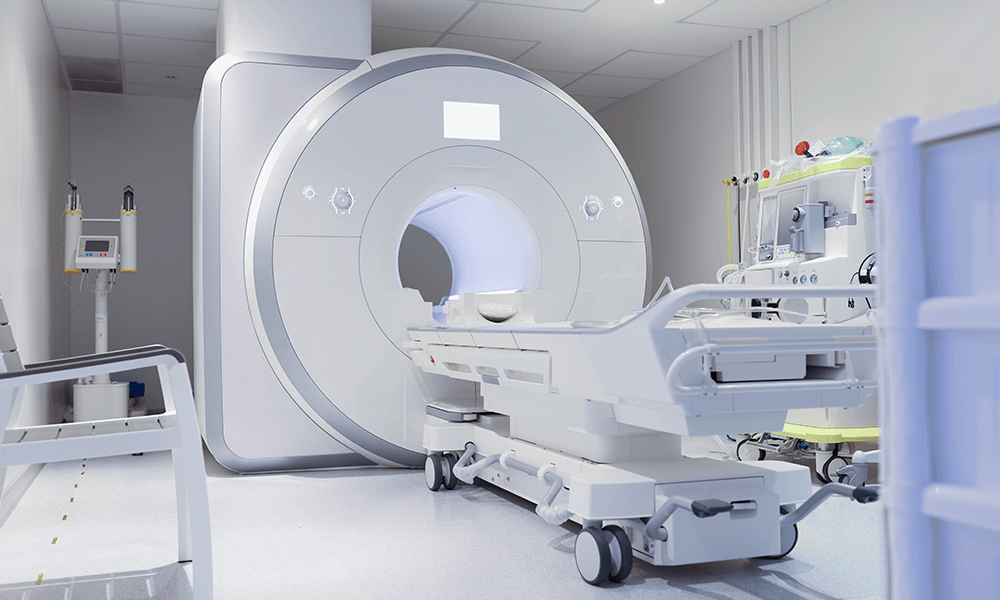

Medical

Medical electrical equipment must meet conducted emissions requirements that protect both patients and other medical devices from interference.

The consequences of EMI in medical settings can be life-threatening, making compliance particularly critical. (CISPR 11/IEC 60601-1-2)

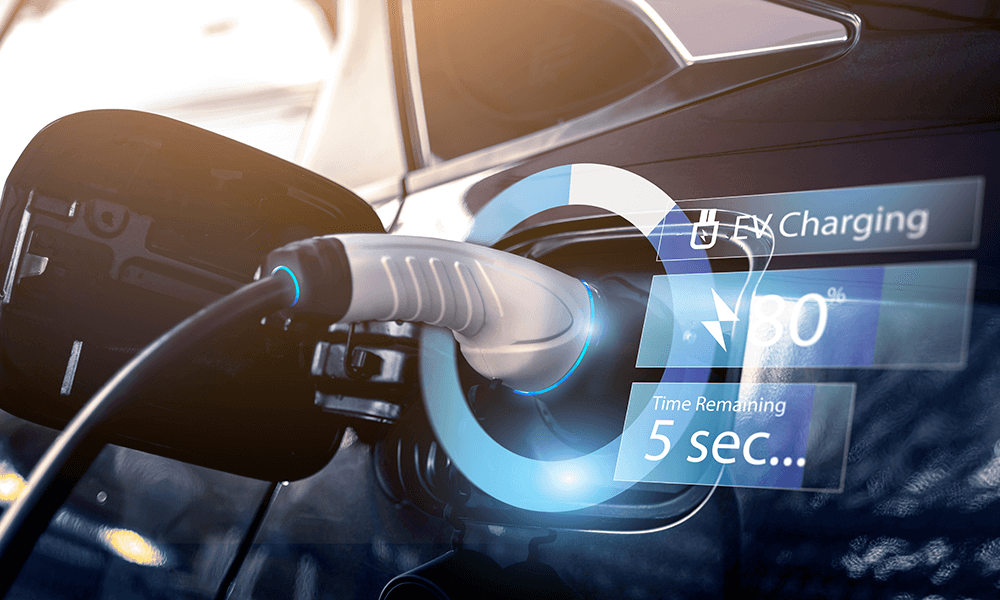

Automotive

Vehicles contain numerous electronic systems that must coexist without interference.

Conducted emissions requirements ensure that components like engine control units, infotainment systems and safety electronics don't compromise each other's operation.

(CISPR 25)

EN 55032 CISPR 16: how the standards fit together

The role of EN 55032 (CISPR 32)

EN 55032 / CISPR 32 sets the allowable limits for conducted and radiated EMI. These limits are divided into Class A and Class B, with Class B being more stringent because it applies to equipment intended for residential environments, such as consumer electronics, office devices and multimedia products.

Class A limits, however, are less strict and apply to equipment intended for industrial or commercial environments, such as motor drives, HVAC systems and industrial PCs.

EN 55032 / CISPR 32 also defines the pass/fail criteria that a DUT/EUT must meet, along with the specific port types to be assessed, including AC mains, DC power, telecom and signal ports.

