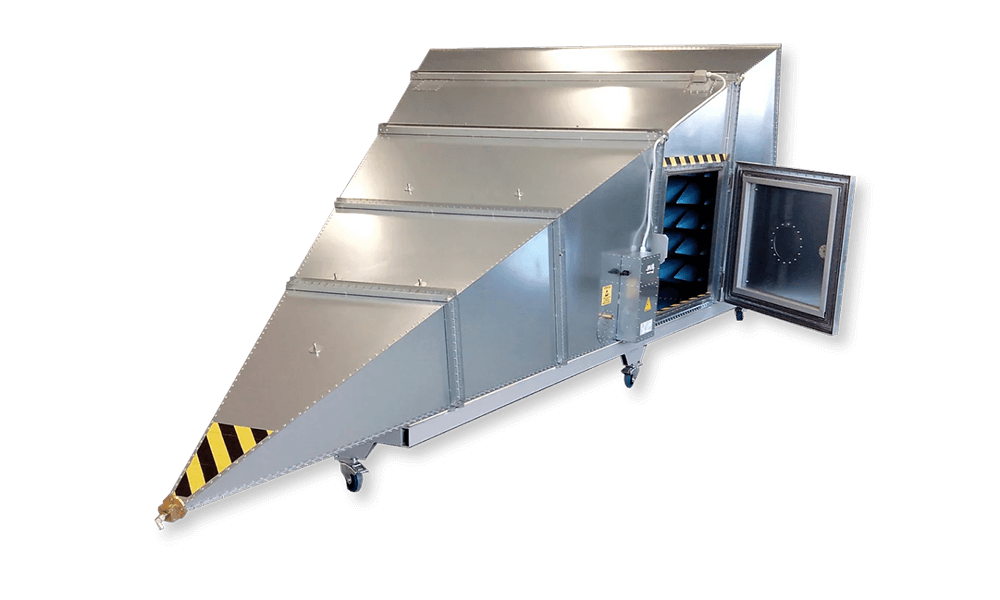

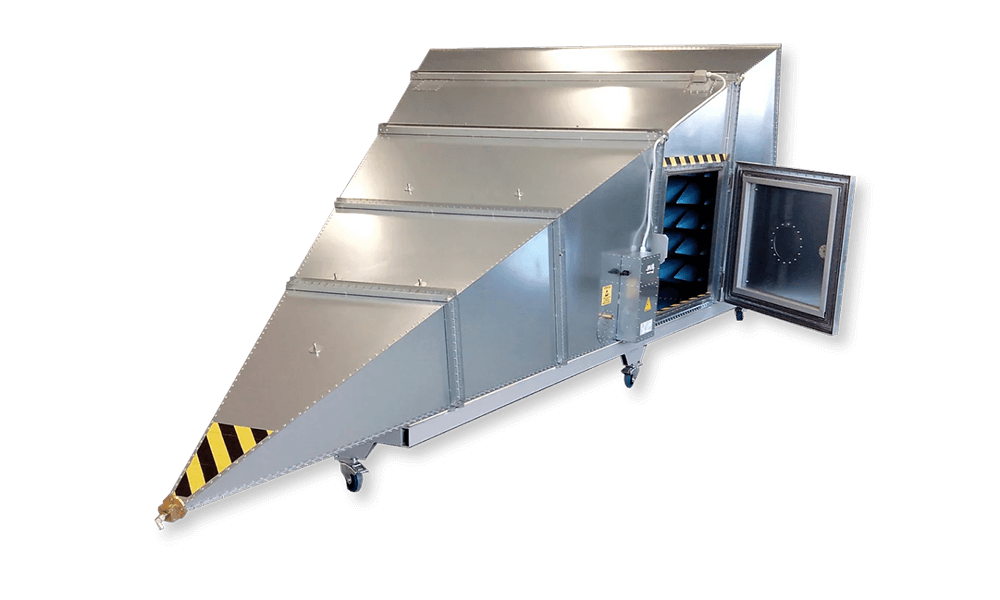

GTEM (Gigahertz Transverse Electromagnetic) Cells / TEM Cells for Radiated Emission & Immunity Testing

A cost-effective and space-saving solution for in-house EMC pre-certification testing

In EMC testing, the ability to carry out accurate and repeatable measurements without long lead times is critical during product development. For many R&D teams, access to a full-scale anechoic chamber can be a limiting factor in terms of cost, space or availability.

GTEM cells (Gigahertz Transverse Electromagnetic Cells) address this challenge by providing a compact, high-performance EMC test environment that supports both radiated emissions and radiated immunity testing, without the footprint or infrastructure demands of a traditional chamber.

What is a GTEM Cell?

A GTEM cell is a controlled EMC test environment designed for testing electronic equipment across a wide frequency range. It offers a shielded and repeatable alternative to open area test sites (OATS) and anechoic or semi-anechoic chambers, making it particularly well-suited to engineering and pre-compliance EMC testing.

By generating a uniform transverse electromagnetic field within a calibrated volume, these cells allow engineers to assess exactly how their products behave in the presence of electromagnetic interference (EMI) under strictly controlled conditions.

How Does a GTEM Cell Work?

