Radiated Emissions Testing for EMC Compliance

Antenna selection, chamber requirements and class A/B limits for RF emissions measurement

Radiated emissions testing is by far the most common Electromagnetic Capability (EMC) test conducted worldwide. Every major market has radiated emission limits that apply, regardless of product type or industry.

In this guide, we will explore what radiated emissions are, how they are tested, the specialised environments they are tested in and the requirements for radiated emissions defined in EN 55032 and the methodology and equipment according to CISPR 16.

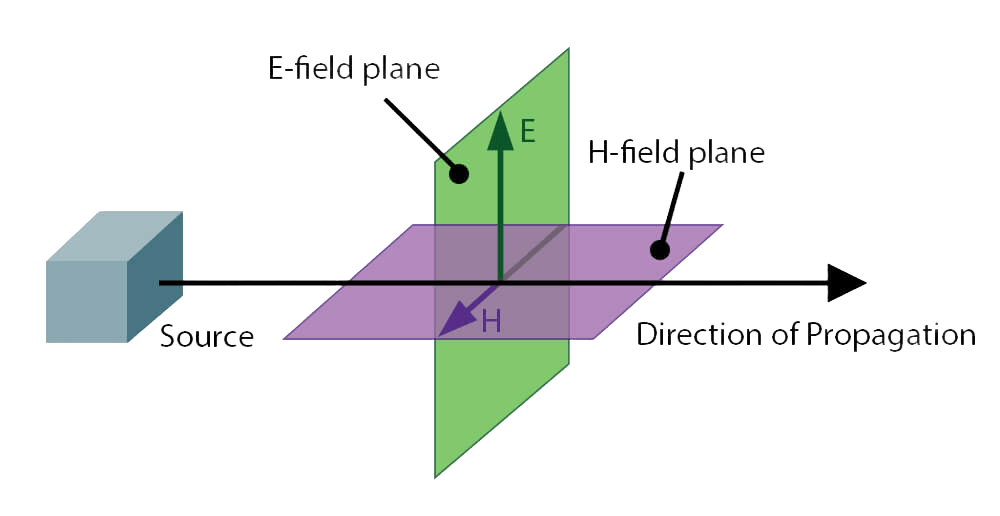

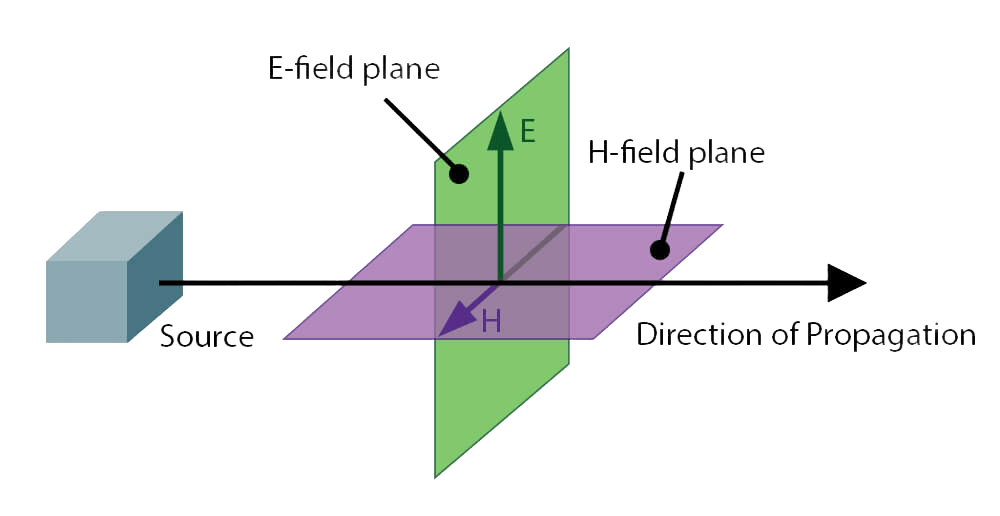

What are radiated emissions?

Radiated emissions are electromagnetic fields unintentionally emitted by electronic devices. Unlike conducted emissions, which travel along cables, radiated emissions travel through the air and can interfere with receivers, communications systems and safety-critical electronics.

Where radiated emissions come from:

- Switching power supplies

- Fast digital edges

- PWM motor drives

- Long harnesses acting as antennas

- Mode conversion from conducted noise

Why radiated emissions testing matters

Radiated emissions impact actual products in real-world settings. High emission levels can compromise or disable vital functionalities due to excessive electromagnetic energy, posing safety risks and causing widespread interference with other devices.

Uncontrolled radiated emissions pose significant safety risks, particularly in applications within the Critical National Infrastructure (CNI). Examples of which are below:

Defence

Applies to military systems, equipment and subsystems on ships, aircraft and ground vehicles, including COTS equipment. (MIL-STD-461/G - RE101 & RE102)

Medical

Applies to the safety and performance of medical electrical equipment and systems amidst EM disturbances and to disturbances emitted by them. (CISPR 11 - EN 60601-1-2)

Aerospace

Applies to safety-critical communication modules, requiring control of RF emissions to prevent EMI with navigation and flight control systems. (RTCA DO 160 Section 21)

Intentional vs unintentional radiation

Intentional radiated emissions

Devices specifically designed to generate and emit radio frequency (RF) energy for communication or other purposes, such as smartphones, Wi-Fi routers, Bluetooth devices and radio transmitters.

Unintentional radiated emissions

Devices that internally use or generate energy (e.g. in digital circuits or switching power supplies) but are not intended to radiate that energy into the environment as a primary function. These can be anything from computers, digital cameras, power supplies and most general electronic devices.

How are radiated emissions measured?

Radiated emissions are measured in specialised facilities like Semi-Anechoic Chambers (SAC) or Open Area Test Sites (OATS) using specific equipment such as antennas, EMI receivers and a turntable to ensure the emissions from a device under test (DUT) fall within regulatory limits.

Test environments:

- Open Area Test Site (OATS)

- Semi-Anechoic Chamber (SAC)

The ideal test environment would be an OATS with an infinite half-space above the ground plane, free from RF noise. Due to global connectivity, these spaces are increasingly rare and far from civilisation, which is why a test facility like the SAC is used to simulate this environment. A SAC can isolate signals from external interference and create a controlled space where disturbances can be measured as they propagate in a uniform manner.

Open Area Test Sites (OATS)

Open Area Test Sites (OATS) are vital for dependable EMC and emissions testing of large equipment. These sites provide a flat, open space with a conductive ground plane, designed to be free from external signal interference and reflective objects.

This controlled environment reduces signal distortions, which are common in enclosed spaces, resulting in consistent measurements.