The role of CISPR 16

While CISPR 16 is fundamental to EN 55032, it specifically defines how conducted emissions measurements must be performed. CISPR 16 sets the requirements for the equipment used in the test, including:

- EMI receivers/ Line Impedance Stabilisation Network (LISN)

- Detectors (QP, AVG, PK)

- LISN characteristics

- Bandwidths, sweep rates and uncertainty

This mapping helps teams understand why test equipment must be fully CISPR-compliant.

The role of the LISN (Line Impedance Stabilisation Network)

The LISN is at the centre of any conducted emissions test setup. It serves three critical functions:

- Standardised impedance to the Equipment Under Test (EUT)

- Isolating the measurement from external mains noise

- Coupling the conducted emissions to the measuring receiver

CISPR 16-1-2 specifies the LISN impedance as 50 Ω || 50 µH + 5 Ω, ensuring the EUT is always tested against a consistent and controlled impedance across the full measurement range. This consistency makes results between test labs comparable. This is why an in-house test system is often the preferred, cost-effective choice, allowing engineers to test as they design, spot issues earlier and minimise the risk of late-stage failures.

LISN vs Artificial Mains Networks (AMN) terminology

LISNs are sometimes referred to as Artificial Mains Networks (AMNs), but the two terms are not identical. AMN is the broader term defined in the CISPR standards, while a LISN specifically performs the impedance stabilisation function. In conducted emissions testing to EN 55032, a V-network AMN is typically used, which effectively operates as a LISN.

Detector types

EMI receivers have different detector modes. Which one you use matters, as certain standards specify particular detectors for compliance measurements.

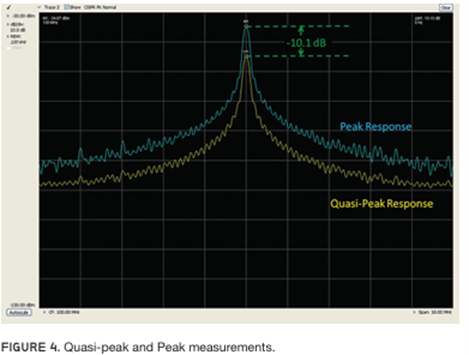

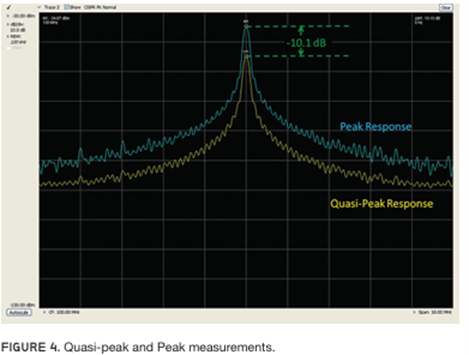

Quasi-Peak (QP)

The traditional detector used for compliance testing. It weights signals based on their repetition rate. Continuous noise produces a higher reading than infrequent spikes. Measurements take longer, but QP is required by most EMC standards.

Average (AVG)

Measures the mean level over time. Many standards now let you use average limits as an alternative to quasi-peak, which speeds up testing.

Peak (PK)

Captures the maximum. This is for quick pre-scans - if your peak measurement is under the QP limit, you're compliant at that frequency without needing the slower QP measurement.

Test equipment required for conducted emissions testing

Measurement equipment within a controlled environment for conducted emissions consists of the following:

- A LISN to provide the required 50 Ω / 50 µH line impedance

- A ground reference plane bonded to the LISN

- The EUT placed on an insulating table

- A CISPR-16 compliant EMI receiver

- Controlled cable lengths (typically 1 metre)

- A shielded room or RF enclosure for noise-free measurement

Conducted emission test environment

Conducted emissions testing should be performed in a controlled EMC environment to ensure stable, repeatable measurements.

Unlike radiated emissions, which require semi-anechoic chambers or OATS, conducted emissions testing benefits most from environments designed to minimise external RF interference and maintain consistent electrical references.

