Bulk Current Injection (BCI) for Conducted RF Immunity Testing

CDN, EM clamp and current injection methods for Electromagnetic Compatibility (EMC)

Bulk Current Injection (BCI) is a continuous conducted immunity test method used in Electromagnetic Compatibility (EMC) to evaluate an electronic device's resilience to electromagnetic interference (EMI).

Conducted immunity testing is typically applied across a frequency range of 150 kHz to 80 MHz under the EN 61000-4-6 standard, with some sector-specific standards defining their own ranges up to as high as 400 MHz. This form of testing is widely used in automotive, aerospace and military applications and is referenced in standards such as ISO 11452-4.

Unlike emissions testing, which measures what a product radiates or conducts, conducted immunity focuses on how the device responds when exposed to external electromagnetic phenomena.

In this guide, we will outline where conducted immunity testing is most applicable, the different types of BCI test methods, the EN 61000-4-6 requirements, the equipment involved and the typical setup and calibration considerations.

Continuous vs transient EMC phenomena

Continuous testing methods are used in EMC to assess an electronic device's immunity to electromagnetic interference (EMI). Whereas transient immunity is assessed using standards like EN 61000-4-2 (ESD), EN 61000-4-4 (Fast Transient Bursts), EN 61000-4-5 (Surges) and EN 61000-4-11 (Voltage Dips & Interrupts).