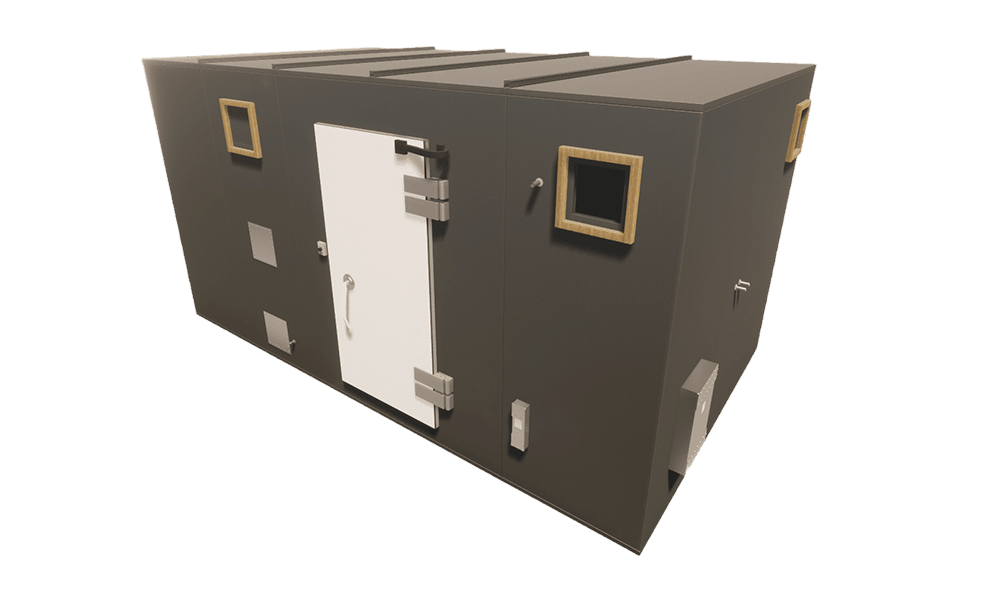

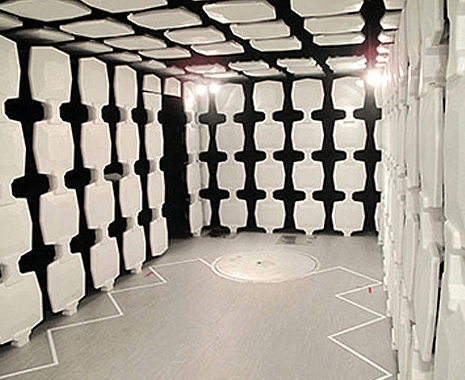

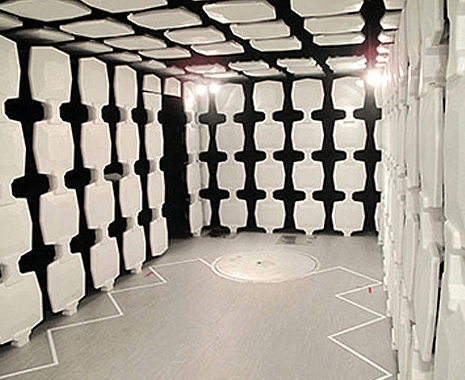

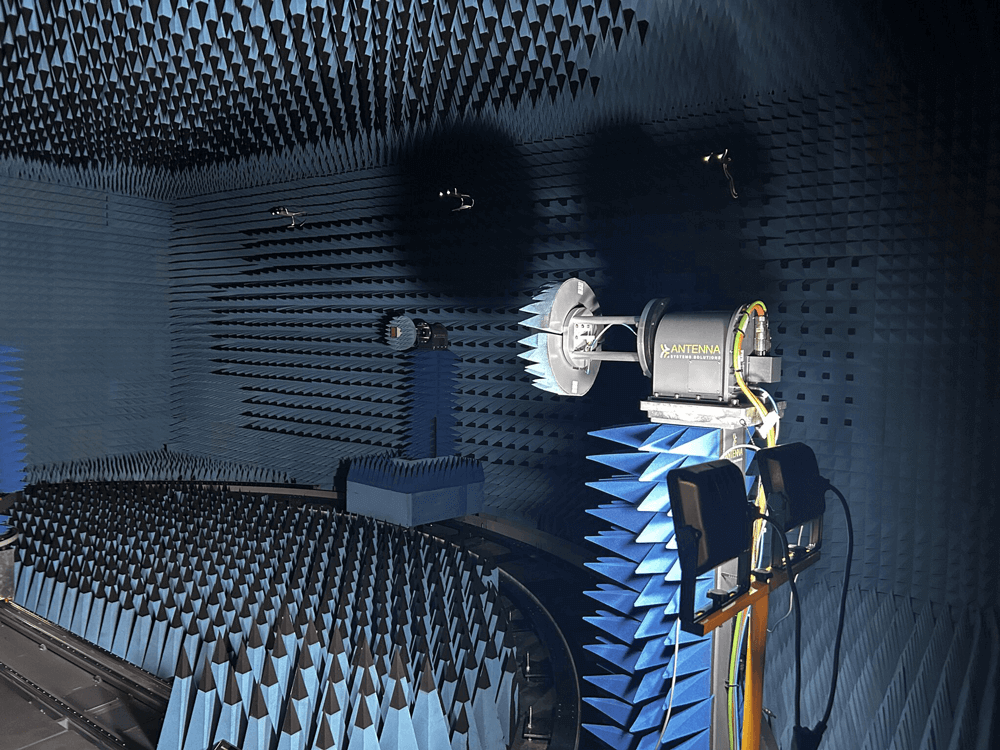

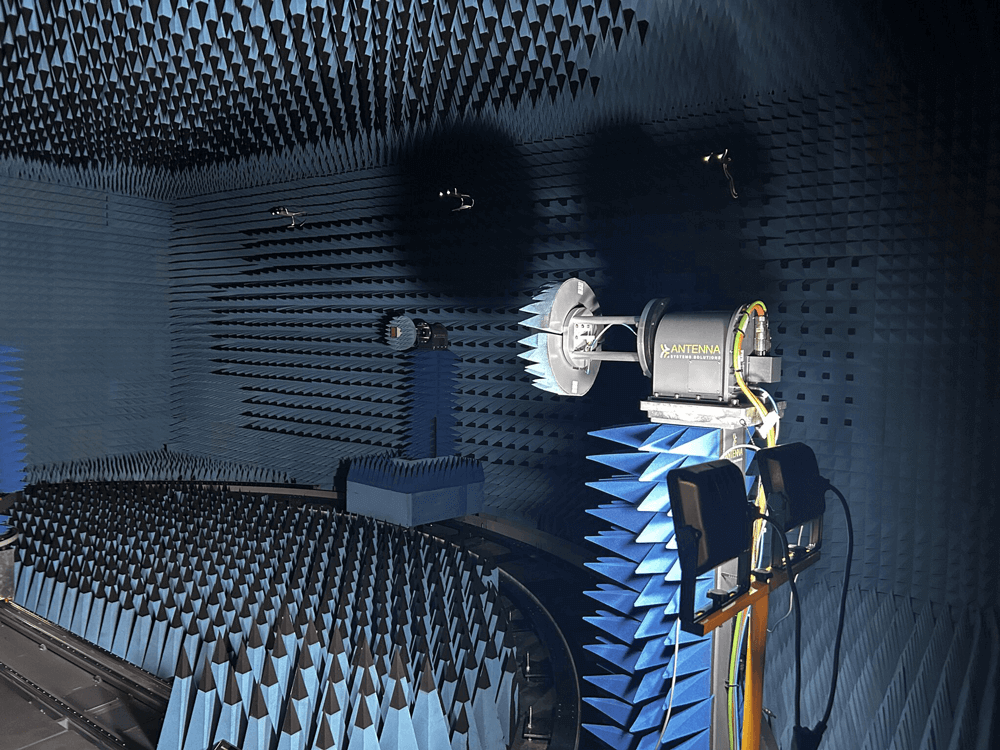

Semi-Anechoic Chambers (SAC)