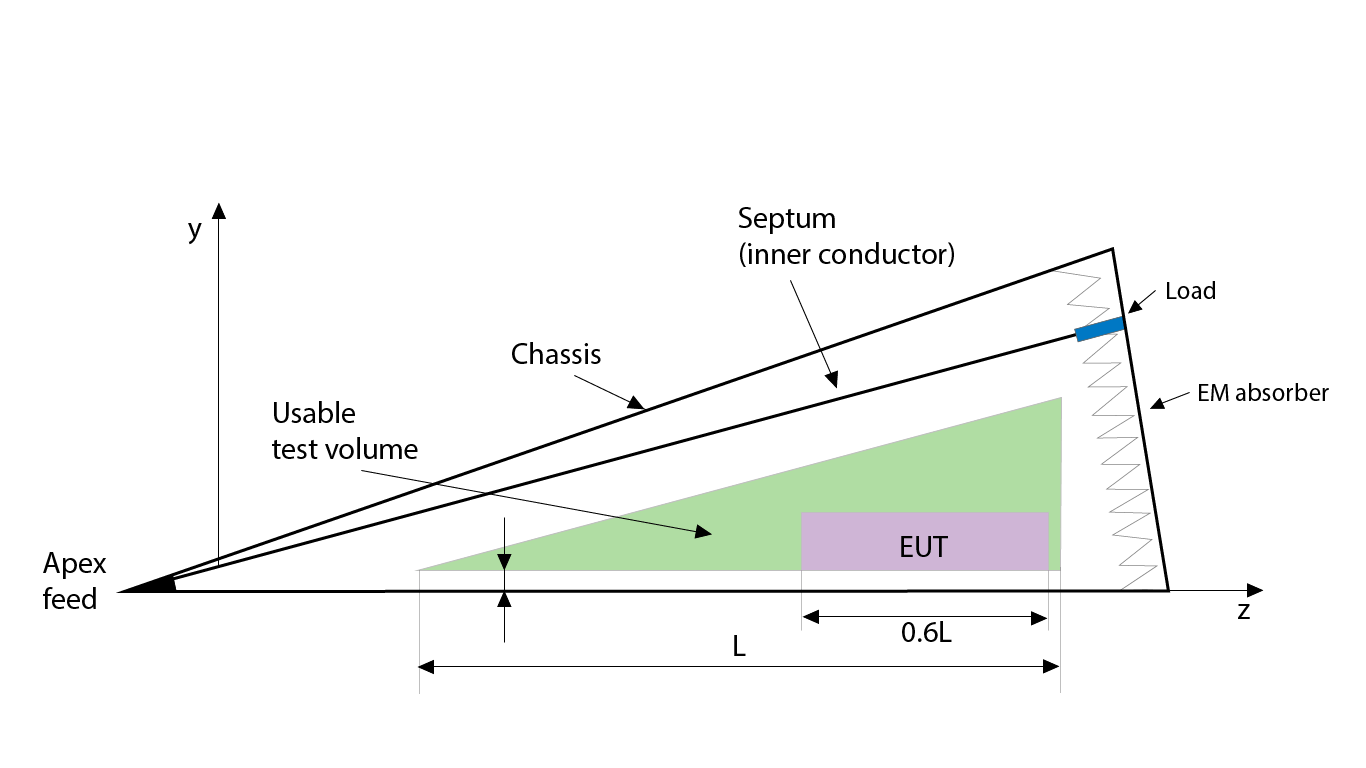

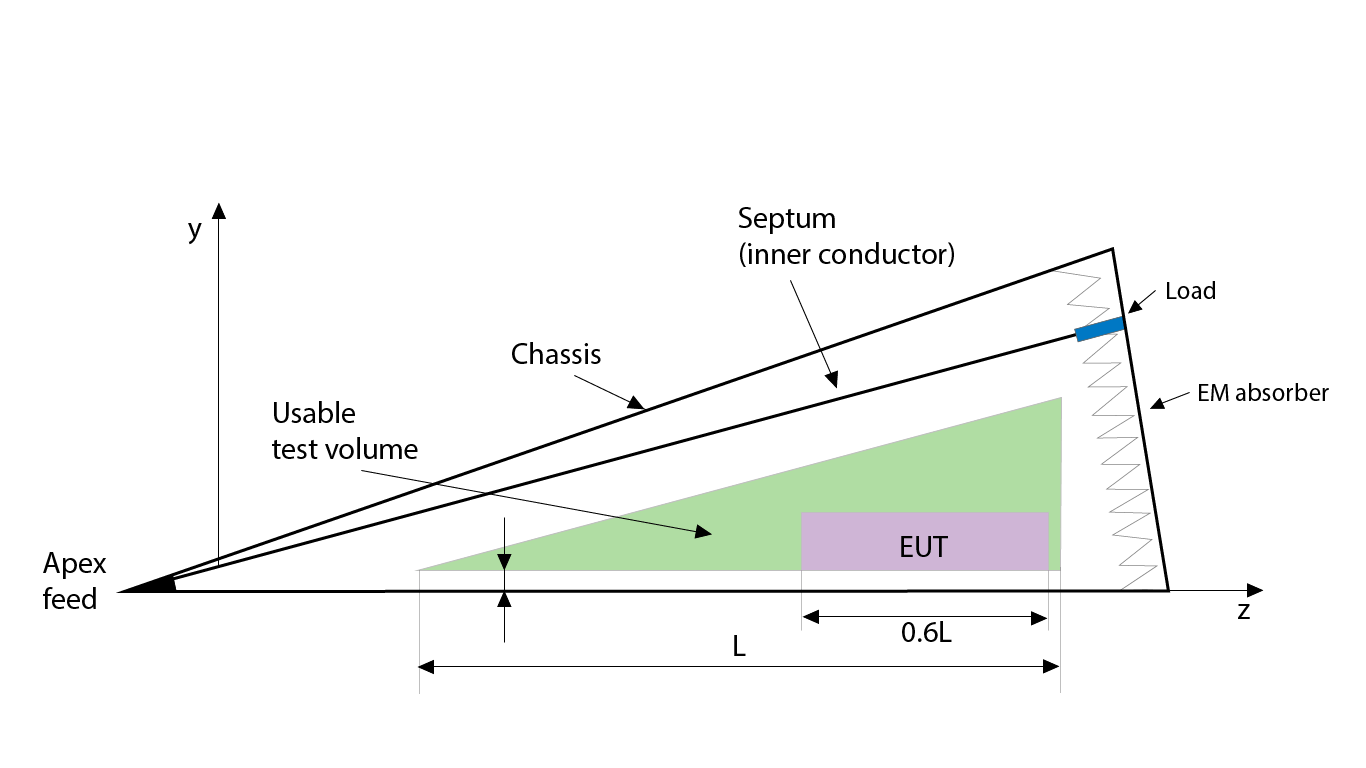

The cell uses a tapered transmission line that transitions seamlessly from a coaxial feed into the main test volume. This tapered architecture is the primary mechanism for minimising reflections and preventing standing waves, ensuring that measurement results remain consistent across a broad frequency spectrum. Because the internal environment is highly predictable, the GTEM serves as a reliable validation point between your initial prototype and the final certification phase.

GTEM vs TEM Cells

While legacy TEM cells were once the primary standard for EMC testing, they generally hit a ceiling at around 1 GHz. In a world of 5G, high-speed Wi-Fi and sophisticated IoT, those parameters are no longer sufficient. GTEM cells extend the transverse electromagnetic concept into the multi-gigahertz range, supporting the high-frequency requirements of modern wireless and digital systems.

The Anatomy of a GTEM Cell - Apex, Septum and Absorbers

A GTEM Cell can be broken down into four primary structural components:

- The Apex: The precise point where the RF signal enters the cell via a coaxial connector

- The Septum (inner conductor): A conductive inner plate that guides the electromagnetic wave through the chamber

- The Absorbers (EM absorber): Specialised carbon-loaded pyramids at the rear that "soak up" waves to prevent reflections, simulating an infinite transmission line