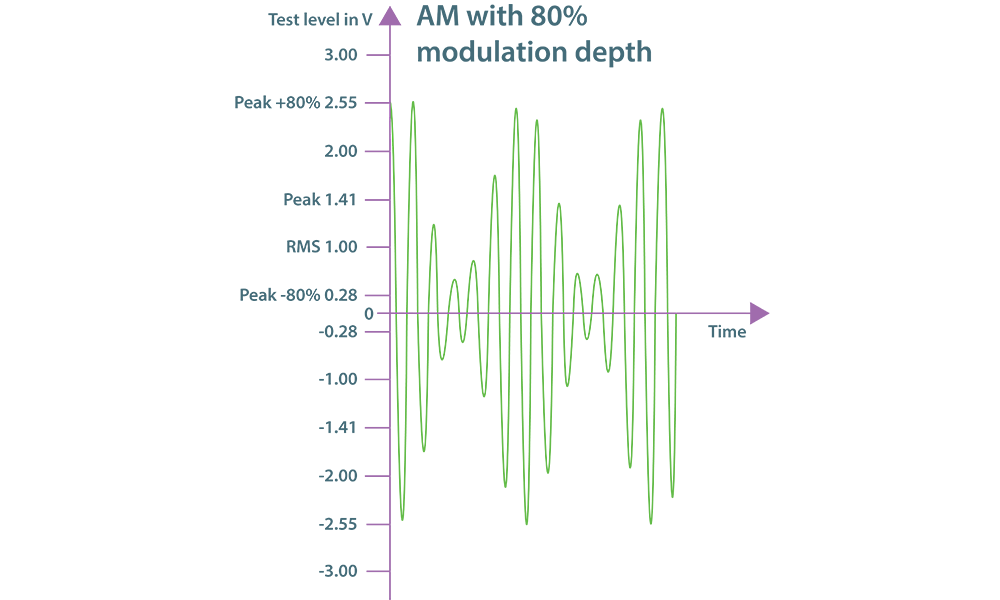

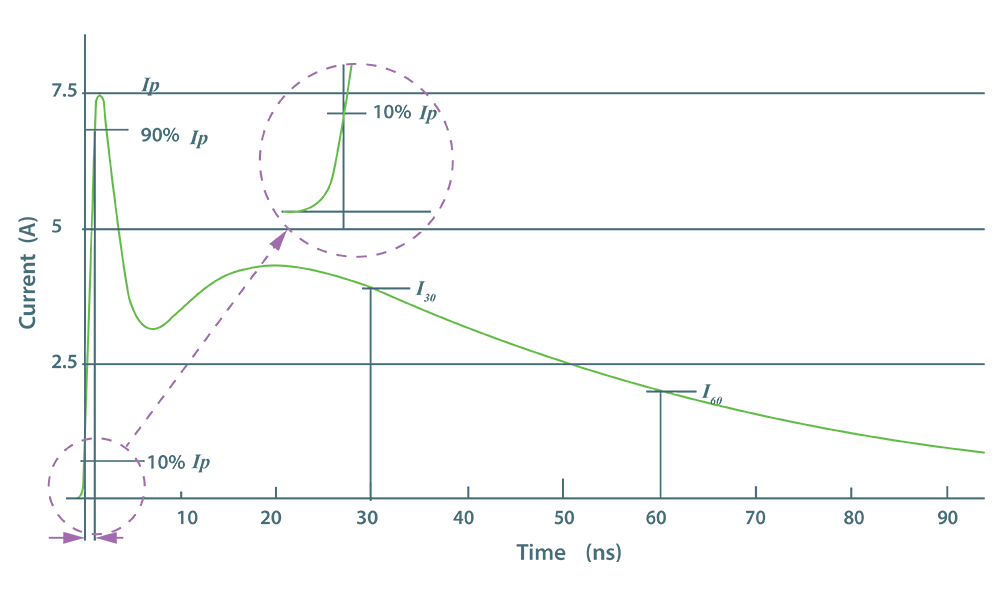

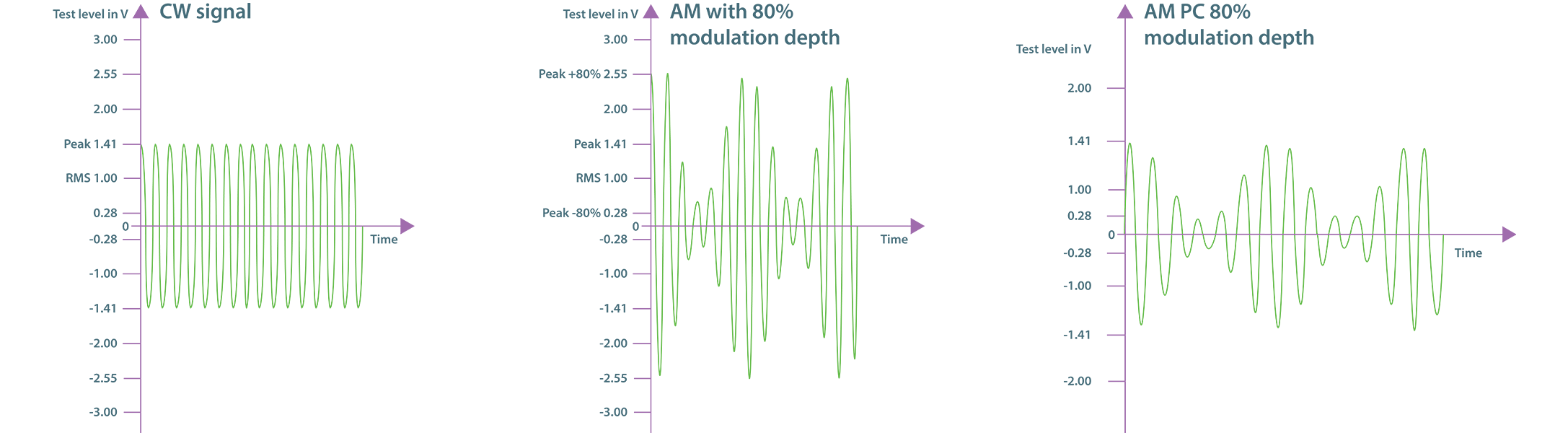

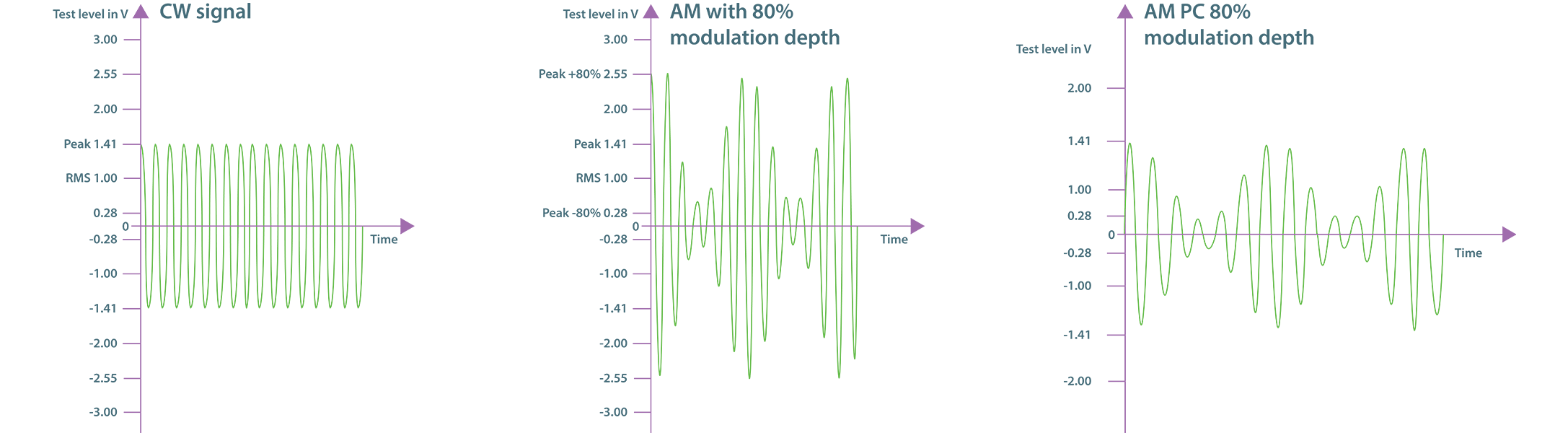

Figure 1: AM continuous electromagnetic waveform with 80% modulation depth.

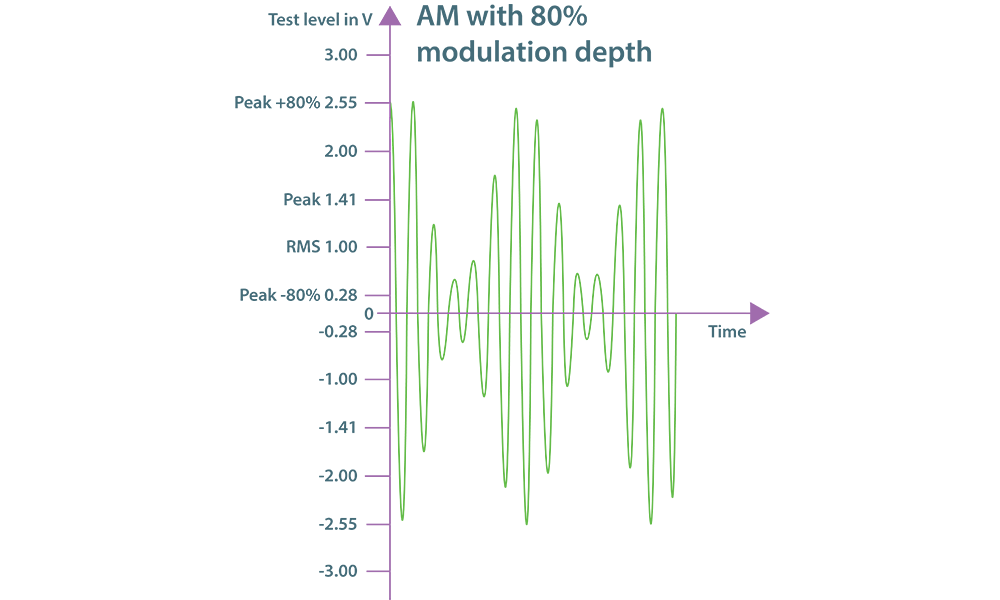

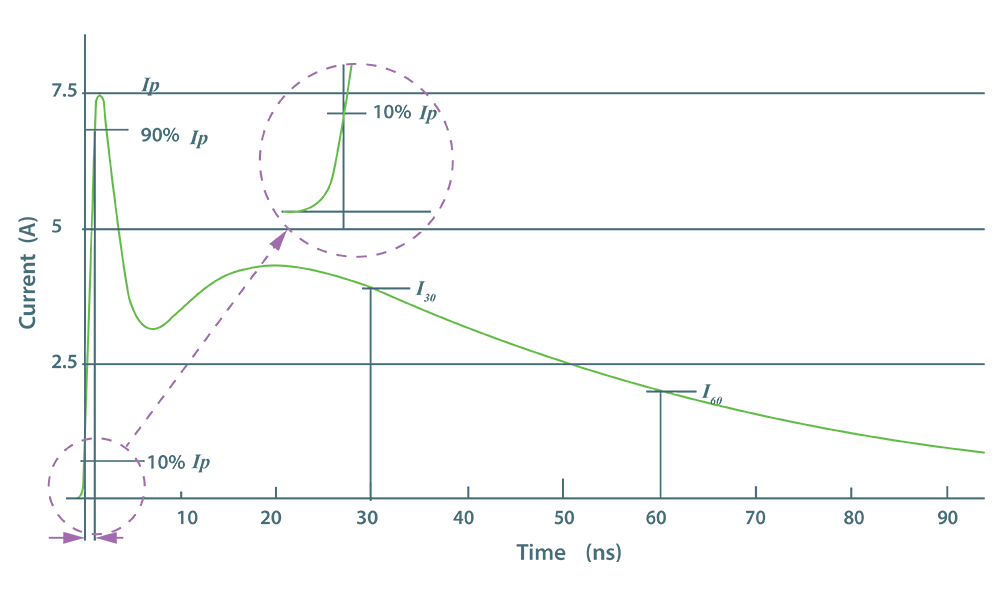

Figure 2: Transient electromagnetic waveform showing peak current (Ip), rise time (10–90% Ip), and current decay over time.