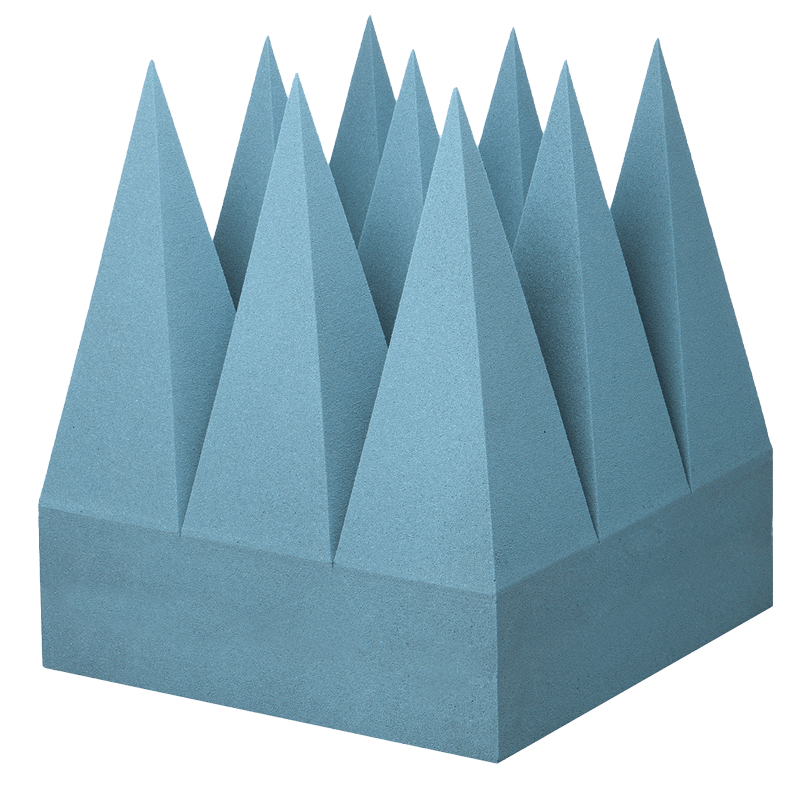

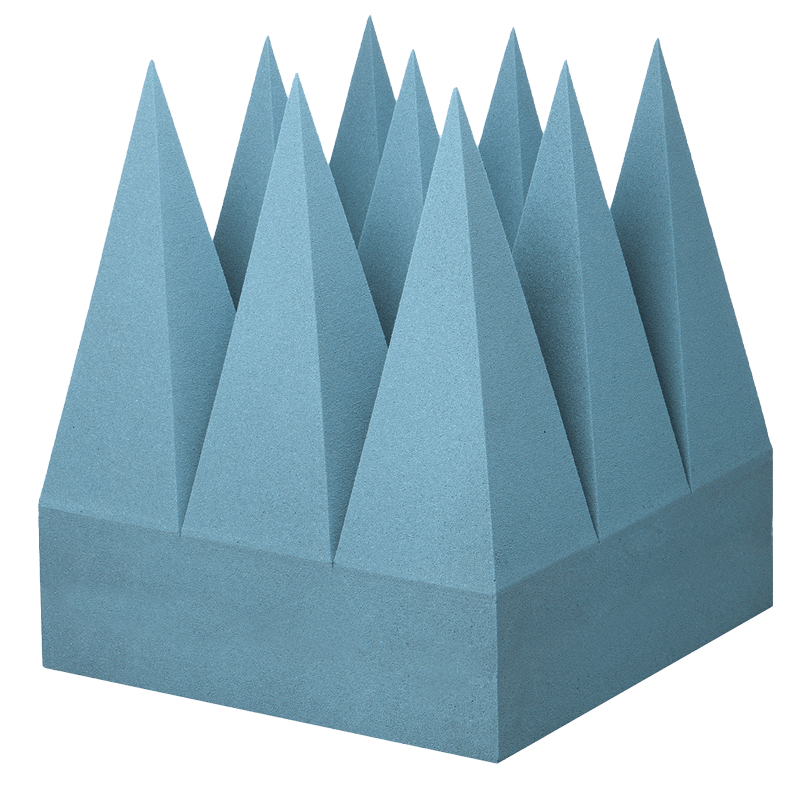

The most widely used environment for testing radiated emissions is a semi-anechoic chamber, due to their advanced RF-absorbing materials. These chambers combine cone shaped radiation-absorbent material (RAM) and conductive ferrite tiles on the walls and ceiling to absorb RF energy, simulating that open space environment.

This setup ensures high measurement repeatability, stable electromagnetic behaviour and strong rejection of external interference, making them the preferred choice for certification testing.

Test environment solution

The SpaceSaver™ 26H is an RF-shielded semi-anechoic chamber providing a multi-purpose environment for radiated immunity and pre-compliant emission testing. This compact chamber provides an anechoic test environment that supports testing up to 40 GHz with anechoic performance equal to or better than that required for radiated immunity testing per most standards, including IEC, pre-compliant emission testing, and design and debugging applications.

Having this facility in-house is an incredibly valuable R&D tool. Engineers have faced significant frustration booking a test house to perform pre-compliance EMC testing only for their Equipment Under Test (EUT) to fail and the booked slot come to an end.

With an in-house facility, you have the following benefits:

- Confidence that your product will pass when you take it to a certified test house for final sign-off

- You set the schedule for the utilisation of the chamber

- An R&D facility that doesn’t have to compete with other customer projects

- Return on investment is very quick when you factor in expensive test slots at a certified EMC test house

Why choose APC for your chamber installation?

- EMC engineers will help you specify and kit out your facility

- Expert installation teams with experience installing state-of-the-art test facilities around Europe

- Scalable and upgradable solutions to match your budget

Learn more about the RF absorbers, ferrite tiles, doors and waveguide vents and anechoic chamber components APC Technology Group supplies from leading EMC manufacturers to support compliant, high-performance test environments.