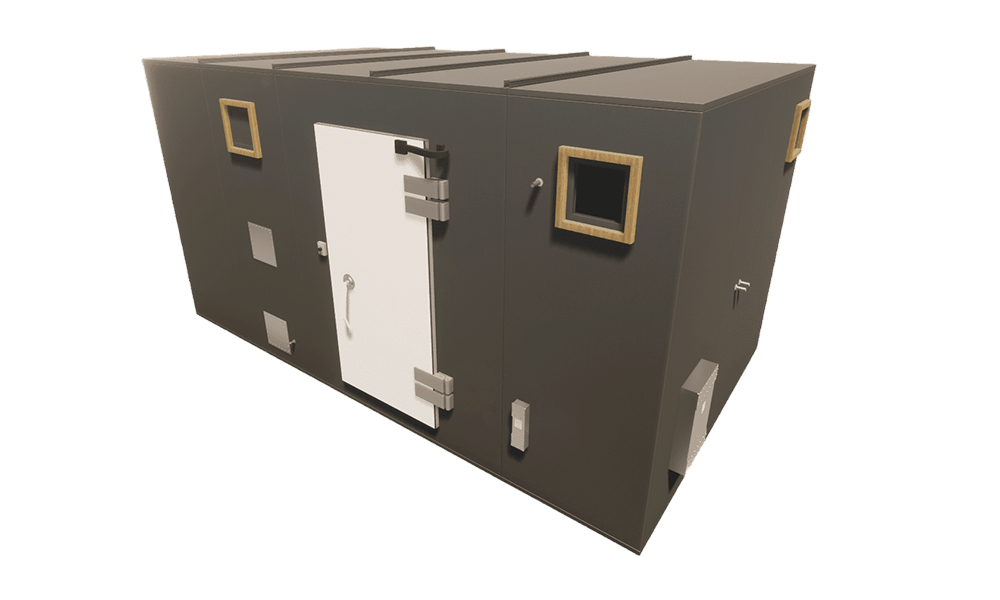

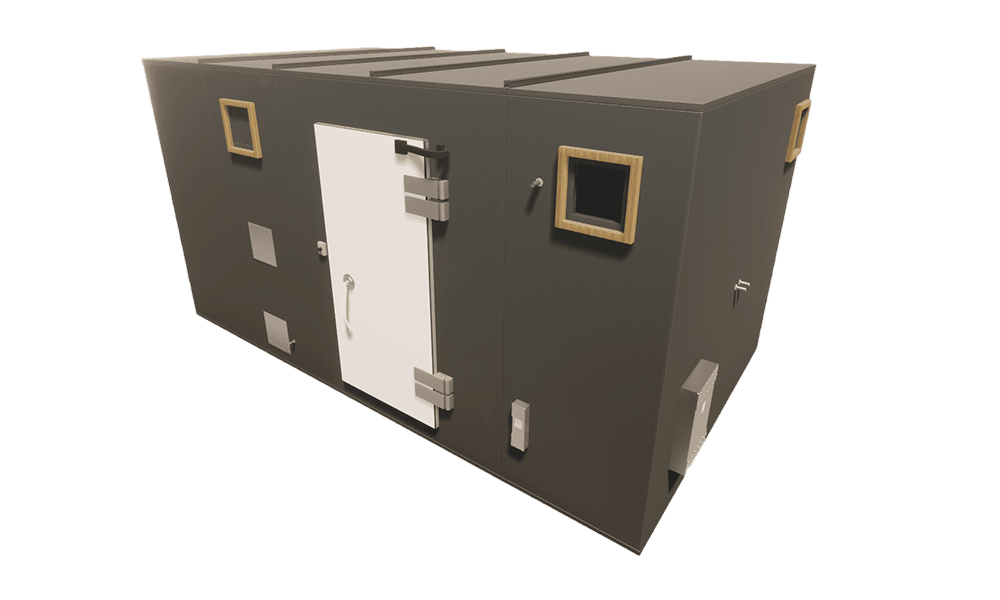

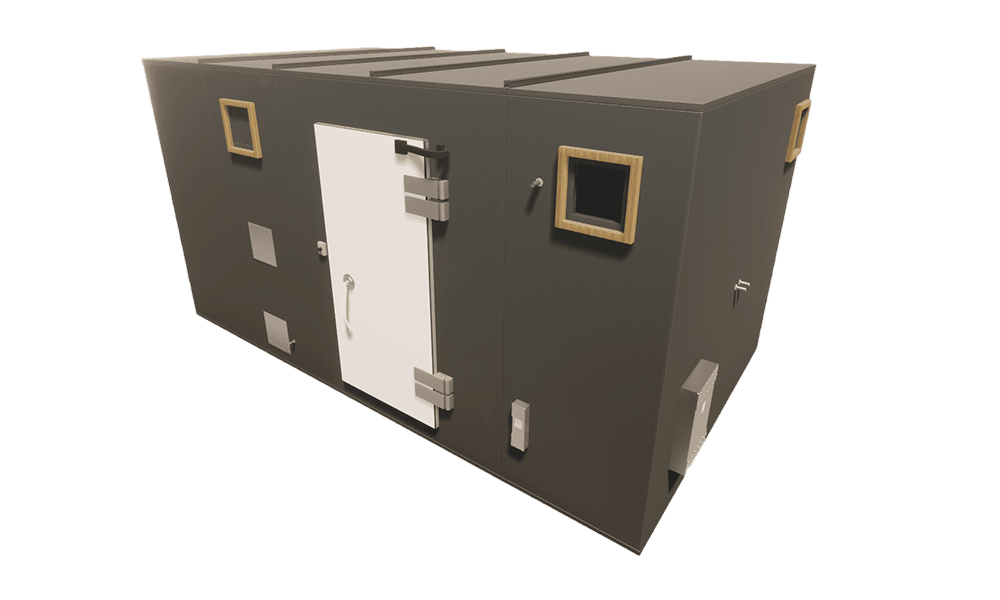

Shielded room or Faraday cage

A shielded enclosure is recommended because it prevents external RF noise from entering the setup and ensures a stable noise floor across the 150 kHz - 30 MHz conducted emissions range. This helps ensure that any emissions captured by the EMI receiver originate from the EUT alone. Shielded rooms are widely used in both accredited labs and high-accuracy in-house setups.