- The Load: A termination network that manages low-frequency energy

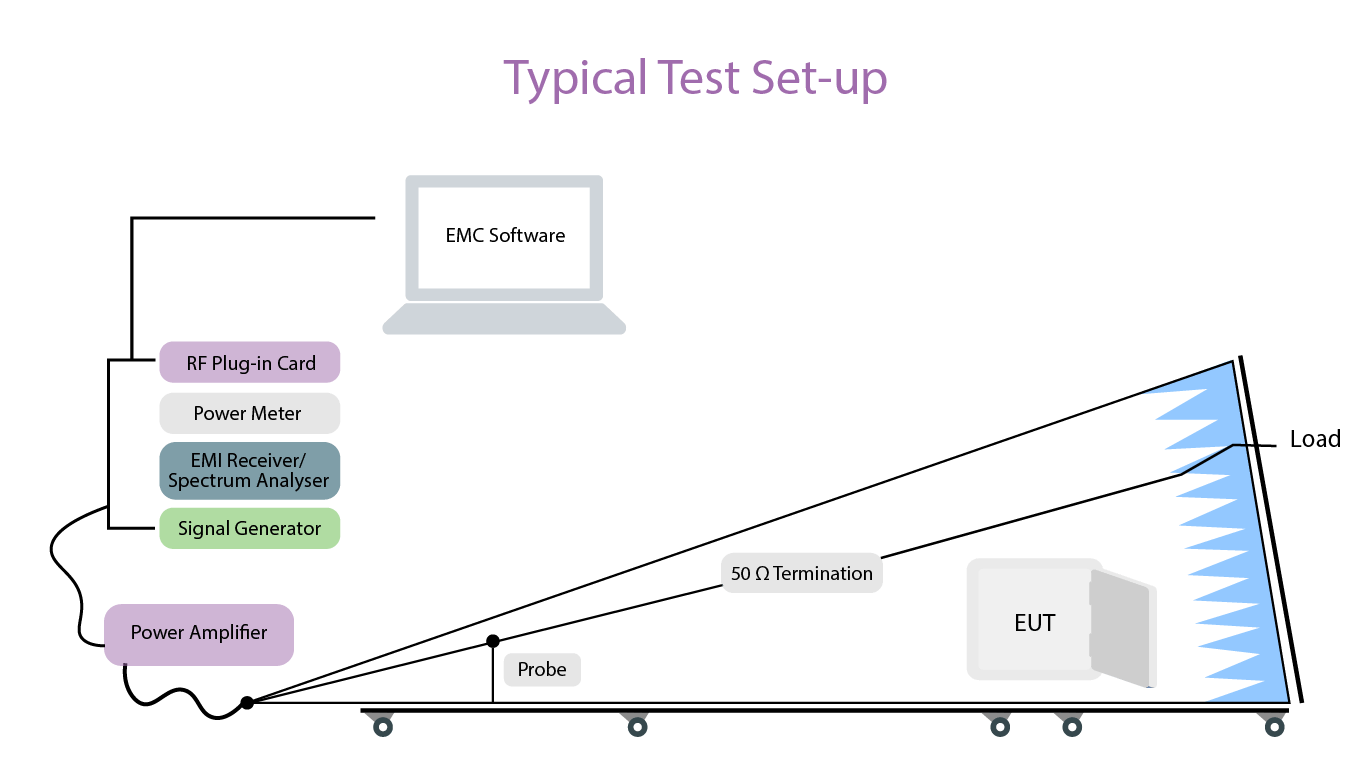

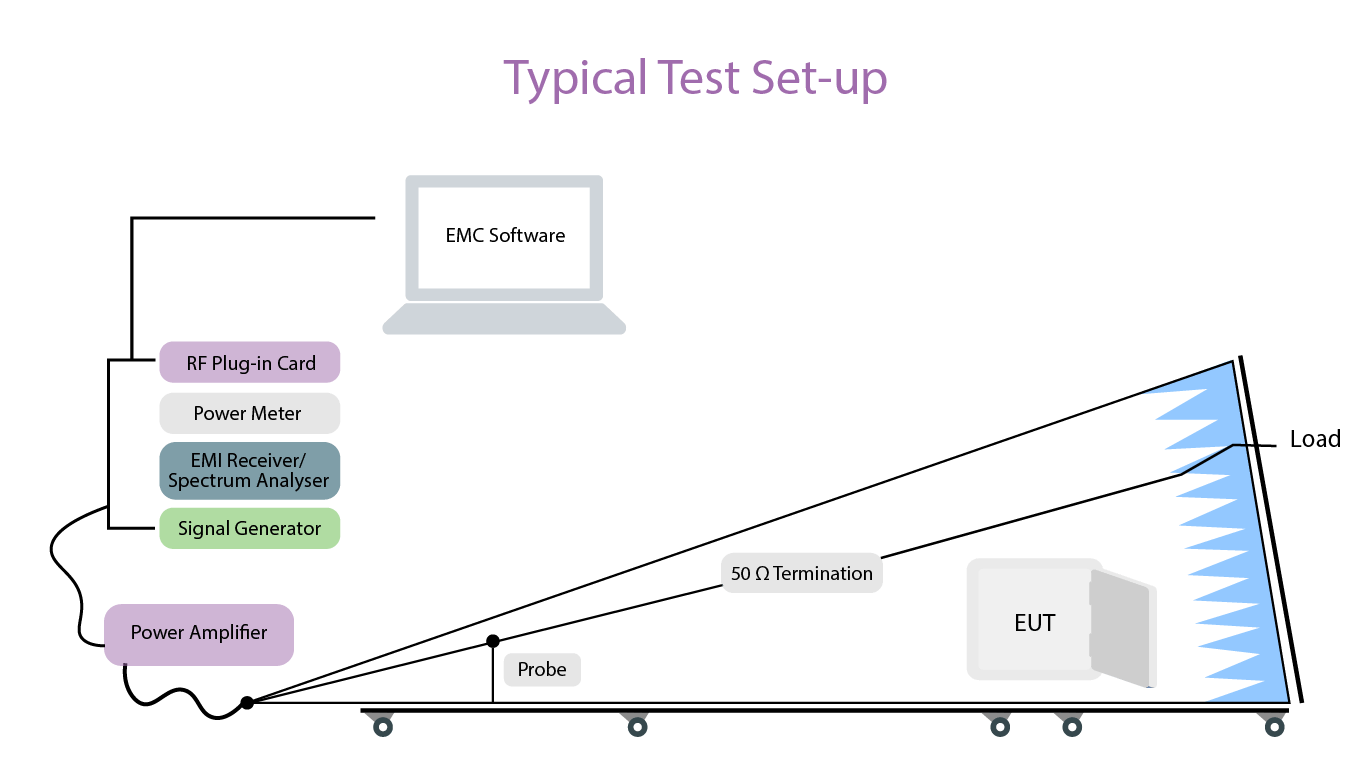

GTEM Cell Setup for Radiated Emissions and Immunity Testing

For radiated emissions testing, the equipment under test (EUT) is positioned on a non-conductive table inside the GTEM cell, typically below the septum within the defined test volume. Emissions generated by the EUT are coupled into the cell and measured at the apex port using a spectrum analyser or EMI receiver. A 50 Ω termination at the rear of the cell reduces reflections and supports stable, repeatable measurements. The EUT is operated in representative modes and measured in multiple orientations to identify peak emission levels, with results commonly correlated to OATS or anechoic chamber data.

For radiated immunity testing, the EUT is exposed to a controlled electromagnetic field generated within the GTEM cell. An RF signal is injected via the apex port using a signal generator and power amplifier and field levels are increased in defined steps while the EUT operates in normal functional modes. Performance is monitored throughout the test to identify any degradation or loss of function.

Together, these setups allow engineers to evaluate EMC performance efficiently and consistently before products are submitted for formal testing in larger EMC environments.

Bridging the Gap with the Correlation Algorithm and Achieving Pre-Certification

A common technical inquiry across the EMC industry:

"Can I truly compare GTEM results to a formal 3-meter chamber?"