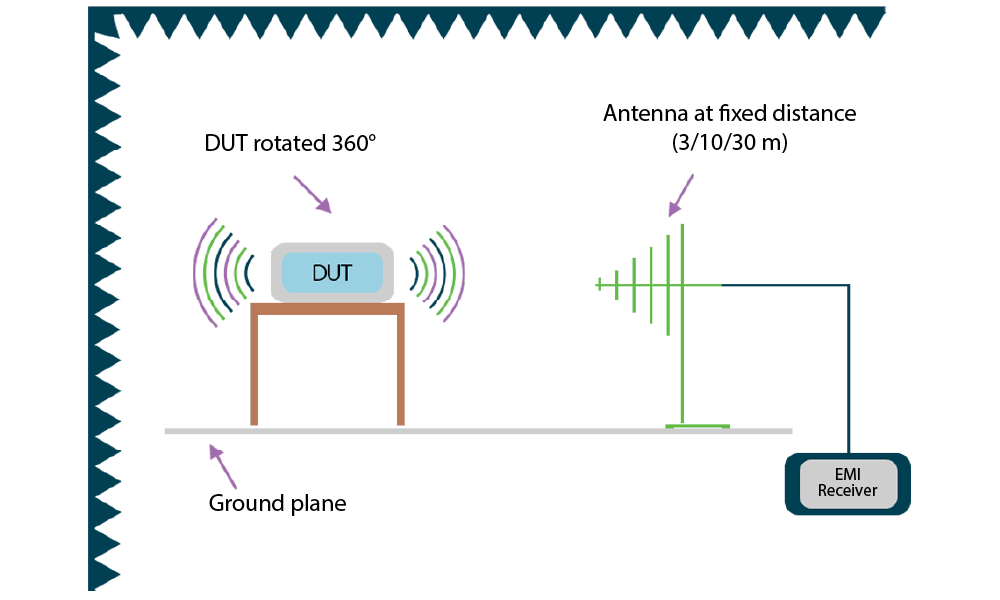

Radiated emissions test procedure

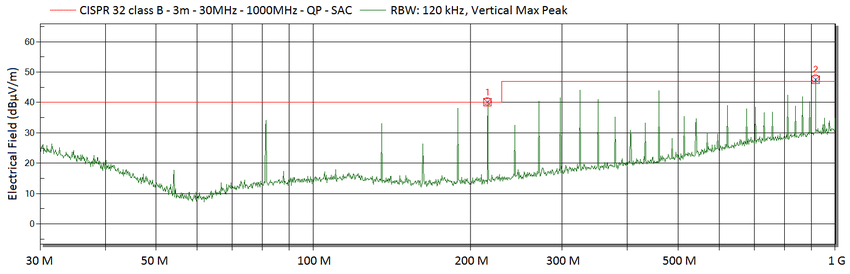

During a radiated emissions test, the EUT is placed on a non-conductive table mounted above a ground plane or turntable. A calibrated antenna is positioned at a fixed distance, typically 3 m or 10 m, with its height swept between 1 m and 4 m to capture maximum field strength. The turntable then rotates the EUT through 360° whilst an EMI receiver scans the required frequency range using the Quasi-Peak detector. Any emission peaks found during the sweep are compared against the applicable limit lines.

Measurement overview:

- EUT placed on a turntable or table on a ground plane

- Calibrated measurement antenna at fixed distance (3/10/30 m)

- Antenna height swept (1–4 m)

- EUT rotated 360°

- EMI receiver sweeps full band with QP detector

Antennas used in radiated emissions testing

Radiated emissions testing relies on calibrated, broadband antennas to detect the electromagnetic energy unintentionally emitted by electronic equipment. Because no single antenna can efficiently cover the full CISPR 16 radiated emissions frequency range, test labs use multiple antenna types, each optimised for a different portion of the spectrum.

The choice of antenna directly affects measurement sensitivity, noise floor and repeatability, which is why CISPR requires antennas with known correction factors and traceable calibration.

The three antenna families most commonly used in radiated emissions are:

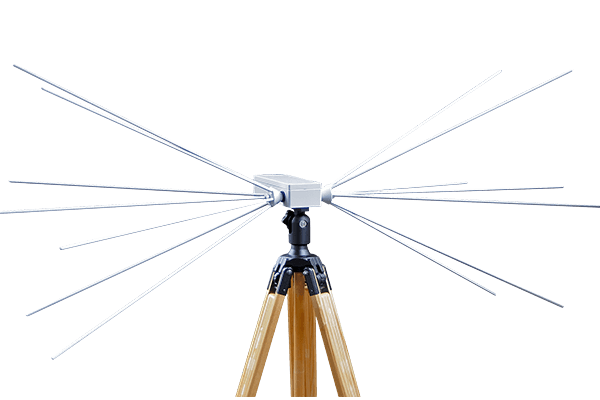

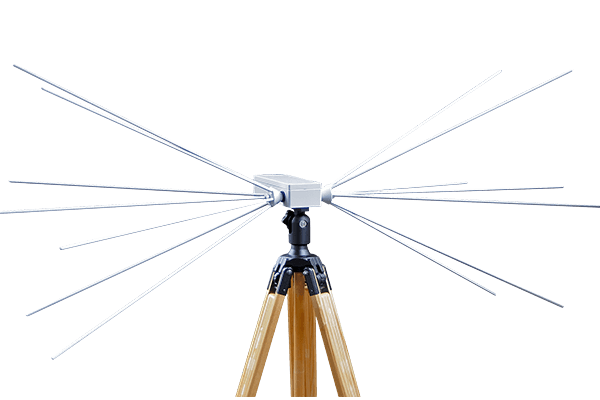

- Biconical antennas (ideal for 20 - 300 MHz)

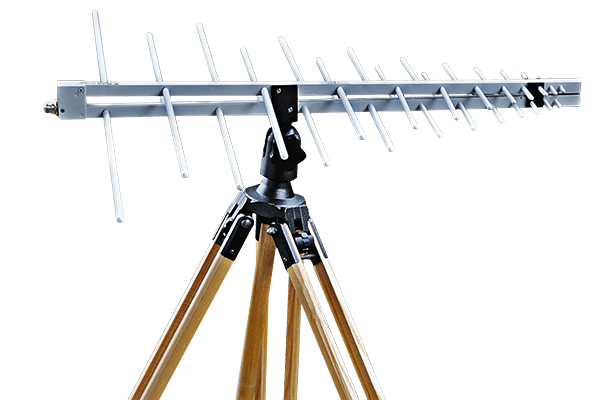

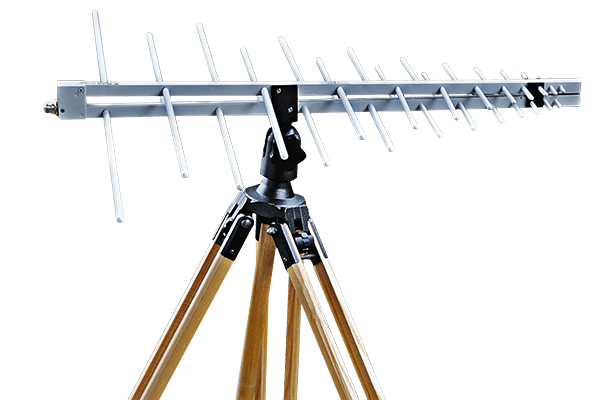

- Log-periodic antennas (ideal for 300 MHz - 1 GHz)