Continuous Electromagnetic Phenomena

Signals are applied to your product (DUT/EUT) for an extended period of time (seconds to minutes, depending on the duty cycle of your EUT) to simulate a continuous interference event as illustrated by the amplitude-modulated continuous waveform in Figure 1.

Transient Electromagnetic Phenomena

Short-lived, high-energy events such as electrostatic discharge (ESD), power surges, and electrical fast transients (EFT) disrupt or damage electronic systems, as illustrated by the transient current waveform shown in Figure 2.

|

Feature |

Continuous EMC Phenomena |

Transient EMC Phenomena |

|

Duration |

Long, steady application of the signal |

Short, instantaneous bursts |

|

Examples |

Ongoing radio frequency (RF) firleds, continuous modulated signals |

Electrostatic discharge (ESD), power surges and electrical fast transients (EFT) |

|

Purpose of the test |

Check a device's performance during constant EM exposure |

Check's a device's resilience to sudden, high-energy levels |

What is Bulk Current Injection (BCI)?

Bulk Current Injection (BCI) is a continuous conducted immunity method where controlled RF currents are injected into a cable harness to replicate real-world electromagnetic interference, allowing engineers to verify how the equipment under test (EUT) behaves when RF voltages or currents are present on its connected cables.

Purpose of conducted immunity testing EN 61000-4-6

EN 61000-4-6 ensures equipment can operate reliably when exposed to:

- Switching frequency noise

- Industrial RF interference

- Nearby radio transmitters

- SMPS noise coupling

- Long cable runs acting as antennas

- Noisy industrial environments

Industries that depend on conducted immunity

The EN 61000-4-6 standard is required for critical applications such as medical devices, automotive electronics and industrial control systems, where an RF interference failure could cause anything from serious safety risks to annoyance to the end user. Adequate susceptibility ensures reliable, safe and quality operation in their intended environments.

Anywhere cables act as antennas, EN 61000-4-6 matters.

Defence

Cable immunity under extreme RF conditions. (MIL-STD-461 CS116)

Automotive

Engine control units, airbags and anti-lock braking systems. (ISO 11452-4)

Avionics

Navigation, communication and flight control systems. (DO-160 Section 20)

Overview of recognised RF injection methods in EN 61000-4-6

Conducted immunity tests according to EN 61000-4-6 can be carried out in three ways

- Coupling/Decoupling Networks (CDNs): CDNs inject RF disturbance signals directly into a device's cables while also decoupling them from the auxiliary equipment, preventing interference in both directions

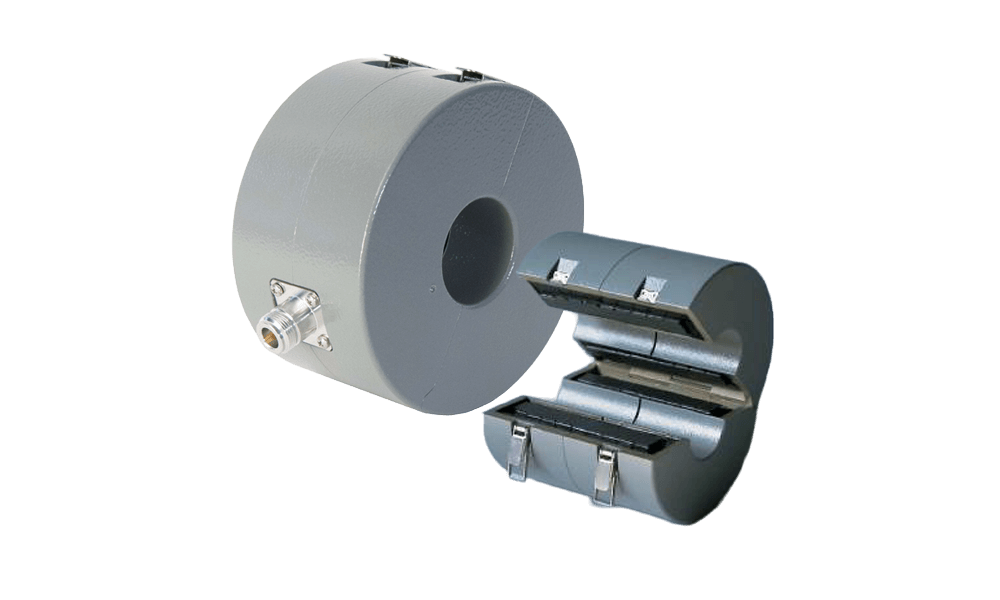

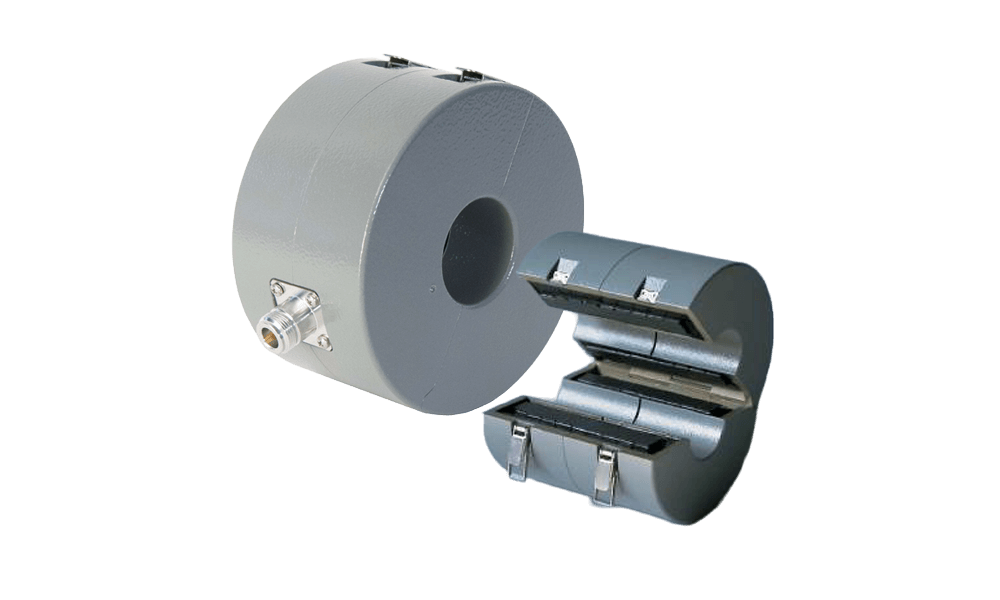

- Bulk Current Injection (BCI) Clamps (Injection Probes): Inductive probes used to perform conducted immunity tests on electronic equipment. They function like a transformer, clamping around a cable harness to inductively inject RF currents and simulate electromagnetic interference (EMI)

- EM Clamps (Electromagnetic Clamps): Injection devices used in Bulk Current Injection (BCI) testing for conducted immunity tests, particularly when standard Coupling/Decoupling Networks (CDNs) are not applicable

These methods allow test engineers to reproduce realistic RF coupling conditions across the full 150 kHz–80 MHz band.

Below we will break down how each method works, why certain product committees prefer one over another and how their performance, repeatability and practicality compare in real test environments.