The answer is in the Correlation Algorithm. By measuring your Equipment Under Test (EUT) in three orthogonal positions (and) software like RadiMation® calculates the total radiated power.

This data is then mathematically translated into an equivalent OATS (Open Area Test Site) or Anechoic Chamber value. This ensures that your internal data isn’t just a "rough guess," but a pre-certification which aligns with lab expectations.

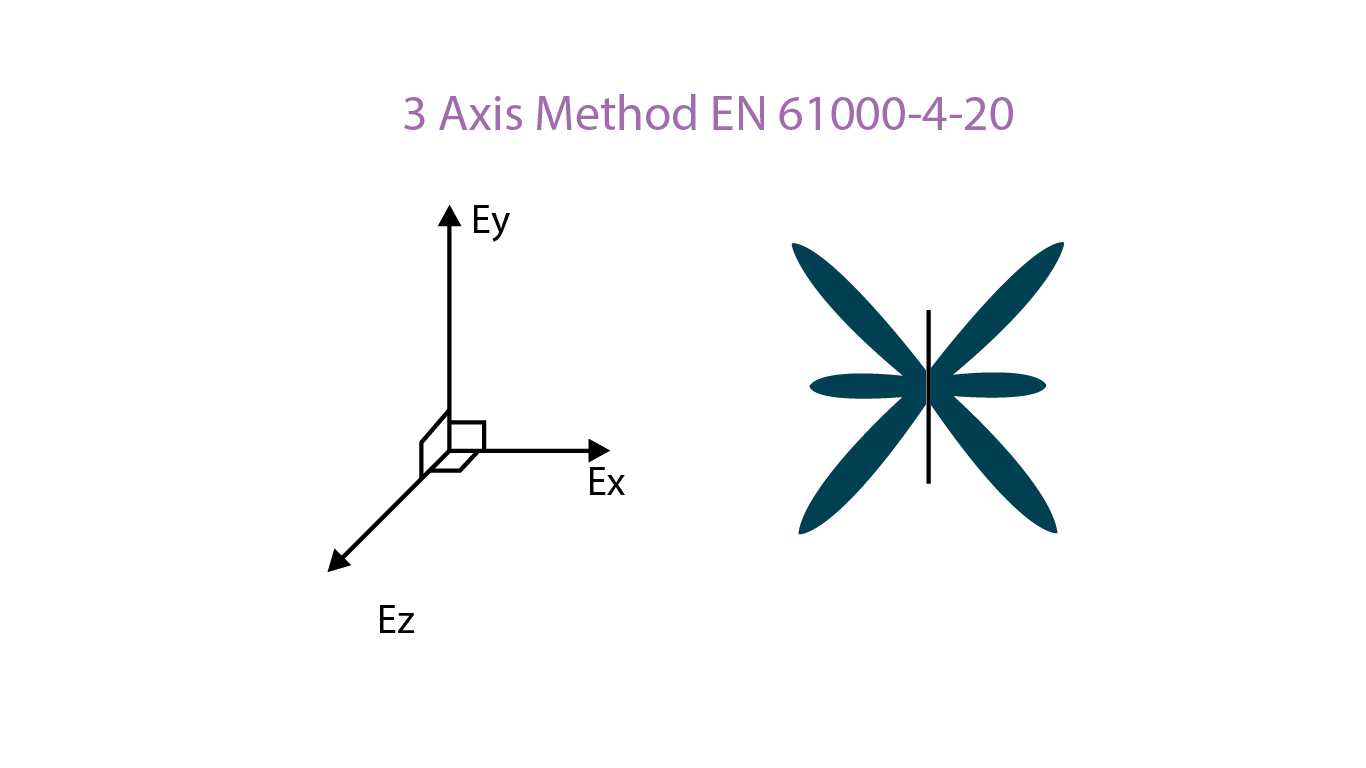

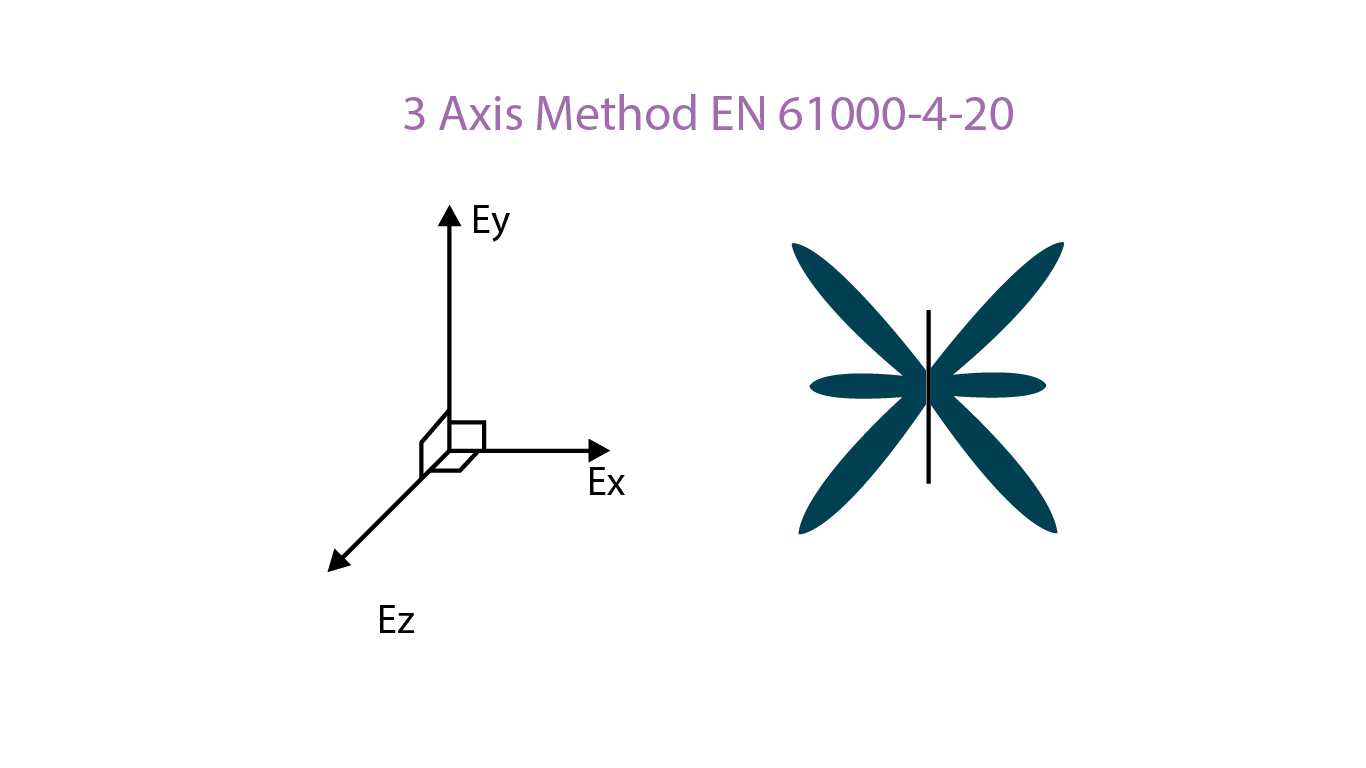

The 3-Axis Orthogonal Strategy

To achieve this accuracy, you must rotate your EUT into three positions:

- Vertical (Y): Facing the septum

- Side (X): Facing the lateral wall

- Longitudinal (Z): Facing the apex

Why Choose a GTEM Cell for Your In-House Lab?