- Horn antennas (used above 1 GHz, often for pre-compliance below 1 GHz)

Biconical

Frequency: 30 MHz to 200 MHz

Log Periodic

Frequency: 200 MHz to 3 GHz

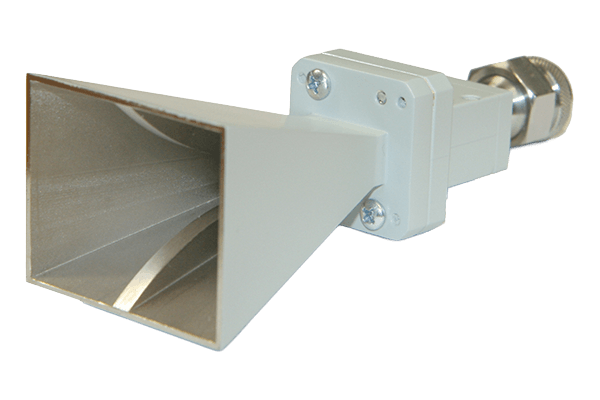

Horn

Frequency: 6 GHz to 18 GHz

When each antenna is used

- Biconical Antennas: preferred for low-frequency radiated emissions (typically 20 - 300 MHz) where long cable structures and power systems dominate the noise

- Log-periodic Antennas: take over at mid-to-high frequencies (300 MHz - 1 GHz) where digital clocks, microprocessors and high-speed interfaces produce harmonics

- Horn Antennas: provide high sensitivity and directionality above 1 GHz, helping identify emissions from Wi-Fi chipsets, switching regulators and RF-dense electronics

Together, these antenna types ensure complete CISPR 16 compliance across the regulated radiated emissions spectrum.

What are the emission limits and frequency ranges?

The limits vary significantly based on frequency and the classification of the equipment (e.g. Class A or Class B), with common units being dBµV/m for electric field strength.

The allowable limit for RF emissions from an EUT can vary depending on how protected the band is. For example, frequency bands reserved for communication systems will have a lower limit line so the EUT doesn’t interfere with the communication signals.

Frequency ranges explained

- Common range: 30 MHz to 1 GHz is a common frequency range for many commercial standards, like CISPR 32

- Higher ranges: Testing can extend to 6 GHz and beyond, especially based on the highest clock frequency of the device under test (DUT)

- FCC regulations: The FCC's testing range can extend up to 40 GHz, depending on the device's clock frequency

Emission limits Class A vs Class B

The limits in radiated emission tests come under ‘Class A and Class B’. Both classes represent different operating environments, with Class A being for industrial or commercial settings and Class B being for residential/domestic environments. Class B limits are much stricter because residential areas have more sensitive equipment, making them harder to achieve.

Class A = everywhere else (higher limits, easier to meet)

Class B = domestic/residential (lower limits, harder to meet)

A breakdown of each is defined below:

|

Feature |

Class A |

Class B |

|

Intended environment |

Commercial and industrial establishment |

Residential, commercial and light industrial environments |

|

Emission limits |

Higher limits (less strict) |

Lower limits (stricter) |

|

Compliance |

Easier to meet |

Hard to meet |

|

Reasoning |

Assumes a more robust RF environment where higher levels of interference are tolerated |

Assumes a sensitive environment where interference is required |

Build a fully-compliant radiated emissions test system with APC Technology Group

Modern radiated emissions compliance requires more than standalone test equipment. Engineers need a complete measurement ecosystem that delivers repeatability, accuracy and seamless integration into Anechoic Chambers or Open Area Test Sites (OATS).