Calibration & test methods in EN 61000-4-6

Why calibration is mandatory before every test

EN 61000-4-6 requires calibration before any conducted RF immunity test because each injection device, CDN, EM Clamp or Current Injection Clamps have different insertion losses and coupling behaviour. Calibration ensures the system actually delivers the required 1 V, 3 V or 10 V test level to the EUT cable, regardless of device tolerances, cable lengths, amplifier characteristics or set-up variations.

As calibration accuracy depends on all components used in the test set-up, every time a device should be re-calibrated the whole system (including Generator, Amplifier, Attenuator and RF Cables) would have to be sent back to the calibration laboratory.

CDN injection (preferred method in EN 61000-4-6)

This method is most suitable for well-defined cable types (power, signal and data), offering the highest repeatability. It is the preferred and most repeatable method defined in EN 61000-4-6, used when a suitable CDN exists for the cable type.

What coupling/decoupling networks (CDNs) do

CDNs inject RF disturbances directly onto power, data or signal conductors while maintaining the required 150 Ω common-mode system impedance and protecting auxiliary equipment through built-in decoupling networks.

Coupling/Decoupling Networks inject the RF disturbance into the cable while enforcing the mandatory 150 Ω common-mode impedance on both the EUT and AE sides. This ensures the test is globally reproducible, a core requirement of EN 61000-4-6.

How the setup works

- CDN sits between AE and EUT

- RF generator > amplifier > attenuator > CDN > EUT

- 150 Ω adapters and terminations are used during calibration only (not during the actual test)

Why CDNs are preferred

- Highest consistency

- Lowest uncertainty

- Required “whenever applicable” under EN 61000-4-6

CDNs, EM clamps and current injection clamps calibration according to EN 61000-4-6

Figure 3: EN 61000-4-6 test setup with STS Narda CDNs, EM clamps and current injection clamps.

Current injection clamp and monitoring probe according to EN 61000-4-6

Figure 4: EN 61000-4-6 test setup with STS Narda current Iijection clamp and monitoring probe.

When this method is used

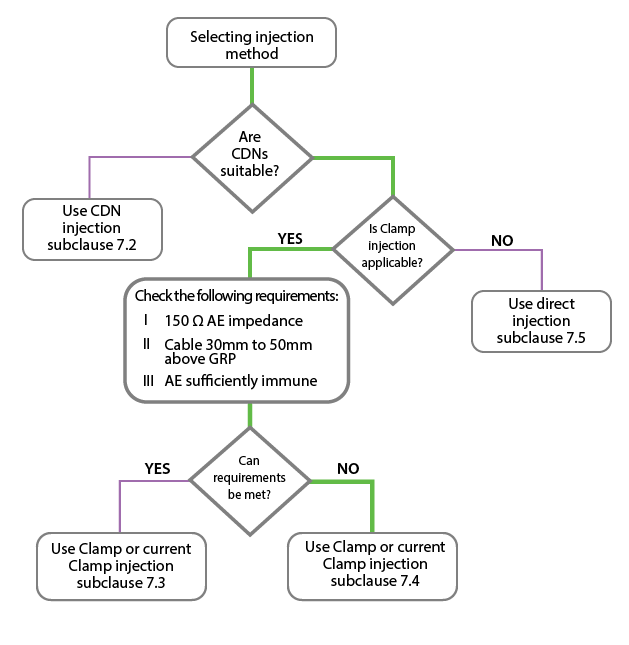

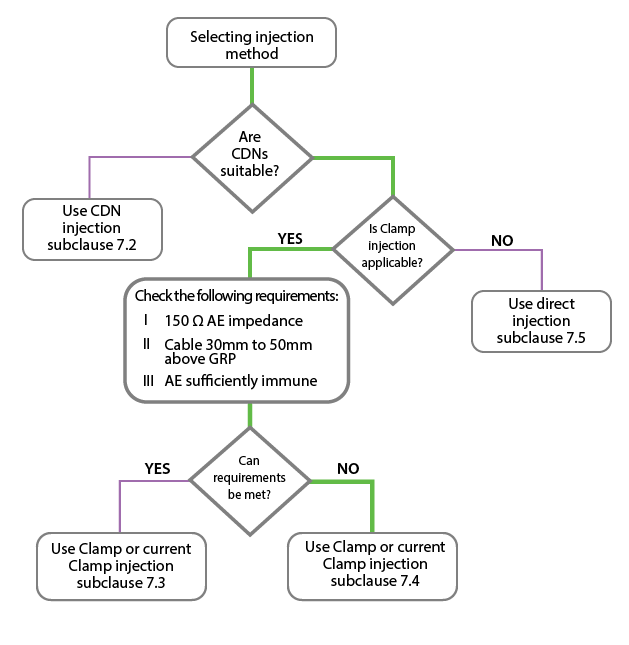

EN 61000-4-6 allows clamp-based injection only when CDNs are not suitable for the cable type.

Two versions exist in clause 7 EN 61000

Clause 7 of EN 61000-4-6 concerns the test setup and injection methods, which were reorganised in the 2014 version of the standard (subclauses 7.3 and 7.4).

- 7.3: Clamp injection without current monitoring (only if 150 Ω AE impedance is assured)

- 7.4: Clamp injection with a monitoring probe (recommended if impedance is unknown, which is almost always the case)

Why EN 61000-4-6 prefers the 7.4 Method

- Always verifies injected current

- Ensures levels never exceed Uo/150 threshold

This method is much more effective if compared to the other one using the EM Clamp, due to a less expensive configuration in terms of device used to properly inject RF stress signal and power required from amplifier.

How the setup works

- RF generator > amplifier > injection clamp

- A monitoring probe is placed on the same cable segment

- The system first measures the threshold current without modulation

- Software adjusts drive levels

- The test is executed using an AM-modulated signal - the test is then performed in 2 different steps:

- Verification of threshold current value and modification of RF generator output levels accordingly, without AM modulation superimposition

- Use of the modified generator table (frequency vs. level) to perform the test with the addition of AM modulation

RF signal modulation

There are two modulation methods used for signals during the bulk injection test, amplitude modulation (AM) and amplitude modulation with peak conservation (AM-PC). Understanding the test specification is important so you don’t over/under test your EUT.

Figure 5: RF signal modulation methods used in bulk current injection testing, showing a continuous wave (CW) signal, amplitude modulation (AM) with 80% modulation depth, and amplitude modulation with peak conservation (AM-PC) at 80%, highlighting the importance of correct modulation selection to avoid over/under-testing the EUT.

EM clamp injection (alternative method)

This method is best for shielded cables, coax, telecom or situations where a CDN is not physically compatible.

What an EM clamp does

The EM clamp applies RF energy to a cable through combined capacitive + inductive coupling, unlike a current clamp, which is purely inductive.