In EMC testing, delays and late-stage failures are rarely caused by a lack of engineering capability. More often, they come from limited access to test facilities and discovering issues only when a product reaches an external test laboratory. This “fail-at-the-lab” cycle can quickly lead to redesign work, repeat test bookings and extended time to market.

For this reason, GTEM cells are a faultless solution for organisations that want greater control over EMC testing throughout development. By enabling accurate radiated emissions and radiated immunity testing in-house, GTEM cells help teams build confidence in product performance long before formal certification testing begins.

GTEM testing is aligned with recognised standards such as EN 61000-4-20 for both emissions and immunity, ensuring that results are relevant and comparable to those generated in accredited test environments. This standards-based approach is critical for reducing uncertainty and avoiding unexpected outcomes when products are finally assessed at a test laboratory.

Key Benefits:

- Pre-Certification & Full Compliance: While often used for pre-certification, GTEM cells are fully compliant with standards like EN/IEC 61000-4-20 for both immunity and emissions

- Space Efficiency: A GTEM cell providing the same test volume as a small chamber occupies only a fraction of the floor space

- Turnkey Integration: Modern systems, such as the Raditeq GTEM Bundles, integrate the cell with signal generators, power meters and EMC software for a seamless workflow

Avoid the 'Fail-at-the-lab' Cycle and Reduce Time-to-market with Raditeq GTEM Cell Solutions

'Lab-in-a-Box' Solution

For small to medium-sized enterprises, the path to market is often blocked by the high cost and long lead times of external test houses. The Raditeq GTEM Bundles are engineered specifically to dismantle these barriers, offering a turnkey "lab-in-a-box" that scales with your product line.

Space-Efficient Testing Without Compromising Accuracy

These bundles provide everything you need to conduct both radiated immunity and radiated emissions tests. Each package integrates the cell with signal sources and power measurement hardware.

Why This Matters for Your Development Cycle

- Catch Issues Early: Most redesign costs stem from discovering non-compliance at the very end of the project. By testing from the prototyping phase through to production, you catch noisy traces or shielding leaks when they are easiest to fix.

- Accelerate Time-to-Market: External test centers often have backlogs spanning months. Having an in-house Raditeq setup means you test on your schedule, keeping your project momentum high.

- Significant Cost Savings: A semi-anechoic chamber is a massive capital investment. These bundles offer a cost-effective alternative that mimics real-world environments, preventing the drain of repeat lab fees and the "fail-at-the-lab" cycle.