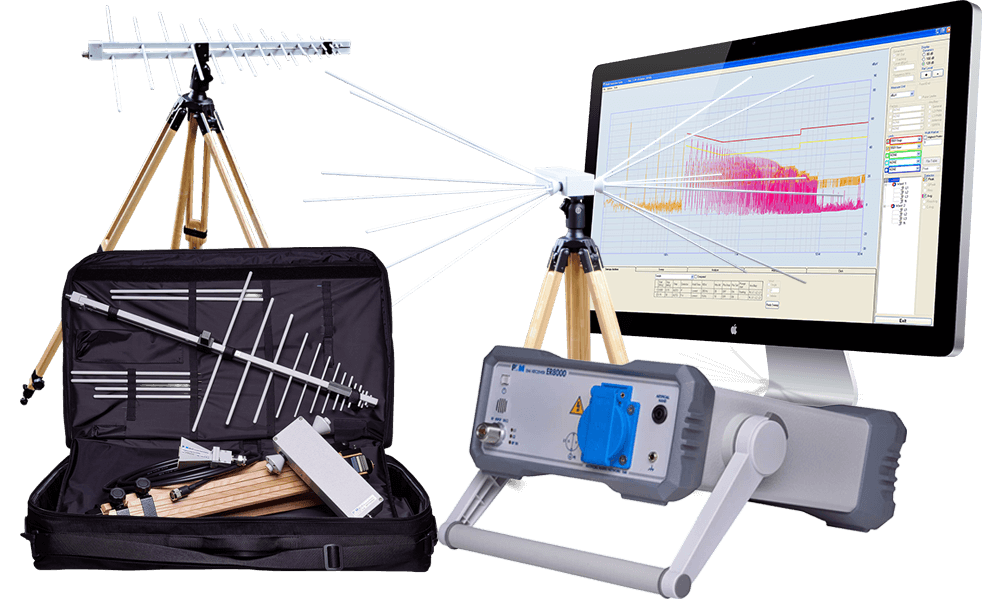

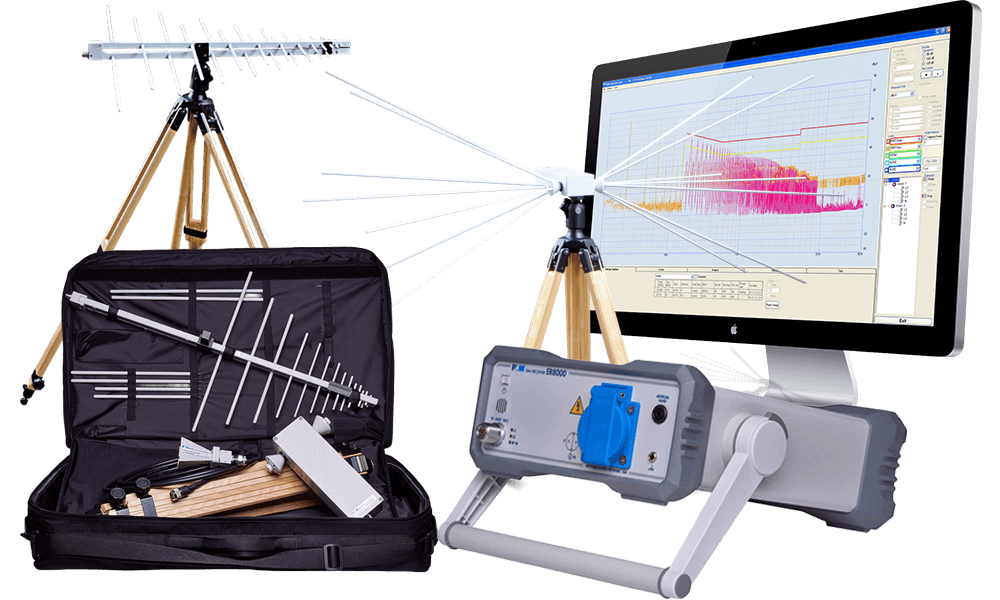

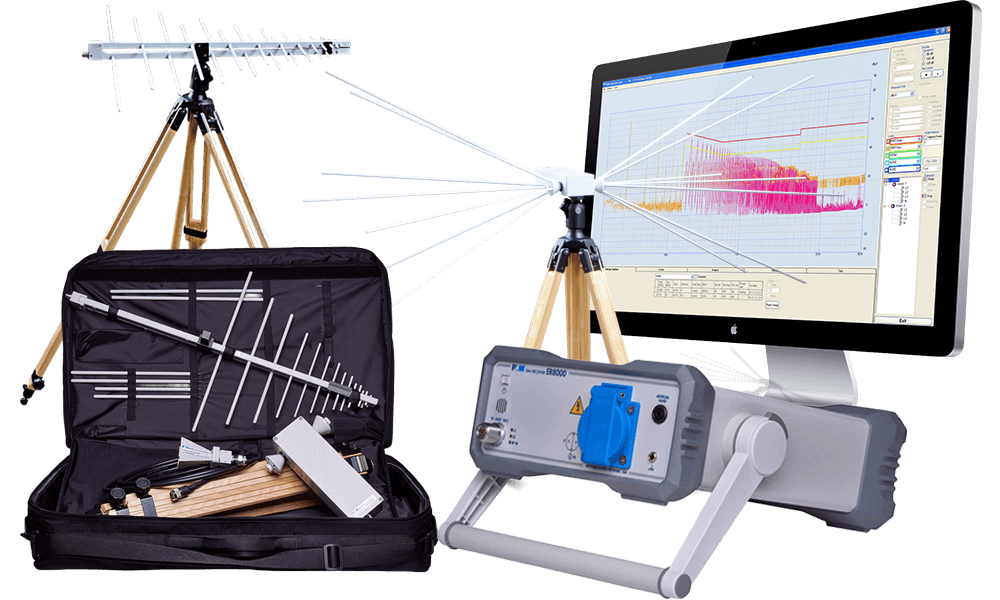

APC offers a series of radiated-emission test equipment bundles designed to support both pre-compliance and full-compliance workflows. These three bundles provide everything needed for Class A/B radiated emissions, pre-compliance and full-compliance test workflows from 9 kHz up to 3 GHz.

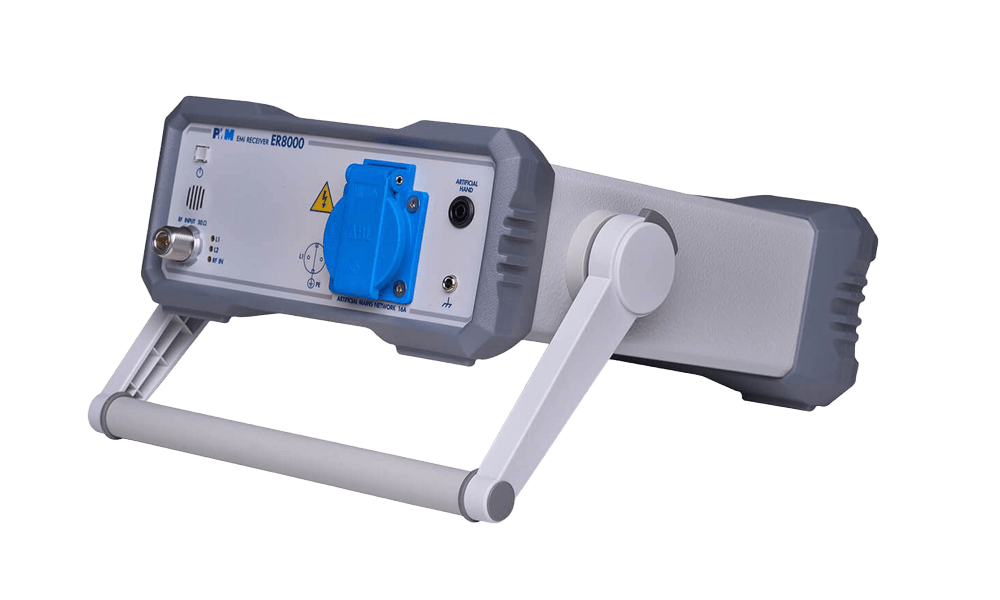

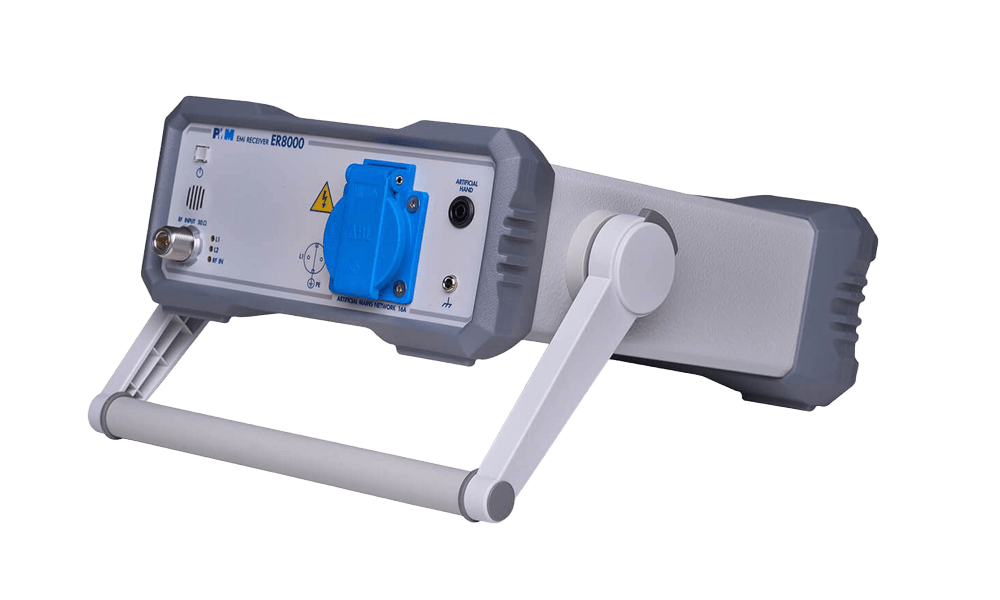

Bundle 1 - EMI receiver (9 kHz - 30 MHz) with internal LISN

Ideal for: Conducted emissions, low-frequency radiated emissions support and pre-compliance labs.