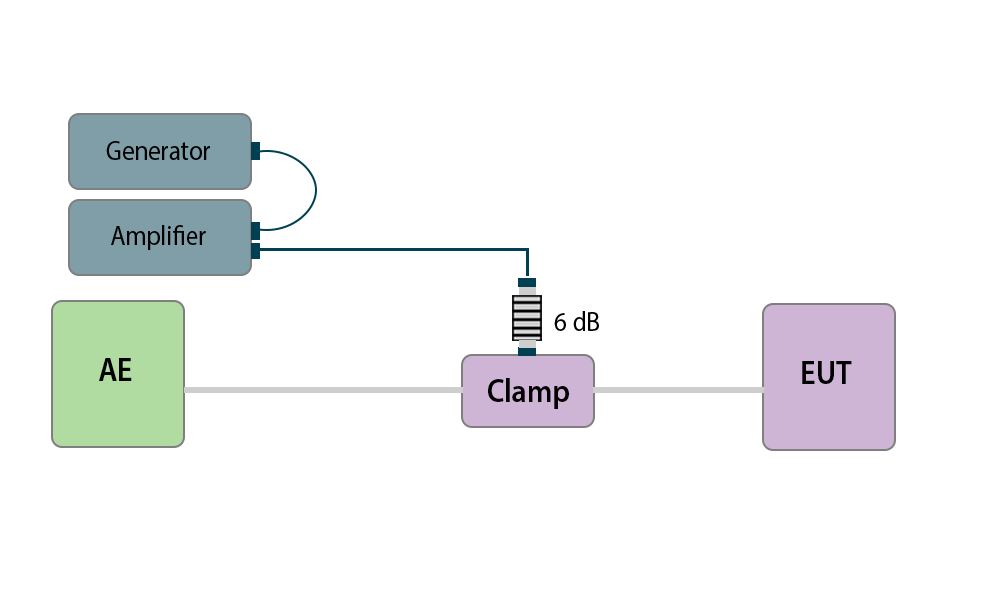

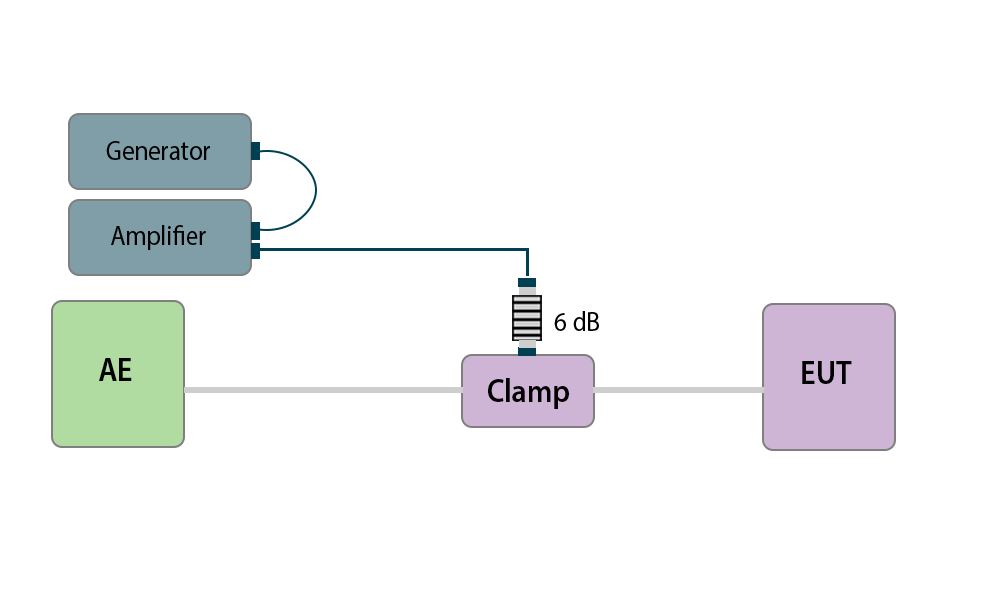

How the setup works

- EM clamp placed around a representative cable (during calibration) or the actual harness (during testing)

- Calibration setup is almost identical to CDN calibration, but substitutes the clamp in place of the CDN, still using 50–150 Ω adapters and a calibration wire

When EM clamps are used

- When the cable type prevents the use of a CDN

- When shielding makes current-clamp coupling inefficient

- When product committees specify field-coupling methods

Using EM clamps often requires more amplifier power and possibly a higher-rated attenuator.

The flowchart below is provided in the EN 61000-4-6 standard to help operators decide whether a clamp is required for a conducted immunity test. Two different set-ups are defined mainly based on the 150Ω impedance matching condition at the AE side, which may or may not require monitoring of the injected current at the EUT side (subclauses 7.3 and 7.4 in the standard).

Figure 5: EN 61000-4-6 Diagram using EM Clamp.

Figure 6: The flowchart is provided in the EN 61000-4-6 standard to help operators decide whether a clamp is required for a conducted immunity test.

Because it is quite difficult to determine whether the 150 Ω common mode impedance matching will be achieved for each specific EUT/AE combination, it seems more practical to follow subclause 7.4 by using a current monitoring probe, along with a current injection clamp.

No additional filtering devices are necessary to ensure the 150 Ω impedance matching, while the injected current is constantly monitored to prevent exceeding the threshold level of Uo/150, where Uo is the voltage test level required for that specific EUT. A 30W amplifier is typically helpful to drive such a test up to the 10V level.

|

Injection method |

How it works |

Best suited for |

Strengths |

|

CDN (Coupling/Decoupling Network) |

Injects an RF disturbance directly onto each conductor while maintaining an impedance of 150 Ω, decoupling AE to prevent back-feed |

Power lines, Ethernet, data, telecom, multi-core cables with standard connectors |

Highest repeatability and regarded as the standard-preferred method (EN 61000-4-6 Clause 7.2) |

|

EM Clamp |

Creates an RF electromagnetic field around the cable to induce disturbance currents without breaking the cable connection |

Shielded cables, coax, telecom leads, cables where insertion is undesirable |

Ideal for shielded or delicate connectors and quicker test setup compared to CDNs |

|

BCI Injection Clamp |

Applies RF current directly onto the cable harness using a current injection clamp during calibration and test |

Large harnesses, automotive, industrial control, military EMC (CS114-style test) |

Quick for complex harnesses, no cutting or modifying cable bundles and mimics real-world cable susceptibility |

Performance criteria (A, B, C)

EN 61000-4-6 typically uses:

Criterion A: No performance degradation

Criterion B: Temporary degradation allowed, self-recovery

Criterion C: Degradation allowed, operator intervention permitted. The product-specific EMC standard defines these requirements.