Related resources

Faraday cages & RFI/EMI shielded chambers by APC Technology Group

Find out what goes into building a high-performance shielded room, why it’s essential for EMC testing, and how APC can deliver a complete solution tailored to your needs.

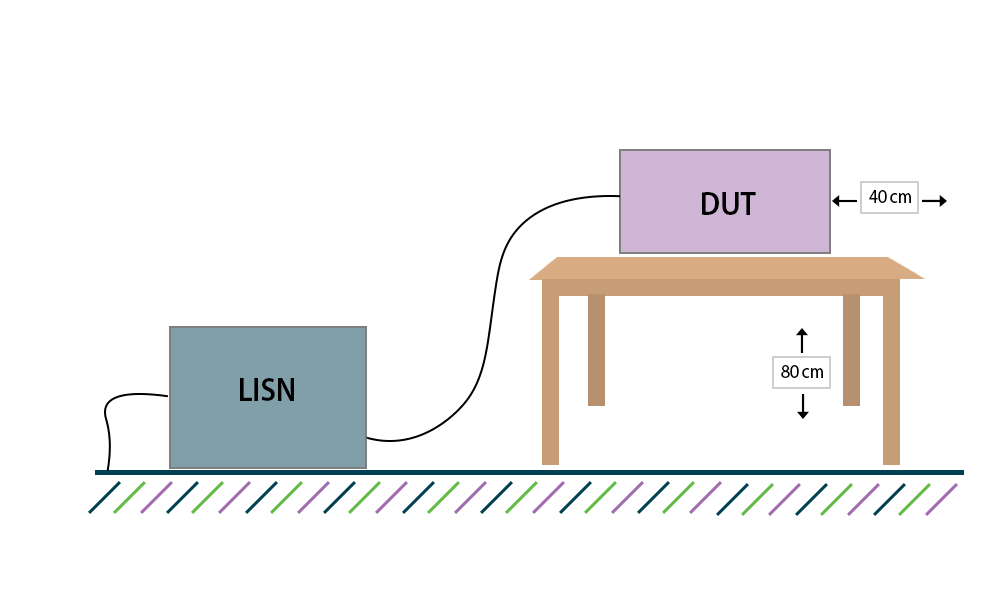

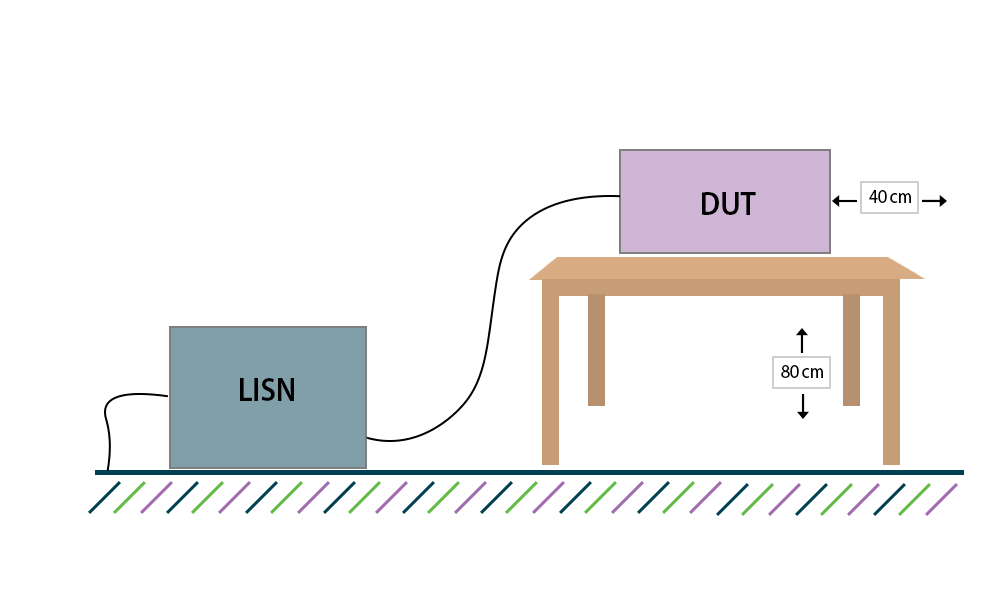

Conducted emissions test set-up

To comply with CISPR 16 and CISPR 32, the test setup must:

- Use a CISPR 16 compliant LISN/EMI receiver and cabling configuration

- Follow the exact test geometry defined in CISPR 16-2-1

- Apply the correct detectors and bandwidths

- Maintain strict control of cable length, routing and elevation

- Ensure repeatable coupling conditions via ground plane and LISN bonding

- Compare results to CISPR 32 Class A/B limits

Conducted emissions test equipment supplied by APC Technology Group

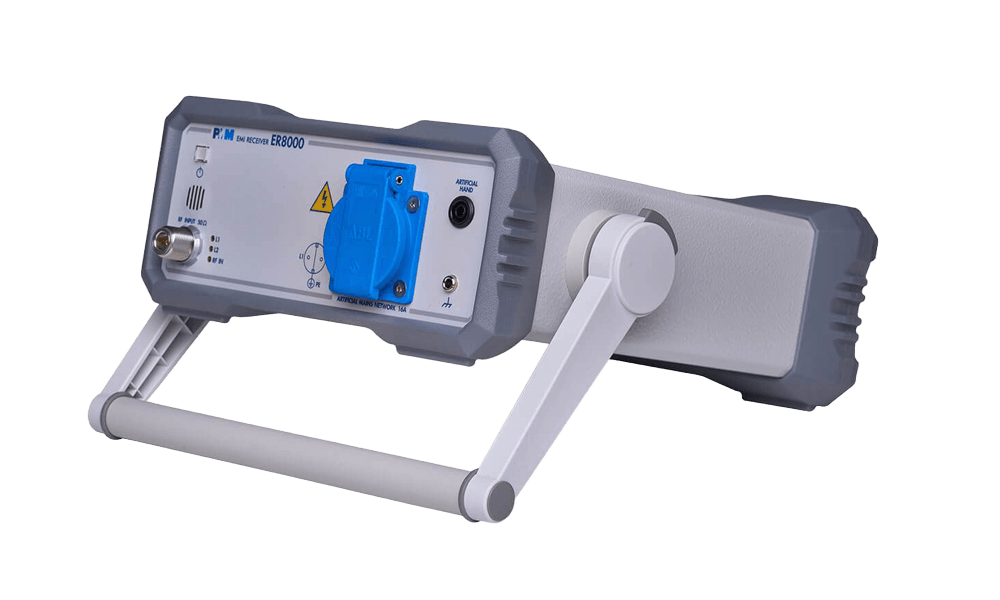

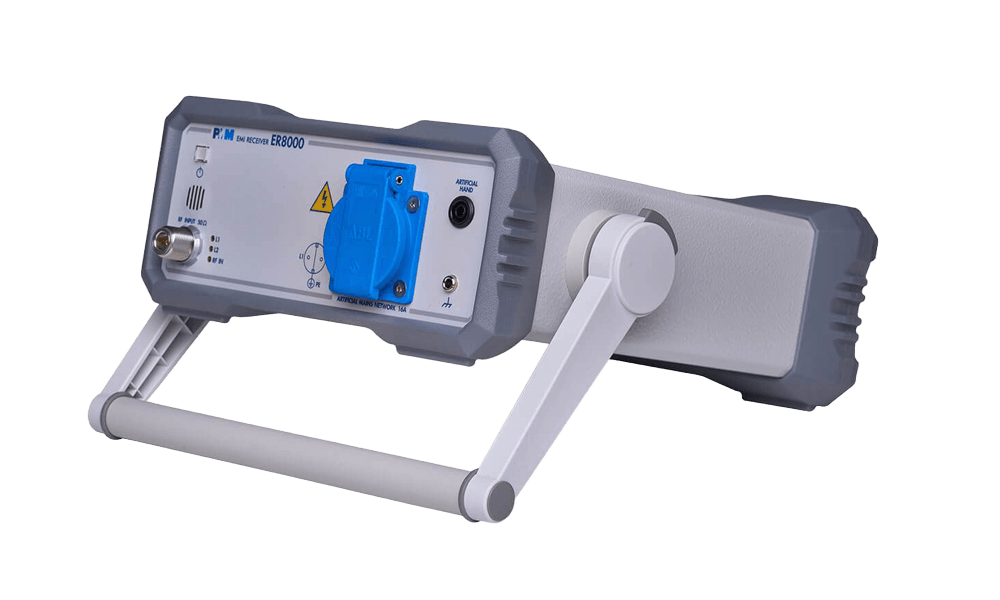

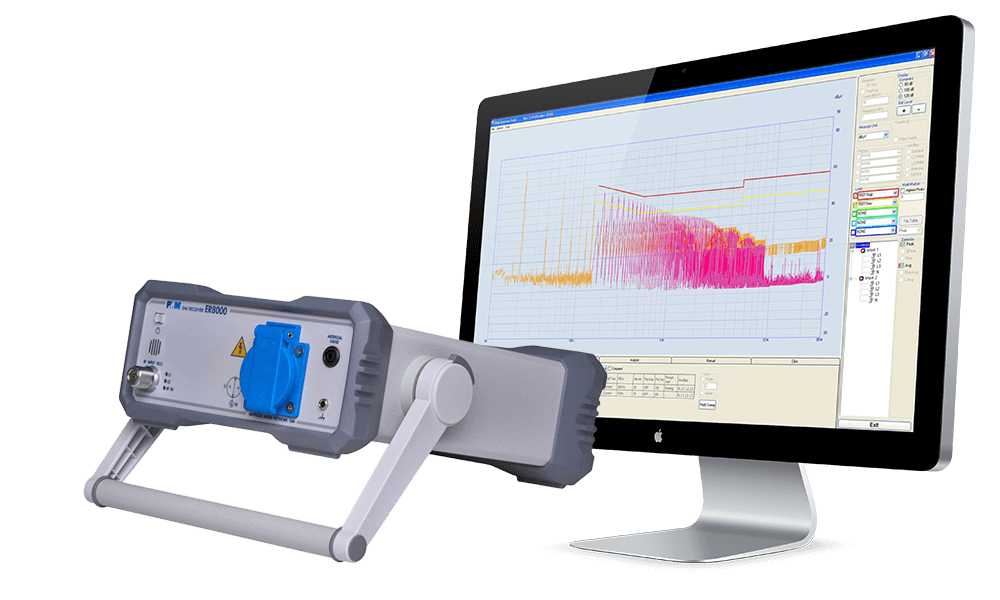

Bundle 1 - EMI receiver (9 kHz - 30 MHz) with internal LISN

Bundle 1 is a compact, CISPR 16-1-1–compliant solution focused on the 9 kHz–30 MHz band used for conducted emissions to CISPR 32. It combines an FFT EMI receiver with an internal 16 A LISN, providing a defined 50 Ω || 50 µH + 5 Ω impedance and compliance from 150 kHz to 30 MHz.