Bundle highlights:

- FFT EMI Receiver with LISN

- CISPR 16-1-1 full compliance 9 kHz - 30 MHz

- MIL STD 6 dB RBW IF filters from 100 Hz to 3 MHz

- Internal LISN 230 VAC - 16A, full compliance 150 kHz - 30 MHz

Standard accessories:

- AC/DC converter with plug adapters

- AC cable for internal LISN

- PES Emission Suite

- USB, RS-232 cables

- USB/RS-232 serial converter

- N (m) - BNC (f) Adapter

- Soft Accessory Pocket

- Ground Connection Kit

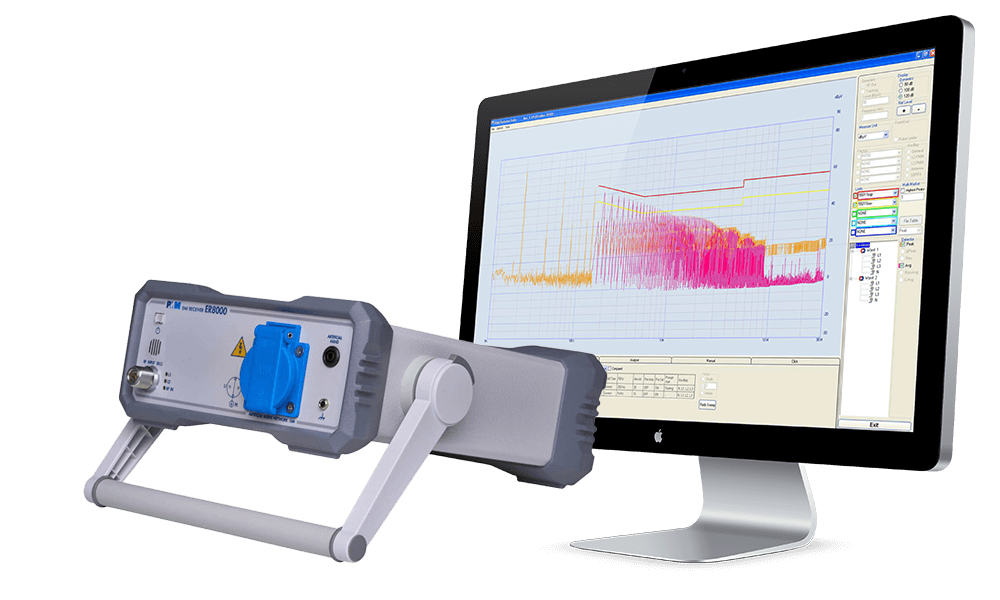

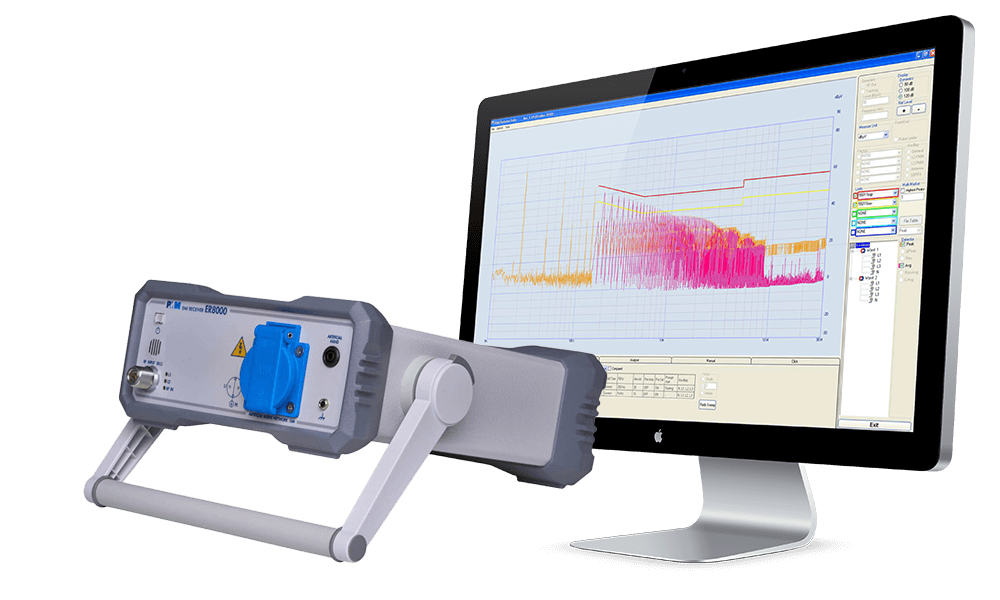

Bundle 2 - EMI receiver (9 kHz–3 GHz) with internal LISN

Ideal for: Full radiated emissions measurement, Class A/B equipment, OATS and chamber testing. Bundle 2 allows expanded measurement capability up to 3 GHz, covering the entire CISPR radiated emissions band. This bundle also supports quasi-peak, average, peak detection, MIL-STD IF bandwidths and integrates directly into an EMC chamber environment.

Bundle highlights:

- Extended frequency range to 3 GHz

- Full radiated-emissions detector set (QP, AVG and PK)

- Higher-band measurement capability for modern digital equipment

- Chamber-ready calibration profiles

Standard accessories:

- AC/DC converter with plug adapters

- AC cable for internal LISN

- PES Emission Suite

- USB, RS-232 cables

- USB/RS-232 serial converter

- N (m) - BNC (f) Adapter

- Soft Accessory Pocket

- Ground Connection Kit

Bundle 3 - EMI receiver including AS-02 antenna set (Biconical & Log-Periodic)

Ideal for: Full turnkey radiated-emissions test capability from 30 MHz to 3 GHz.

Pair the 9 kHz - 3 GHz receiver with a fully calibrated antenna set for sweeping the entire RE band:

- BC-01 Biconical antenna: 30 to 200 MHz

- LP-02 Log-periodic antenna: 200 to 3 GHz

The result is a complete radiated-emissions test chain ready for use in a chamber or OATS environment.

Everything in bundle 2 plus:

- AS-02 calibrated antenna set, including 2 antennas (30 MHz to 3 GHz):

- BC-01 Biconical Dipole

- LP-02 Log Periodic Dipole Array

- Calibration certificates

- Antenna mounts and adaptors

Standard accessories:

- AC/DC converter with plug adapters

- AC cable for internal LISN

- PES Emission Suite

- USB, RS-232 cables

- USB/RS-232 serial converter

- N (m) - BNC (f) Adapter

- Soft Accessory Pocket

- Ground Connection Kit

Everything CISPR 16 In One Box

These three turnkey bundles provide everything needed for Class A/B radiated emissions test workflows from 9 kHz up to 3 GHz. These bundles can be altered according to your radiated emission test requirements. Whether you’re looking to change an antenna of a specific add-on, contact our team of EMC experts today.