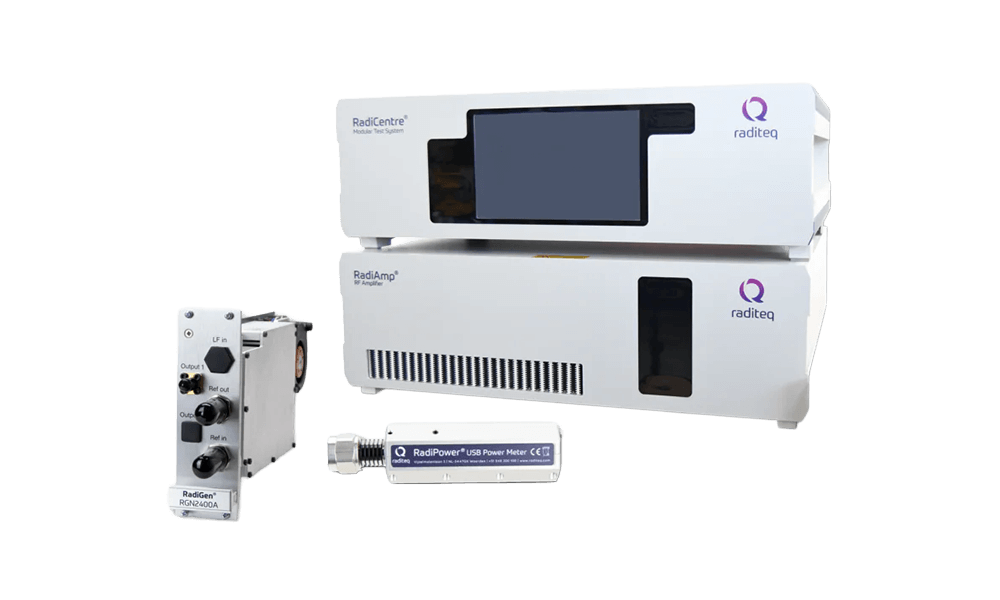

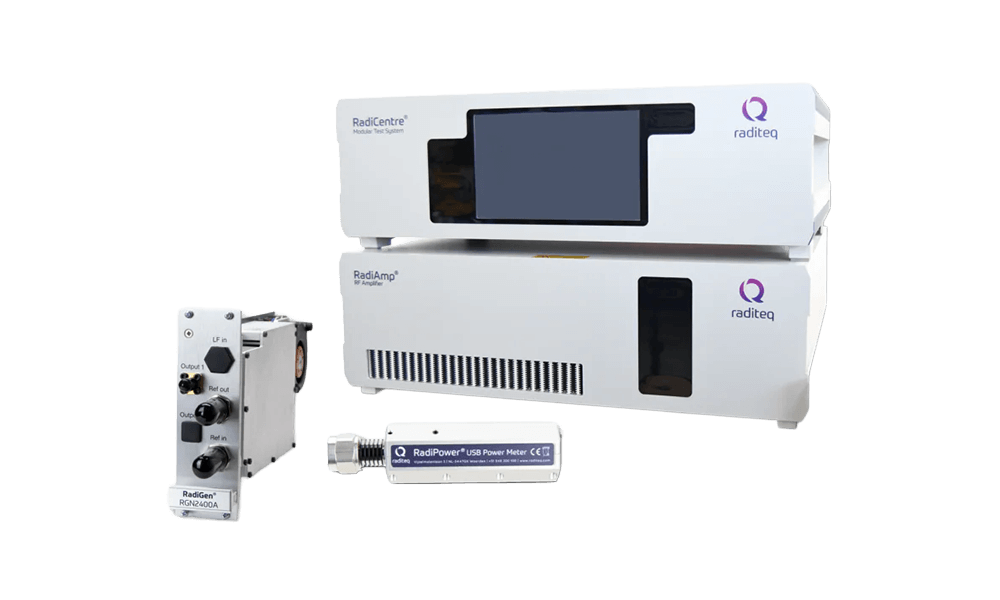

ISO 11452-4 Automotive BCI Testing Made Simple

The Raditeq CIB100B delivers 100W of RF power across 9 kHz to 400 MHz, covering the full automotive conducted immunity range. This turnkey bundle includes signal generator, amplifier, power meter and RadiMation software for automated ISO 11452-4 testing of ECUs, sensors and powertrain electronics.

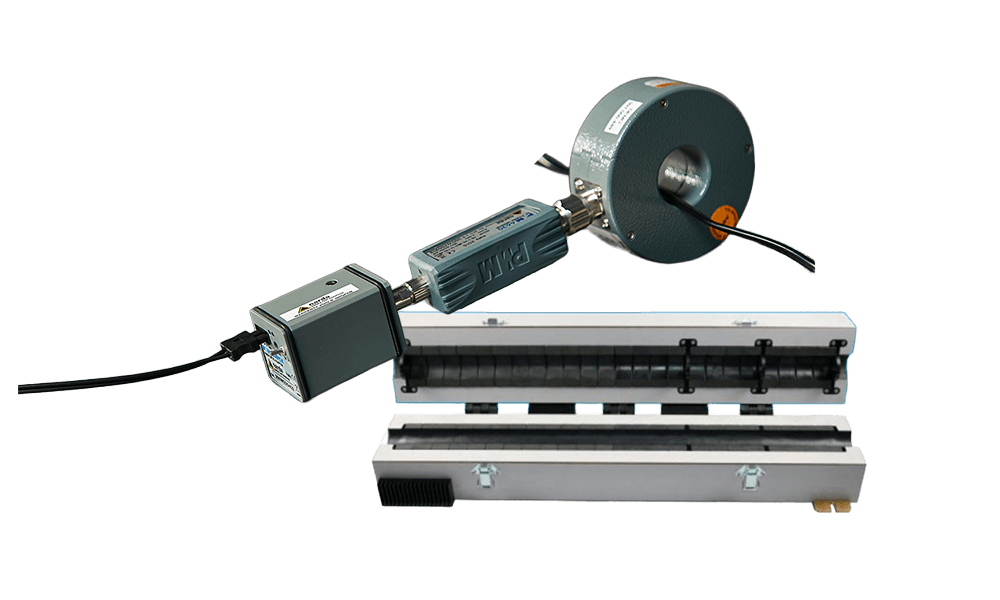

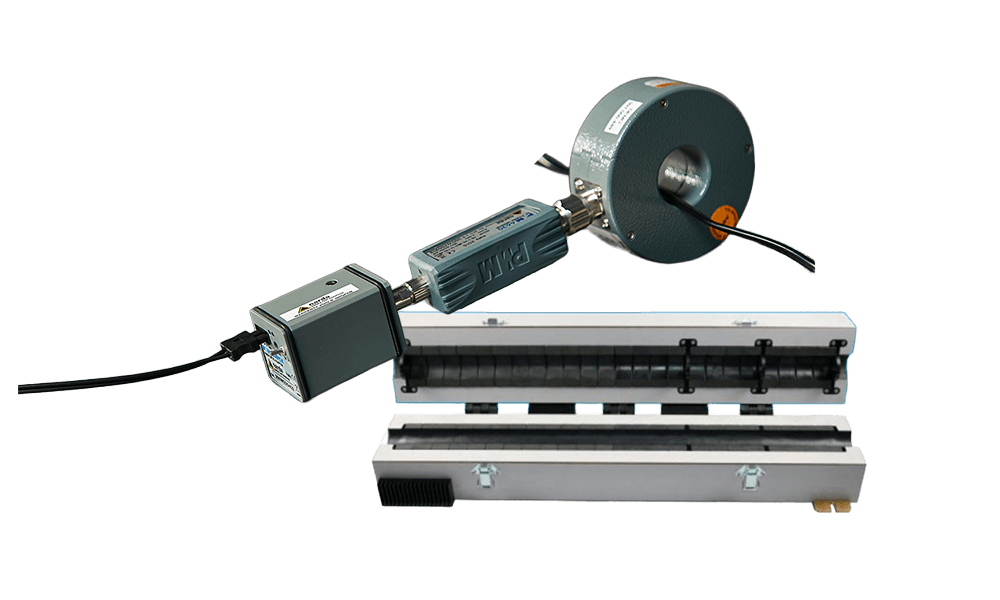

Conducted immunity test equipment - supplied by APC Technology Group

Unlike most set-ups available to engineers today, the COND-IS/10 is supplied as a fully integrated system, containing every calibrated component required for official EN 61000-4-6 testing, including the generator, amplifier, CDN, cables, attenuator and software.