Best for: Dedicated conducted emissions testing, low-frequency support and pre-compliance labs.

Bundle Highlights:

- FFT EMI Receiver with LISN

- CISPR 16-1-1 full compliance 9 kHz - 30 MHz

- MIL STD 6 dB RBW IF filters from 100 Hz to 3 MHz

- Internal LISN 230 VAC - 16A, full compliance 150 kHz - 30 MHz

Standard Accessories:

- AC/DC converter with plug adapters

- AC cable for internal LISN

- PES Emission Suite

- USB, RS-232 cables

- USB/RS-232 serial converter

- N (m) - BNC (f) Adapter

- Soft Accessory Pocket

- Ground Connection Kit

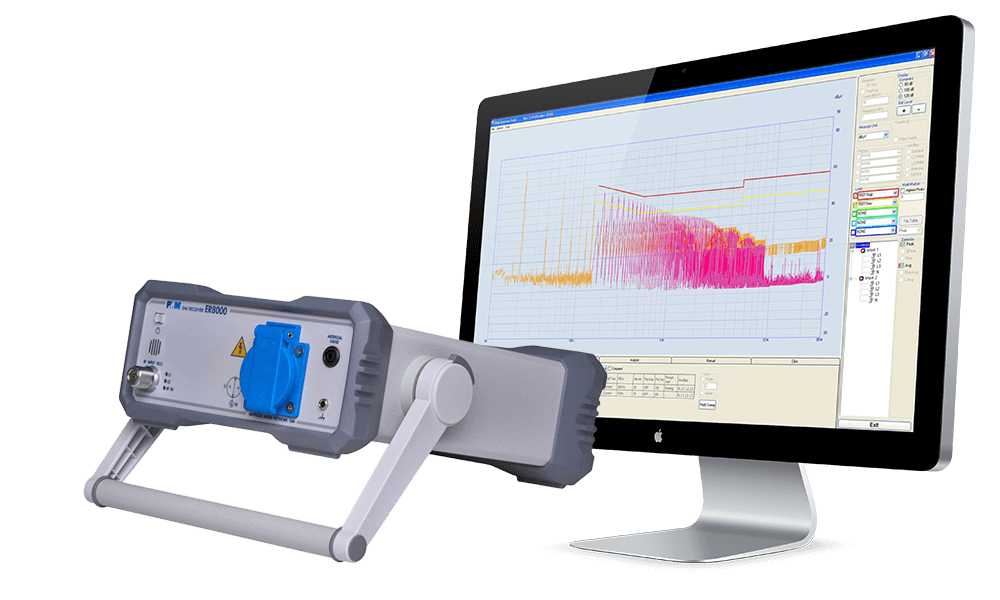

Bundle 2 - EMI receiver (9 kHz - 3 GHz) with internal LISN

Best for: Organisations building a test lab that must handle both conducted and radiated measurements, this bundle offers a scalable path. Start with conducted emissions and expand into radiated testing without replacing the core receiver.