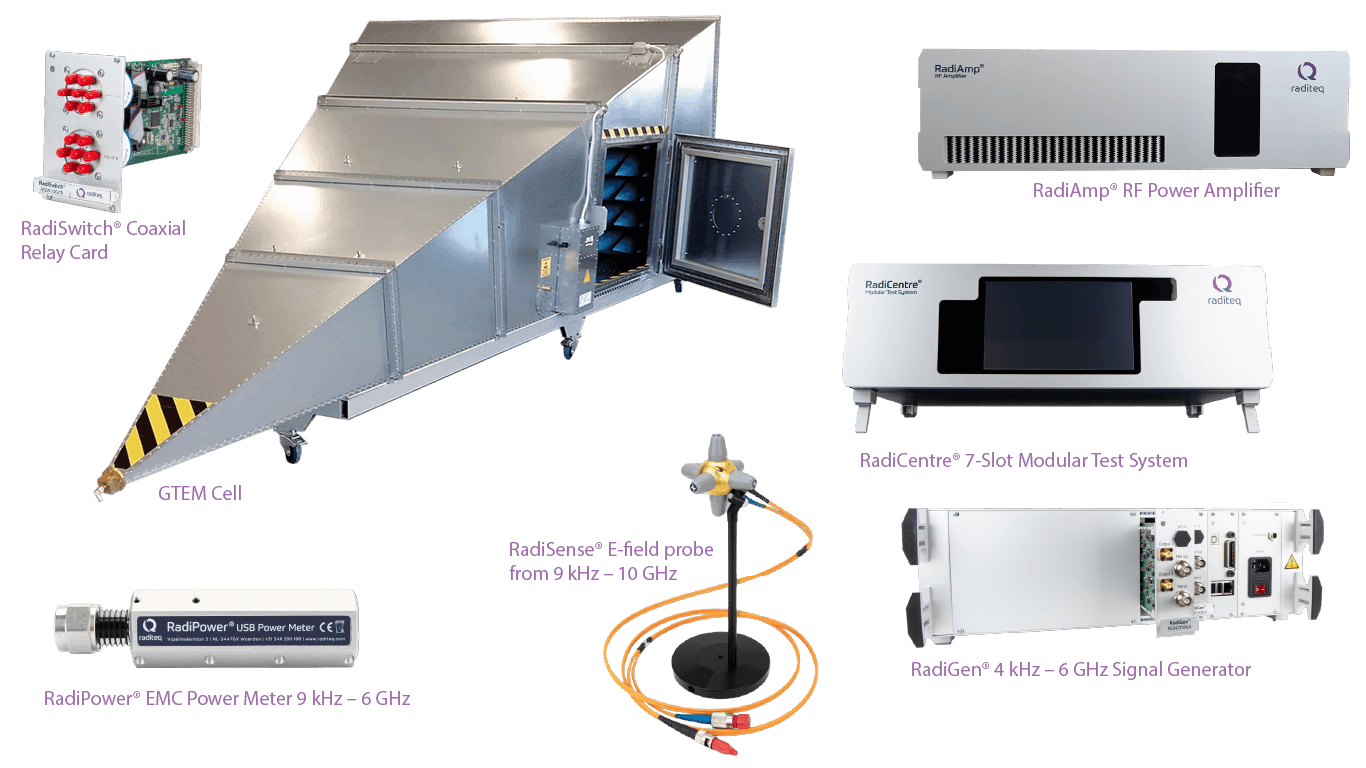

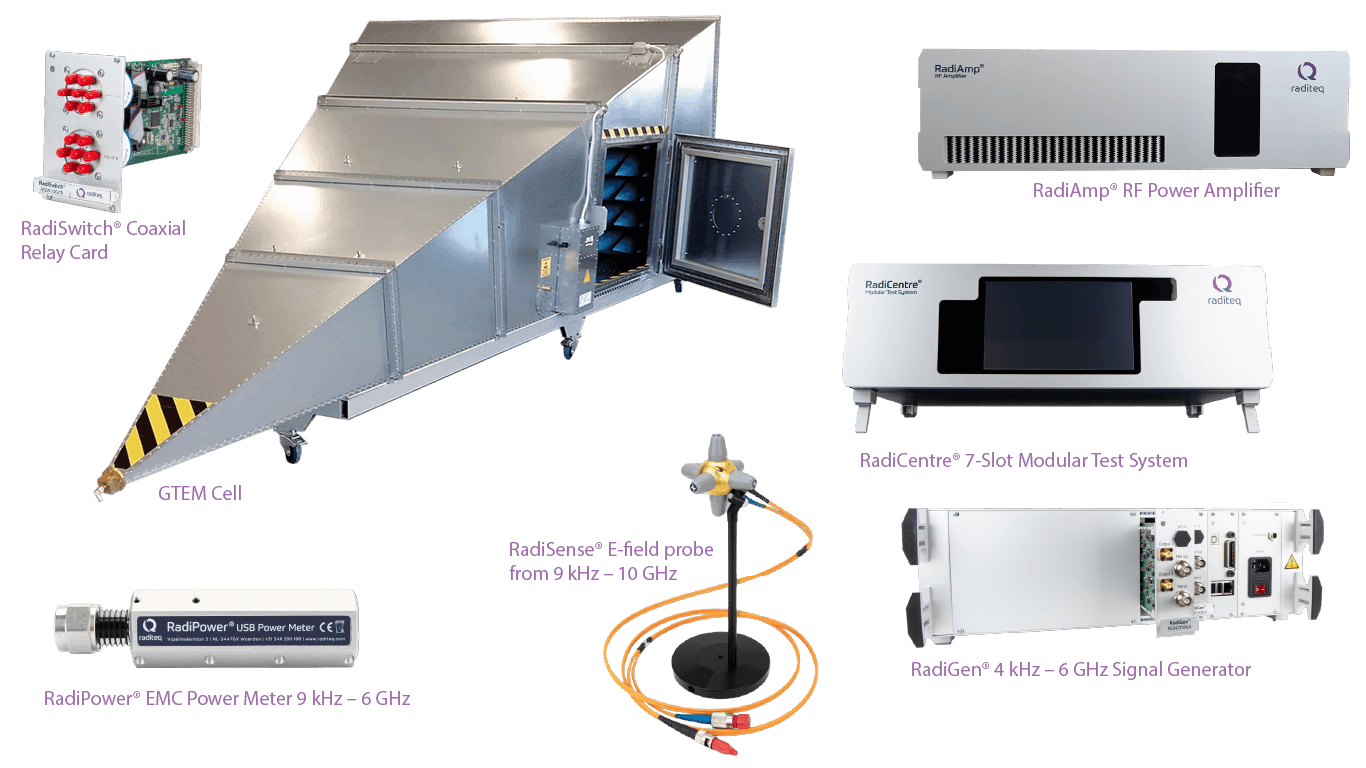

Raditeq GTEM Cell Bundle

What's in the box?

The Radiated Immunity GTEM Cell bundle consists of:

- RadiMation® | Automated EMC Test Software

- RadiCentre® | 7-slot Modular Test System

- RadiGen® | 4 kHz – 6 GHz Signal Generator

- RadiAmp® | RF Power Amplifier

- RadiPower® | EMC Power Meters 9 kHz – 6 GHz

- RadiSense® | E-field Probe from 9 kHz – 10 GHz

- RadiSwitch® |Coaxial Relay Card

- GTEM Cell – 250 – 550 – 1100 mm

- Including 19-inch Rack & Power Distribution

- All required cabling

(Note: For emissions, our team can help you verify if your existing spectrum analyser is compatible.)

Selecting the Right configuration of your GTEM Cell

Choosing the correct GTEM cell is largely driven by the size of the Equipment Under Test (EUT). To maintain field uniformity, the height of the EUT should not exceed one-third of the septum height, often referred to as the 1/3 rule. Applying this guideline ensures that test results remain reliable, supporting confident decision-making throughout development. Raditeq GTEM Bundles are available in multiple sizes to accommodate a wide range of applications, from compact IoT devices to larger industrial and automotive products.

Raditeq GTEM Bundles are availble in three distinct sizes to match your EUT:

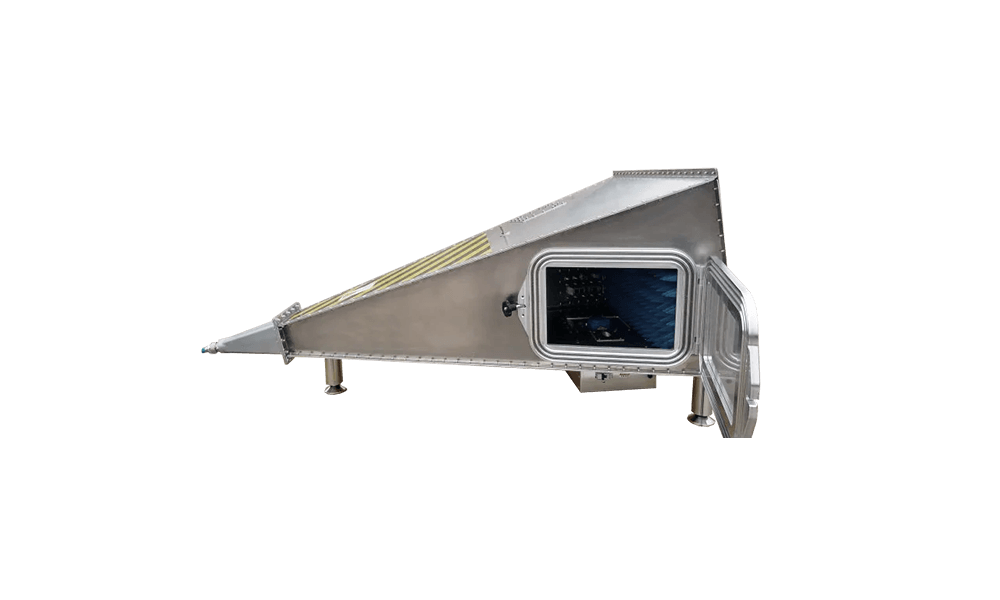

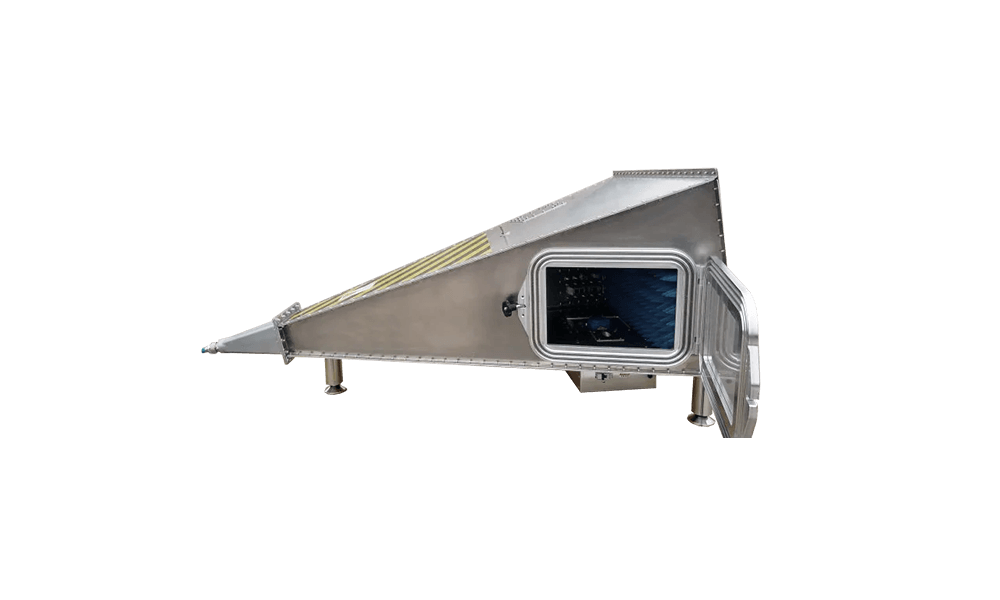

GTEM Cell RGT0250A

Specifications:

- Model: RGT0250A

- Range: 80 MHz to 6 GHz

- Test Level: 30 V/m

- Septum Height: 250 mm

- Max EUT size (LxWxH): 200 x 200 x 150 mm

GTEM Cell RGT0500A

Specifications:

- Model: RGT0200A

- Range: 80 MHz to 6 GHz

- Test Level: 30 V/m

- Septum Height: 500 mm

- Max EUT size (LxWxH): 410 x 410 x 300 mm

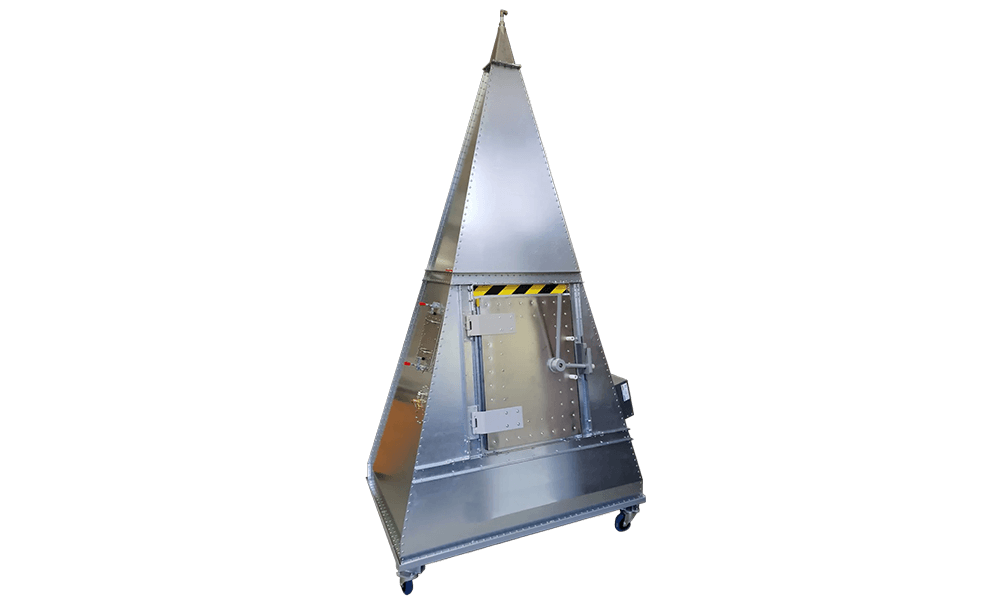

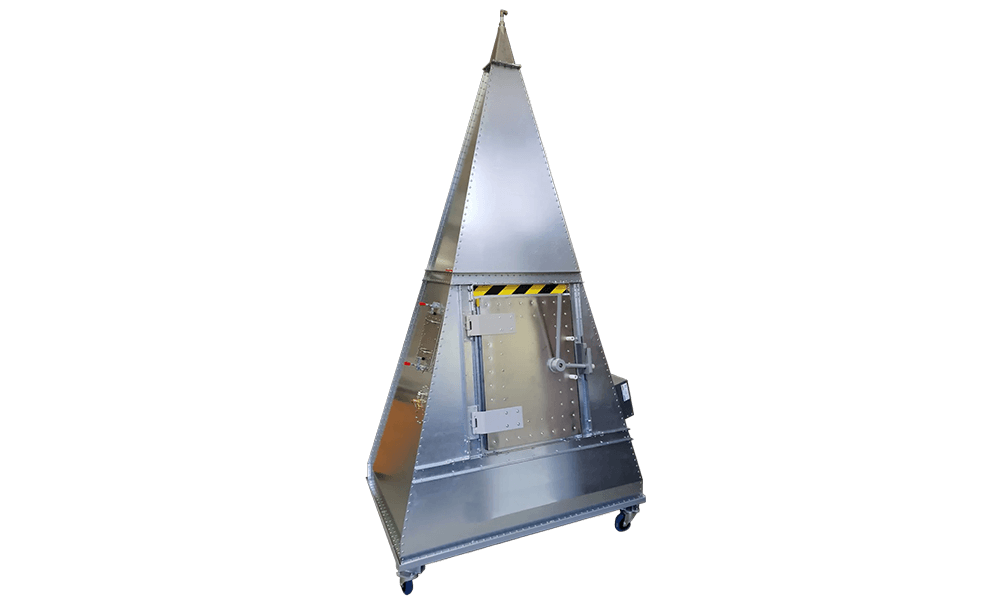

GTEM Cell RGT01100A

Specifications:

- Model: RGT1100A

- Range: 80 MHz to 6 GHz

- Test Level: 18 V/m

- Septum Height: 1100 mm

- Max EUT size (LxWxH): 790 x 790 x 550 mm

Bring EMC Testing In-house with APC

You only get one chance at a first-time pass. By bringing EMC testing in-house, your engineering team can identify weaknesses early, verify fixes quickly and avoid the costly cycle of failed test-house visits. APC provides GTEM test setups, expert guidance and equipment demonstrations, helping you build a reliable, safe and cost-effective EMC test environment.