Figure 7: STS Narda 6630 USB RF Power Meter, PIMS Immunity Suite Software and 6000N RF Amplifier.

Available as a bundle!

Everything you need for Conducted Immunity Testing in a bundle.

What's in the box?

- 3010 RF Generator (9 kHz – 1 GHz)

- 6000N RF Amplifier (9 kHz – 230 MHz, 10/15 W)

- ATT-25W 6 dB Attenuator

- M3-16 CDN (3 lines, 16 A per line, calibrated at 1 / 3 / 10 V)

- Cab-06 Cable Kit (complete interconnection kit)

- PIMS Immunity Suite Software (full control and calibration automation)

This means the operator can begin testing immediately, no hunting for extra accessories, impedance adapters or calibration parts.

Designed as a modular, upgradeable ecosystem

A standout feature of the COND-IS/10 is its modular architecture, which Narda designed specifically to avoid the limitations of “locked-in” compact immunity testers.

This modularity allows you to:

- Swap or upgrade the RF generator (e.g., PMM 3030 for 3 GHz immunity work)

- Add higher-power amplifiers if special test levels >10 V are required

- Integrate additional CDNs for mains, telecom, balanced, shielded & unshielded lines

- Add EM clamps, current clamps, monitoring probes and calibration kits

Expand into radiated immunity using the same power meter and software. In practical terms, this makes the COND-IS/10 future-proof, ideal for labs anticipating evolving EMC requirements.

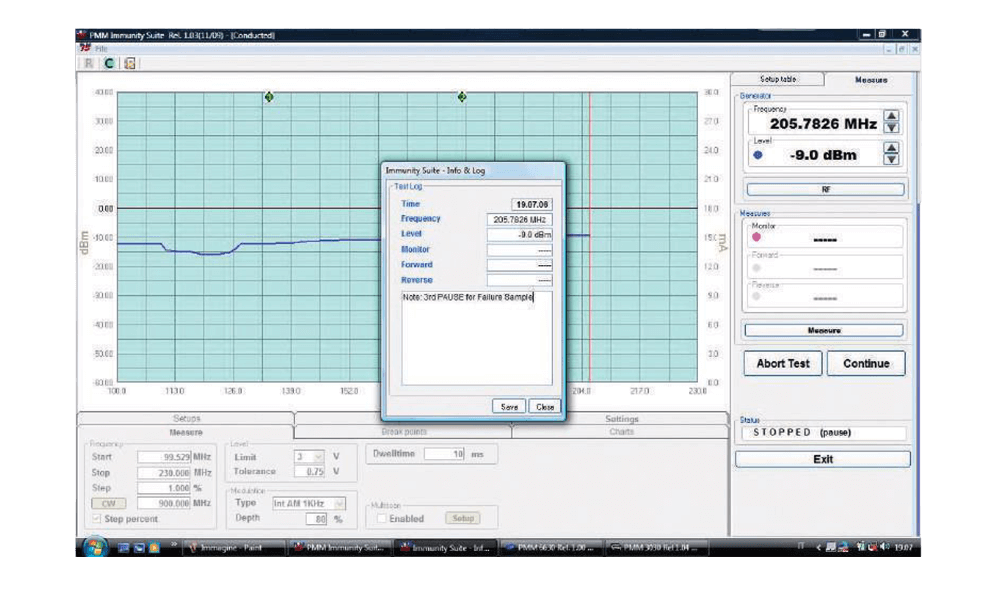

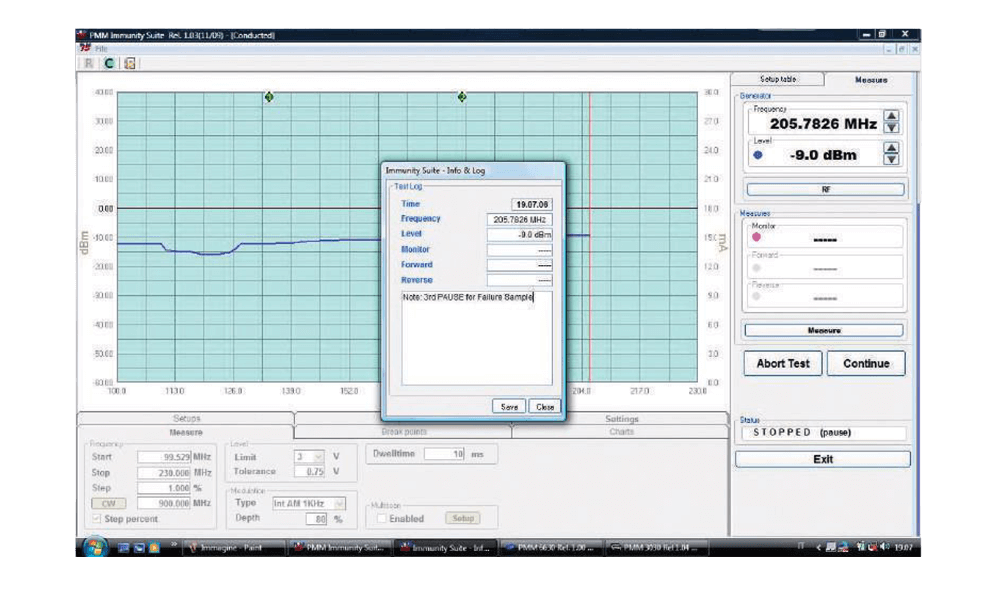

PIMS Immunity Suite - professional software included for free

The PMM Immunity Suite (PIMS) is one of the strongest differentiators of the COND-IS/10.

The PIMS Immunity Suite is designed explicitly for EMC Immunity applications and can handle all essential operations for both calibration and testing with various devices (including CDNs, EM Clamps, Current Injection Clamps, and others used for radiated Immunity).