Bundle Highlights (Everything in Bundle 1 Plus):

- Extended frequency range to 3 GHz

- Full radiated-emissions detector set (QP, AVG and PK)

- Higher-band measurement capability for modern digital equipment

- Chamber-ready calibration profiles

Standard Accessories:

- AC/DC converter with plug adapters

- AC cable for internal LISN

- PES Emission Suite

- USB, RS-232 cables

- USB/RS-232 serial converter

- N (m) - BNC (f) Adapter

- Soft Accessory Pocket

- Ground Connection Kit

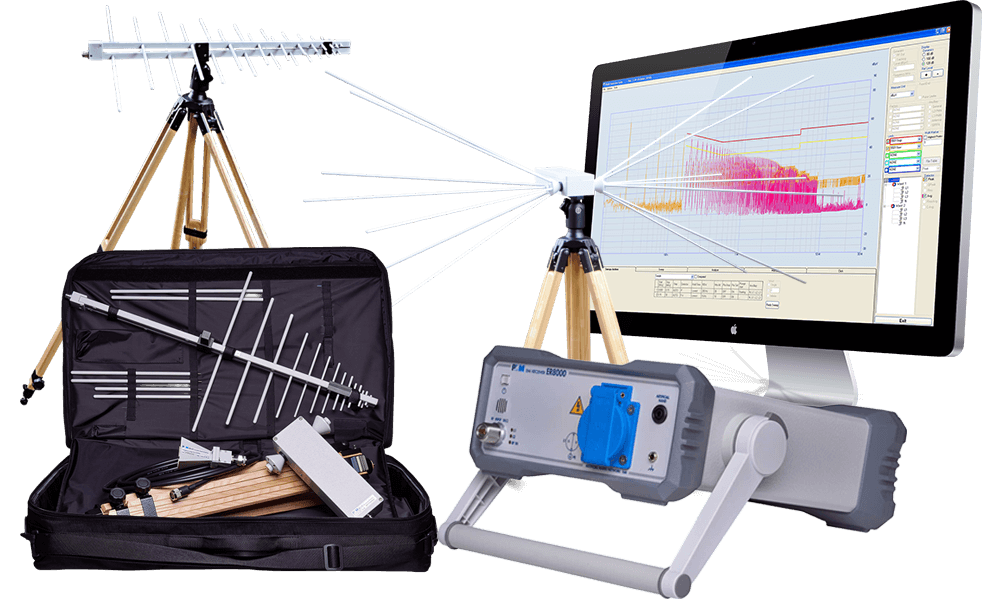

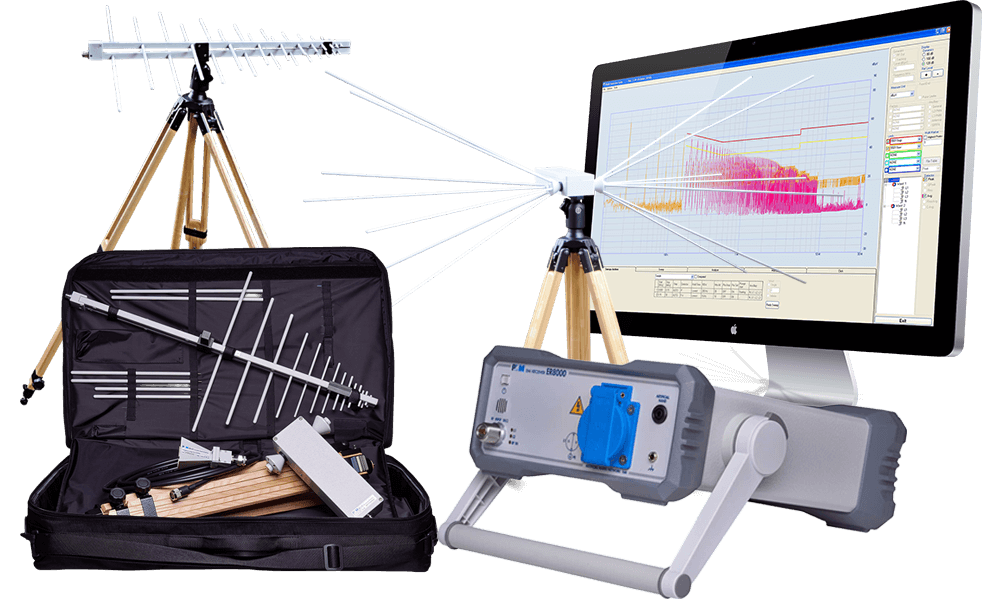

Bundle 3 - EMI receiver (9 kHz - 3 GHz) with AS-02 antenna set

Bundle 3 includes everything in Bundle 2 and adds the AS-02 calibrated antenna set (BC-01 biconical 30 - 200 MHz and LP-02 log-periodic 200 MHz - 3 GHz).

By pairing the 9 kHz–3 GHz EMI receiver with the antenna set, engineers gain a complete emissions test chain ready to plug into an existing shielded room or semi-anechoic chamber, with conducted and radiated measurements handled by one platform.

Best for: Combining conducted and radiated testing in one.