Compare which bundle is right for your radiated emissions test setup

|

Feature |

Bundle 1 |

Bundle 2 |

Bundle 3 |

|

Frequency range |

9 kHz - 30 MHz |

9 kHz – 3 GHz |

9 kHz – 3 GHz |

|

Conducted emissions |

|

|

|

|

Radiated emissions |

Limited |

Full |

Full |

|

Antennas included |

|

|

|

|

Internal LISN |

|

|

|

|

Chamber/OATs ready |

Partial |

|

|

Common causes of radiated emission failures and pitfalls

One of the most persistent challenges in radiated emissions testing is common-mode noise coupling onto external cables, causing them to act as unintended antennas. This is a leading cause of failures across many products, particularly in the 30 - 300 MHz range where cable structures radiate most efficiently. Because common-mode emissions are highly sensitive to cable routing, ground-plane height and surrounding reflections, measurements often vary between facilities or even between tests in the same environment.

As a result, engineers frequently struggle to reproduce failures once they leave an accredited chamber or OATS, making debugging slow, inconsistent and costly. These difficulties highlight the importance of having a stable, repeatable in-house radiated emissions test environment. Establishing a controlled test environment early in the process allows teams to identify issues sooner, validate fixes with confidence and reduce reliance on external test labs.

This is where APC Technology Group’s complete EMC ecosystem supports engineering teams. From early-stage design considerations to fully equipped chambers, compliant test equipment, installation and long-term support, APC provides a turnkey pathway to building reliable in-house EMC capability. By working closely with industry-leading EMC solution providers, APC’s Test Solutions team offers practical, first-hand technical support to help customers overcome EMC challenges and achieve reliable first-time compliance.

Case Study

Enabling precision electromagnetic research: APC’s custom chamber for the University of Birmingham

APC Technology Group partnered with the University of Birmingham, which required a fully customised anechoic chamber capable of supporting advanced antenna and electromagnetic measurement.

Working closely with UoB’s research teams, we delivered a precision-engineered full anechoic facility designed to operate from 1 GHz all the way to 330 GHz, enabling:

- Far-field (FF) antenna measurements

- Spherical near-field (SNF) characterisation

- Monostatic and bistatic electromagnetic scattering measurements

The same engineering expertise behind this advanced academic chamber is available for organisations seeking their own semi-anechoic or fully anechoic chamber for radiated or conducted emissions testing environments.

For organisations needing a compliant, high-performance chamber for radiated or conducted emissions testing, APC provides tailored design, supply and integration support.

Bring radiated emissions testing in-house with APC

Below are some examples of how APC can support you with your test setup and equipment requirements to fit your long-term testing needs.

|

One-time equipment cost |

|

|

Immediate testing, no scheduling |

|

|

Test immediately after every design change |

|

|

Real-time, unlimited |

|

|

Controlled and repeatable |

|

|

Development, troubleshooting and pre-compliance |

Browse our full range of EMC test equipment, anechoic chambers, faraday cages & shielded Rooms

Get expert advice

Request a callback from a member of our technical team to get dedicated one-to-one consultancy for Radiated Emissions Testing, in-house capability and compliance.

Ready to bring EMC testing in-house?

Whether you're starting from scratch or upgrading an existing test area, APC supplies the full ecosystem of equipment you need to run EMC testing in-house.

From bespoke test chambers to test and measurement equipment and RF systems, APC work with customers directly to reduce outsourcing costs, shorten development cycles and gain full control over pre-compliance testing.

Your partner for reliable and compliant EMC testing solutions

With 40+ years of expertise supporting the electronics industry, APC provides high-reliability components, test equipment and engineering support for organisations building or expanding their EMC and test capabilities. As an authorised distributor for 100+ specialist manufacturers, we supply genuine, traceable equipment backed by recognised certifications.

Resources for radiated emissions testing for electromagnetic compatibility of multimedia equipment

International: CISPR 32 Consolidated version

UK: BS EN 55032

CISPR 16 Series (Measurement Apparatus and Methods)

Measuring apparatus: CISPR 16-1-1

Antennas and test sites: CISPR 16-1-4

EMC antenna calibration: CISPR 16-1-6

Radiated disturbance measurements: CISPR 16-2-3

Immunity measurements: CISPR 16-2-4

Measurement uncertainty: CISPR 16-4-2

Aerospace, Medical and Military Standards for Radiated Emissions Testing:

Military & Defence Electronics: MIL-STD-461/G - RE101 & RE102

Medical: CISPR 11 - EN 60601-1-2

Aerospace: RTCA DO 160 Section 21

References:

Figure 1: Open Area Test System (OATS), emc-directory.com

Figure 2: Radiated Emissions Test Result (CISPR 32 Class B), community.st.com

Radiated emissions testing - Frequently Asked Questions (FAQs)

What is radiated emissions testing?

Radiated emissions testing measures the electromagnetic energy unintentionally emitted by an electronic device into free space. The test verifies that emissions remain below regulatory limits to prevent interference with nearby equipment and radio services, using standardised measurement methods defined by CISPR and IEC standards.

Why is radiated emissions testing important for EMC compliance?

Radiated emissions testing is required to demonstrate compliance with EMC regulations such as CE marking. Excessive emissions can cause interference with communication systems, control equipment and safety-critical electronics, leading to regulatory failure, product recalls or restricted market access.

What standards apply to radiated emissions testing?

Radiated emissions measurements are performed using CISPR-16, which defines the instrumentation and test methods. Emission limits are specified in product standards such as EN 55032 for multimedia equipment, with other CISPR or IEC standards applying depending on product category.

What is the difference between radiated emissions and conducted emissions?

Radiated emissions refer to electromagnetic energy emitted through the air, typically measured using antennas in open-area or chamber environments. Conducted emissions measure interference travelling along power or signal cables. Most EMC test programmes include both to ensure full emissions compliance.

What frequency range is covered in radiated emissions testing?

Radiated emissions testing typically covers frequencies from 30 MHz to 1 GHz, with higher frequencies tested depending on the product standard and application. The exact range is defined by the applicable CISPR or IEC product standard.

Can radiated emissions testing be done in-house?

Yes. Many organisations perform pre-compliance radiated emissions testing in-house to identify issues early, reduce external lab costs and improve first-time pass rates. In-house setups typically include antennas, receivers, turntables and shielding solutions aligned with CISPR-16 methods.

How do radiated emissions differ from immunity testing like ESD or EFT?

Radiated emissions testing evaluates how much electromagnetic energy a product emits, while immunity testing (such as ESD or EFT/Burst) evaluates how well a product tolerates external disturbances. Both are required for full EMC validation but address different aspects of electromagnetic compatibility.

Is radiated emissions testing required for CE marking?

Yes. Radiated emissions testing is a key requirement for demonstrating compliance with the EMC Directive for CE marking. The applicable emission limits depend on the product type and intended environment, as defined by the relevant harmonised standards.