Software highlights:

- Full automation of testing and calibration

- Control of every PMM generator, amplifier, power sensor and clamp

- Real-time monitoring graphs

- Automatic report generation

- Debug modes (breakpoints, manual tuning, multi-scan optimisation)

- Supports radiated immunity as well as conducted immunity

- Forever free

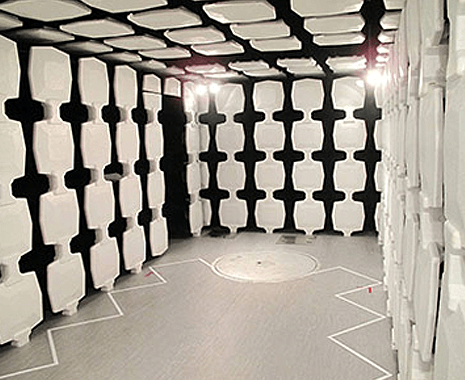

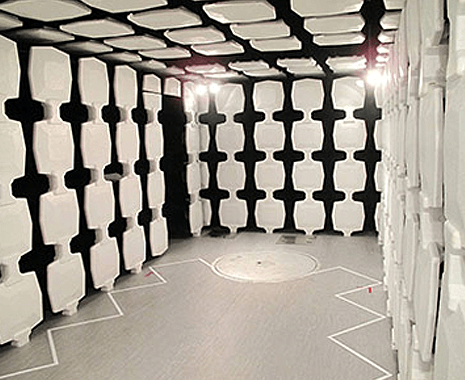

PIMS Immunity Suite is also designed to conduct radiated immunity tests according to IEC/EN 61000-4-3 in both Semi-Anechoic Chambers or TEM/GTEM Cells. It includes calibration of the radiated field up to 16 points in a grid to ensure field uniformity.

Extensive accessory ecosystem (available separately)

We offer a wide range of optional accessories compatible with the COND-IS/10. This ensures the system can adapt to evolving product designs or future regulatory requirements.

Clamps & probes

- Injection clamps (various diameters)

- Decoupling networks for clamps

- EM clamps

- Current monitoring probes

- Complete calibration jigs and fixtures

Additional CDNs

- Single-phase mains

- Three-phase mains

- Balanced & unbalanced telecom lines

- Shielded lines

- Special custom CDNs on request

Calibration & power measurement

- PMM 6630 USB RF Power Meter

- 150 Ω / 50 Ω matching adapters

- Calibration kits for each probe/clamp type

Who should choose the COND-IS/10?

This system is ideal for:

- Manufacturers building in-house EMC immunity labs

- Test houses seeking a scalable EN 61000-4-6 solution

- Defence, avionics and automotive labs using multiple injection methods

- R&D teams needing repeatable, traceable immunity data

- Any organisation wanting a single unified ecosystem instead of mismatched components

Did You Know?

One of the most common failure points when it comes to Bulk Current Injection testing is due to cable leakage. This is due to the injected RF current escaping the cable, coupling to other circuits. To avoid this, engineers need to ensure they have adequate cable shielding, filtering and grounding to avoid these easy but unnecessary failures.

It is recommended conducted immunity testing is performed in a shielded room to prevent data leakage along with the common occurring failures:

- Data loss, packet errors, communication dropouts

- Resets, watchdog triggers

- Flickering displays

- Ethernet/USB/UART desynchronisation

- Sensor misreads or analogue drift

- Relay misfires

Preserve in-house test integrity with APC

Bulk current injection introduces high RF currents onto cables and even though CDNs and clamps provide decoupling, the cables on the EUT side can still behave like efficient antennas. This “leakage” can radiate into the surrounding environment and interfere with nearby equipment or distort your results, especially above 80 MHz or when testing large EUTs with long cable harnesses.

For this reason, many engineers choose to perform EN 61000-4-6 conducted immunity testing inside a shielded room, a Faraday cage or an RF tent. A controlled enclosure prevents unwanted re-radiation, avoids test-site contamination and ensures that injected currents stay on the intended cables rather than coupling into surrounding electronics.

Below are some examples of how APC can support you with your test setup and equipment requirements to fit your long-term testing needs.

|

One-time equipment cost |

|

|

Immediate testing, no scheduling |

|

|

Test immediately after every design change |

|

|

Real-time, unlimited |

|

|

Controlled and repeatable |

|

|

Development, troubleshooting and pre-compliance |

Test Environment Solution

The SpaceSaver™ 26H is an RF-shielded semi-anechoic chamber providing a multi-purpose environment for radiated immunity and pre-compliant emission testing. This compact chamber provides an anechoic test environment that supports testing up to 40 GHz with anechoic performance equal to or better than that required for radiated immunity testing per most standards, including IEC, pre-compliant emission testing, and design and debugging applications.

Having this facility in-house is an incredibly valuable R&D tool. Engineers have faced significant frustration booking a test house to perform pre-compliance EMC testing only for their EUT to fail and the booked slot come to an end.

With an in-house facility you have the following benefits:

- Get confidence your product will pass when you take it to a certified test house for final sign-off

- You set the schedule for the utilisation of the chamber

- R&D facility that doesn’t have to compete with other customer projects

- Return on investment very quick when you factor in expensive test slots at certified EMC test house

Why choose APC for your chamber installation?

- EMC engineers will help you specify and kit out your facility

- Expert installation teams with experience installing state-of-the-art test facilities around Europe

- Scalable and upgradable solutions to match your budget

EMC radiated, conducted & immunity testing categories

Get expert advice

Request a callback from a member of our technical team to get dedicated one-to-one consultancy for Conducted Immunity Testing, in-house capability and compliance.

Ready to bring EMC testing in-house?

Whether you're starting from scratch or upgrading an existing test area, APC supplies the full ecosystem of equipment you need to run EMC testing in-house.

From bespoke test chambers to test and measurement equipment and RF systems, APC work with customers directly to reduce outsourcing costs, shorten development cycles and gain full control over pre-compliance testing.

Your partner for reliable and compliant EMC testing solutions

With 40+ years of expertise supporting the electronics industry, APC provides high-reliability components, test equipment and engineering support for organisations building or expanding their EMC and test capabilities. As an authorised distributor for 100+ specialist manufacturers, we supply genuine, traceable equipment backed by recognised certifications.

Related test standards:

International Standard: IEC 61000-4-6

British Standards Institution: EN 61000-4-6

Conducted Immunity Frequently Asked Questions (FAQs)

What are the levels of conducted immunity test?

Conducted immunity test levels, primarily defined by EN/IEC 61000-4-6, involve applying modulated RF signals to power and I/O cables at varying voltage levels (e.g., 1V, 3V, 10V, or custom 'X') across a frequency range (typically 150 kHz to 80 MHz) to check product performance against electromagnetic disturbances, with higher levels indicating harsher environments like industrial zones.

What is the difference between radiated noise and conducted noise?

Noise is classified into radiated and conducted noise according to the path it travels. Radiated noise is transmitted through space, while conducted noise is physically transmitted through electronic circuits and cables.

What is the difference between conducted and radiated emission?

Unlike conducted EMI, radiated EMI requires no physical contact; it travels through the air instead. These emissions happen when devices produce intentional or unintentional electromagnetic energy in the form of an electrical field.