Bundle Highlights (Everything in Bundle 2 Plus):

- AS-02 calibrated antenna set including 2 antennas (30 MHz to 3 GHz):

- BC-01 Biconical Dipole

- LP-02 Log Periodic Dipole Array

- Calibration certificates

- Antenna mounts and adaptors

Standard Accessories:

- AC/DC converter with plug adapters

- AC cable for internal LISN

- PES Emission Suite

- USB, RS-232 cables

- USB/RS-232 serial converter

- N (m) - BNC (f) Adapter

- Soft Accessory Pocket

- Ground Connection Kit

Compare which bundle is right for your conducted emissions test setup

|

Feature |

Bundle 1 |

Bundle 2 |

Bundle 3 |

|

Frequency range |

9 kHz - 30 MHz |

9 kHz – 3 GHz |

9 kHz – 3 GHz |

|

Conducted emissions |

|

|

|

|

Internal LISN |

|

|

|

|

Radiated emissions support |

Limited (low-frequency only) |

Full (up to 3 GHz) |

Full (up to 3 GHz) |

|

Antenna set included |

|

|

|

|

Best use cases |

Conducted emissions only |

Conducted & radiated with one receiver |

Complete emissions ecosystem (conducted & radiated) |

|

Chambers/OATS ready |

Partial |

Yes |

Yes |

|

Pre-compliance workflows |

|

|

|

|

Full-compliance capability |

Conducted only |

Conducted & Radiated |

Conducted & Radiated |

Summary

- Bundle 1: Gives you a dedicated conducted emissions station with everything needed for repeatable, CISPR-compliant testing

- Bundle 2: Adds full radiated emissions measurement capability, making it ideal for labs wanting to consolidate both test types into one system

- Bundle 3: Delivers a complete emissions ecosystem, pairing the 9 kHz - 3 GHz receiver with calibrated antennas to cover the entire CISPR 32 spectrum from 9 kHz to 3 GHz in one turnkey solution

All three bundles include software, accessories and a CISPR-aligned measurement chain, allowing teams to build in-house EMC capability quickly and confidently, with insight, training and support from APC's specialist Test Solutions team to help you get up and running with your new equipment.

Common causes of conducted emission failures and pitfalls

One of the most common causes of conducted emission failures is excessive noise on the mains or DC supply lines generated by switching power supplies, fast digital transitions and poorly controlled return paths. These sources often produce significant energy in the 150 kHz - 30 MHz band, where CISPR 32 clauses 4 and 5 define the appropriate limits for multimedia equipment.

Conducted emissions behaviour is highly dependent on internal power stage design. Variations in PCB layout, grounding, filter placement and cable impedance can lead to large differences in measured results. Because these factors interact with the controlled test geometry, emissions measured on a bench setup frequently do not match the results obtained using a compliant LISN and ground plane.

These challenges demonstrate why many engineering teams prefer to establish an in-house conducted emissions capability early in the design cycle.

Using the same measurement conditions specified in CISPR 16 allows engineers to detect issues sooner, iterate with confidence and reduce reliance on external labs.

This is where APC Technology Group’s complete EMC ecosystem supports engineering teams. From early-stage design considerations to fully equipped chambers, compliant test equipment, installation and long-term support, APC provides a turnkey pathway to building reliable in-house EMC capability.

By working closely with industry-leading EMC solution providers, APC’s Test Solutions team offers practical, first-hand technical support to help customers overcome EMC challenges and achieve reliable first-time compliance.

Bring conducted emissions testing in-house with APC

Below are some examples of how APC can support you with your test setup and equipment requirements to fit your long-term testing needs.

|

One-time equipment cost |

|

|

Immediate testing, no scheduling |

|

|

Test immediately after every design change |

|

|

Real-time, unlimited |

|

|

Controlled and repeatable |

|

|

Development, troubleshooting and pre-compliance |

EMC radiated, conducted & immunity testing categories

Browse our full range of EMC test equipment, anechoic chambers, Faraday cages & shielded rooms

Get expert advice

Request a callback from a member of our technical team to get dedicated one-to-one consultancy for Conducted Emissions Testing, in-house capability and compliance.

Ready to bring EMC testing in-house?

Whether you're starting from scratch or upgrading an existing test area, APC supplies the full ecosystem of equipment you need to run EMC testing in-house.

From bespoke test chambers to test and measurement equipment and RF systems, APC work with customers directly to reduce outsourcing costs, shorten development cycles and gain full control over pre-compliance testing.

Your partner for reliable and compliant EMC testing solutions

With 40+ years of expertise supporting the electronics industry, APC provides high-reliability components, test equipment and engineering support for organisations building or expanding their EMC and test capabilities. As an authorised distributor for 100+ specialist manufacturers, we supply genuine, traceable equipment backed by recognised certifications.

Resources for Conducted Emissions Testing for Electromagnetic compatibility of multimedia equipment

Conducted Emissions Testing - Frequently Asked Questions (FAQs)

What's the difference between EMI and EMC?

EMC is how well a device blocks EMI.

What is the difference between conducted and radiated emissions?

Unlike conducted EMI, radiated EMI requires no physical contact; it travels through the air instead. These emissions happen when devices produce intentional or unintentional electromagnetic energy in the form of an electrical field.

What are the conducted emissions levels?

Based on the current EMC standards, conducted emissions are measured from 150 kHz and 30 MHz, however, there exists a gap in the electric power quality measured up to 2 kHz and the conducted emissions in the low frequency up to 150 kHz. The gap frequency range is termed Supraharmonics.