Below are some examples of how APC can support you with your test setup and equipment requirements to fit your long-term testing needs.

|

One-time equipment cost |

|

|

Immediate testing, no scheduling |

|

|

Test immediately after every design change |

|

|

Real-time, unlimited |

|

|

Controlled and repeatable |

|

|

Development, troubleshooting and pre-compliance |

EMC Chambers, Shielded Enclosures and In-House EMC Lab Consultancy by APC

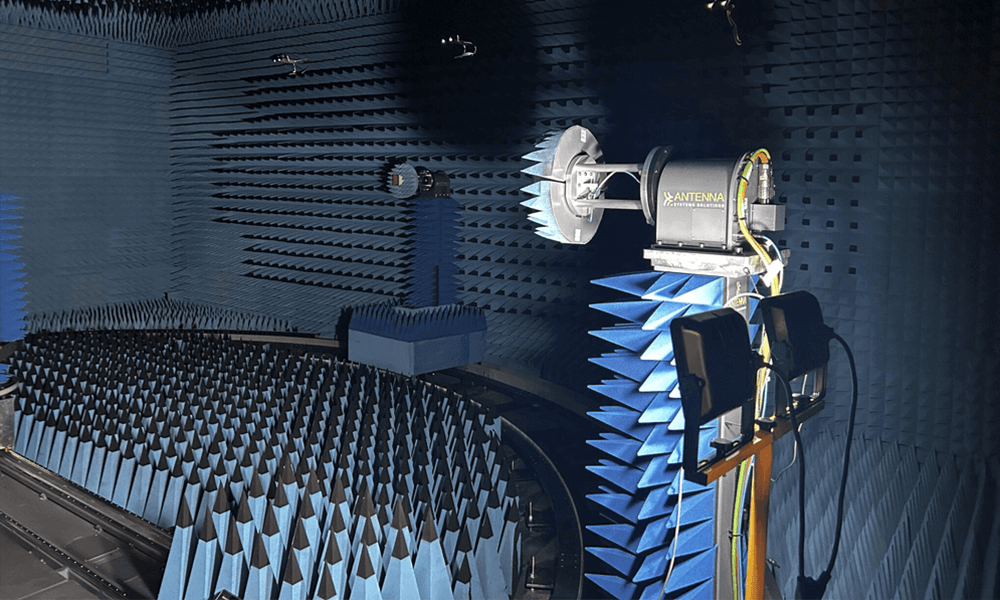

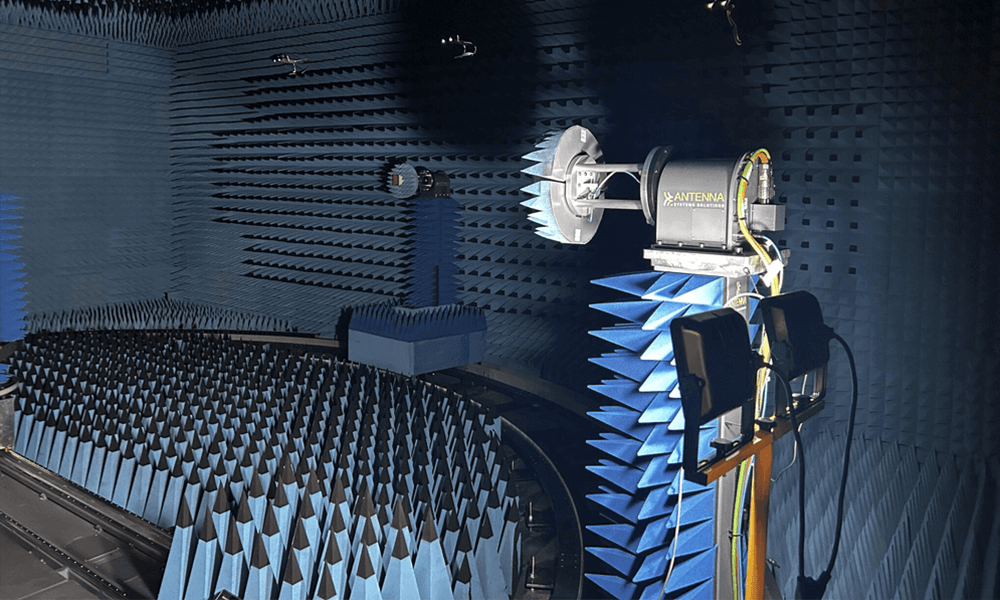

Anechoic Chambers

RF-absorbing chambers simulate free-space conditions for accurate antenna & emissions tests.

Shielded Rooms

Designed to prevent the entry or exit of electromagnetic radiation for clean measurements.

FAC & SAC vs. OATS

Compare Full Anechoic Chambers, Semi-Anechoic Chambers and Open Area Test Sites.

In-House Lab Consultancy

Consultancy services, through to the design, installation and testing phase to ensure your project runs smoothly.

EMC Radiated, Conducted & Immunity & Transient Test Equipment

Get expert advice

Request a callback from a member of our technical team to get dedicated one-to-one consultancy for EMC Testing, in-house capability and compliance.

Ready to bring EMC testing in-house with a GTEM Cell?

Whether you're starting from scratch or upgrading an existing test area, APC supplies the equipment you need to run EMC testing in-house.

From bespoke test chambers and GTEM cells to test and measurement equipment and RF systems, APC work with customers directly to reduce outsourcing costs, shorten development cycles and gain full control over pre-compliance testing.

Your Partner for Reliable and Compliant EMC Testing Solutions

With 40+ years supporting the electronics industry, APC provides high-reliability components, test equipment and engineering support for organisations building or expanding their EMC and test capabilities. As an authorised distributor for 100+ specialist manufacturers, we supply genuine, traceable equipment backed by recognised certifications.

Key Standards and Compliance for GTEM Cells

EN 61000-4-20: Electromagnetic compatibility (EMC) - Testing and measurement techniques. Emission and immunity testing in transverse electromagnetic (TEM) waveguides

EN 61000-4-3 (Annex D): Electromagnetic compatibility (EMC) - Testing and measurement techniques. Radiated, radio-frequency, electromagnetic field immunity test

SAE J1752/3: Measurement of Radiated Emissions from Integrated Circuits—TEM/Wideband TEM (GTEM) Cell Method; TEM Cell (150 kHz to 1 GHz), Wideband TEM Cell (150 kHz to 8 GHz)

IEC 61967-2: Measurement of electromagnetic emissions, 150 kHz to 1 GHz - Part 2: Measurement of radiated emissions - TEM cell and wideband TEM cell method

EN 62132-2: Measurement of electromagnetic immunity - Measurement of radiated immunity. TEM cell and wideband TEM cell method

Radiated emissions testing - Frequently Asked Questions (FAQs)

What are the regulatory standards for GTEM Cells?

The primary standard for GTEM cell measurements is IEC 61000-4-20 (often replacing older guidance in EN 61000-4-3).

What is the frequency range of GTEM cells?

DC to 20 GHz - The frequency range is from DC to 20 GHz. The best performance is achieved in the range 80 to 1000 MHz. FAR (Fully Anechoic Room) requires an amplifier with 100 W for 10 V/m. A GTEM 750 requires only 7.3 W.

How does a GTEM cell differ from an anechoic chamber?

GTEM cells and anechoic chambers are both used for EMC testing, but they differ significantly in size, cost and methodology. GTEM cells are compact, cost-effective and ideal for rapid radiated emissions/immunity testing of small devices. Anechoic chambers provide a large, fully shielded environment for simulating free-space conditions for larger, compliant or high-power systems.

What are the key uses and applications of a GTEM Cell?

Radiated Emission (RE) testing, radiated immunity (RI) testing, pre-compliance/certification and troubleshooting, antenna/sensor calibration, biomedical/biological research and components testing.

Where can I find suppliers of GTEM cells in the UK?

You can source GTEM cells in the UK directly from APC. Following our acquisition of MDL Technologies in 2021, we now provide a complete portfolio of EMC test environments and EMC equipment to customers across the UK and Northern Ireland.